Page 150: of Offshore Engineer Magazine (May/Jun 2014)

Read this page in Pdf, Flash or Html5 edition of May/Jun 2014 Offshore Engineer Magazine

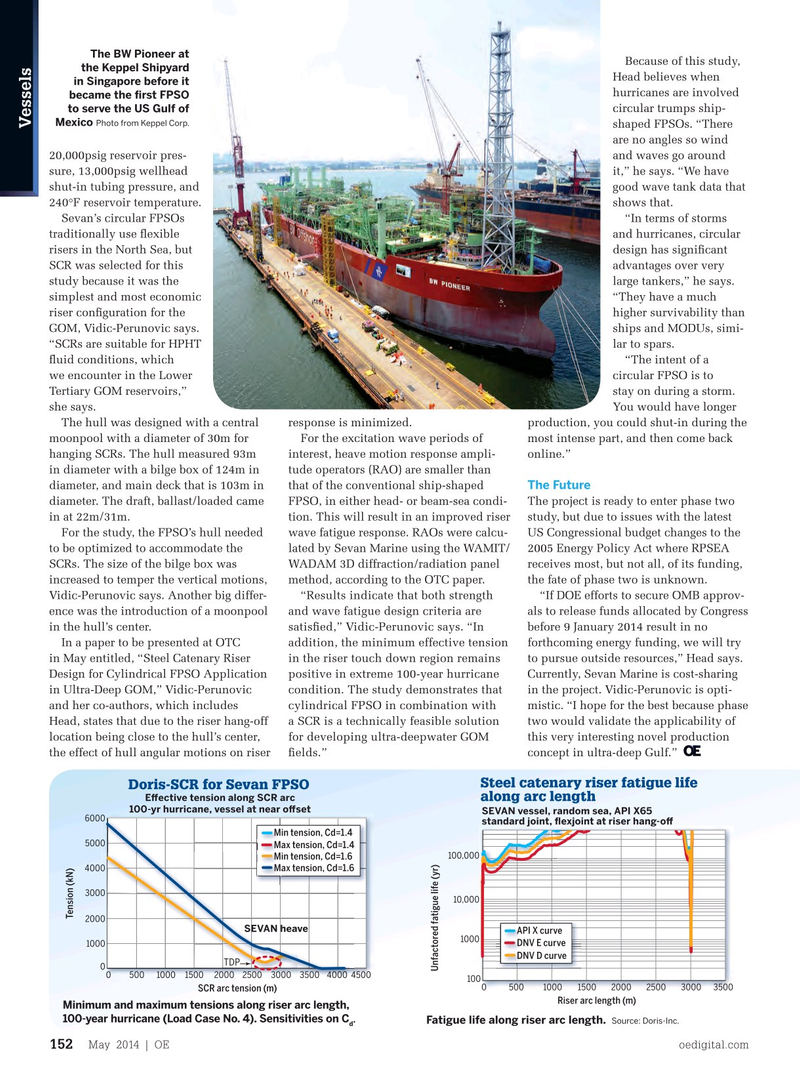

The BW Pioneer at

Because of this study, the Keppel Shipyard

Head believes when in Singapore before it hurricanes are involved became the ? rst FPSO circular trumps ship- to serve the US Gulf of

Mexico Photo from Keppel Corp.

shaped FPSOs. “There

Vessels are no angles so wind 20,000psig reservoir pres- and waves go around sure, 13,000psig wellhead it,” he says. “We have shut-in tubing pressure, and good wave tank data that 240°F reservoir temperature. shows that.

Sevan’s circular FPSOs “In terms of storms traditionally use ? exible and hurricanes, circular risers in the North Sea, but design has signi? cant

SCR was selected for this advantages over very study because it was the large tankers,” he says. simplest and most economic “They have a much riser con? guration for the higher survivability than

GOM, Vidic-Perunovic says. ships and MODUs, simi- “SCRs are suitable for HPHT lar to spars. ? uid conditions, which “The intent of a we encounter in the Lower circular FPSO is to

Tertiary GOM reservoirs,” stay on during a storm. she says. You would have longer

The hull was designed with a central response is minimized. production, you could shut-in during the moonpool with a diameter of 30m for For the excitation wave periods of most intense part, and then come back hanging SCRs. The hull measured 93m interest, heave motion response ampli- online.” in diameter with a bilge box of 124m in tude operators (RAO) are smaller than

The Future diameter, and main deck that is 103m in that of the conventional ship-shaped diameter. The draft, ballast/loaded came FPSO, in either head- or beam-sea condi- The project is ready to enter phase two in at 22m/31m