Page 91: of Offshore Engineer Magazine (Apr/May 2014)

Read this page in Pdf, Flash or Html5 edition of Apr/May 2014 Offshore Engineer Magazine

During late February this year,

Vessels

Sembcorp Marine’s Singapore shipyard,

Jurong Shipyard, signed two contracts for

US$540 million each to build two drill- ships, with options for three additional units, from a subsidiary of Transocean.

Scheduled for delivery during 2Q 2017 and 1Q 2018, the Jurong Espadon III design represents the next generation of high-speci? cation drillships with advanced capabilities for operational ef? - ciency and ultra-deepwater development drilling operations worldwide. The drill- ships will be equipped with state-of-the- art drilling facilities, a large moonpool to cater for a larger riser angle, and bilge boxes designed for superior motion char- acteristics. The ships also feature larger deck space with enclosed riser bay and round mud pits inside the hull for opera- tional ef? ciency and safety. Equipped with DP3 capabilities, the drillships will

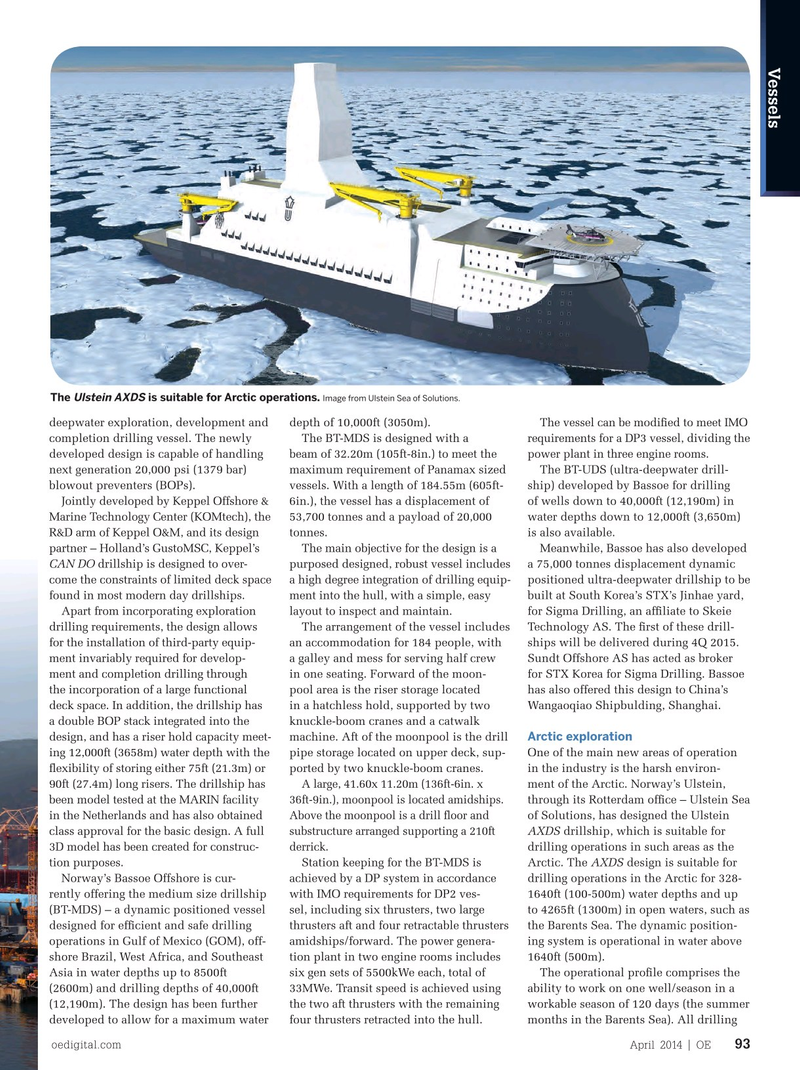

The is suitable for Arctic operations. Ulstein AXDS Image from Ulstein Sea of Solutions.

be able to operate in water depths up to

The vessel can be modi? ed to meet IMO 12,000ft (3658m) and drill to depths of deepwater exploration, development and depth of 10,000ft (3050m).

requirements for a DP3 vessel, dividing the 40,000ft (12,192m), with accommodation completion drilling vessel. The newly The BT-MDS is designed with a power plant in three engine rooms.

facilities for a crew of 220 personnel. developed design is capable of handling beam of 32.20m (105ft-8in.) to meet the

Another Singapore shipyard offer- next generation 20,000 psi (1379 bar) maximum requirement of Panamax sized The BT-UDS (ultra-deepwater drill- ing drillship designs is Keppel FELS, blowout preventers (BOPs). vessels. With a length of 184.55m (605ft- ship) developed by Bassoe for drilling a wholly-owned subsidiary of Keppel Jointly developed by Keppel Offshore & 6in.), the vessel has a displacement of of wells down to 40,000ft (12,190m) in

Offshore & Marine, which is proceed- Marine Technology Center (KOMtech), the 53,700 tonnes and a payload of 20,000 water depths down to 12,000ft (3,650m) ing witht the building of its new CAN R&D arm of Keppel O&M, and its design tonnes. is also available.

DO drillship. When completed, in 2016, partner – Holland’s GustoMSC, Keppel’s The main objective for the design is a Meanwhile, Bassoe has also developed the drillship will be a state-of-the-art CAN DO drillship is designed to over- purposed designed, robust vessel includes a 75,000 tonnes displacement dynamic come the constraints of limited deck space a high degree integration of drilling equip- positioned ultra-deepwater drillship to be found in most modern day drillships. ment into the hull, with a simple, easy built at South Korea’s STX’s Jinhae yard,

Apart from incorporating exploration layout to inspect and maintain. for Sigma Drilling, an af? liate to Skeie drilling requirements, the design allows The arrangement of the vessel includes Technology AS. The ? rst of these drill- for the installation of third-party equip- an accommodation for 184 people, with ships will be delivered during 4Q 2015. ment invariably required for develop- a galley and mess for serving half crew Sundt Offshore AS has acted as broker ment and completion drilling through in one seating. Forward of the moon- for STX Korea for Sigma Drilling. Bassoe the incorporation of a large functional pool area is the riser storage located has also offered this design to China’s deck space. In addition, the drillship has in a hatchless hold, supported by two Wangaoqiao Shipbulding, Shanghai. a double BOP stack integrated into the knuckle-boom cranes and a catwalk

Arctic exploration design, and has a riser hold capacity meet- machine. Aft of the moonpool is the drill ing 12,000ft (3658m) water depth with the pipe storage located on upper deck, sup- One of the main new areas of operation ? exibility of storing either 75ft (21.3m) or ported by two knuckle-boom cranes. in the industry is the harsh environ-

A large, 41.60x 11.20m (136ft-6in. x 90ft (27.4m) long risers. The drillship has ment of the Arctic. Norway’s Ulstein, 36ft-9in.), moonpool is located amidships. been model tested at the MARIN facility through its Rotterdam of? ce – Ulstein Sea

Above the moonpool is a drill ? oor and in the Netherlands and has also obtained of Solutions, has designed the Ulstein substructure arranged supporting a 210ft class approval for the basic design. A full AXDS drillship, which is suitable for derrick.

3D model has been created for construc- drilling operations in such areas as the tion purposes. Station keeping for the BT-MDS is Arctic. The AXDS design is suitable for

Norway’s Bassoe Offshore is cur- achieved by a DP system in accordance drilling operations in the Arctic for 328- rently offering the medium size drillship with IMO requirements for DP2 ves- 1640ft (100-500m) water depths and up (BT-MDS) – a dynamic positioned vessel sel, including six thrusters, two large to 4265ft (1300m) in open waters, such as designed for ef? cient and safe drilling thrusters aft and four retractable thrusters the Barents Sea. The dynamic position- operations in Gulf of Mexico (GOM), off- amidships/forward. The power genera- ing system is operational in water above shore Brazil, West Africa, and Southeast tion plant in two engine rooms includes 1640ft (500m).

Asia in water depths up to 8500ft six gen sets of 5500kWe each, total of The operational pro? le comprises the (2600m) and drilling depths of 40,000ft 33MWe. Transit speed is achieved using ability to work on one well/season in a (12,190m). The design has been further the two aft thrusters with the remaining workable season of 120 days (the summer developed to allow for a maximum water four thrusters retracted into the hull. months in the Barents Sea). All drilling oedigital.com April 2014 | OE 93 000_OE0414_Vessels2_Thorpe.indd 93 3/22/14 7:11 PM

90

90

92

92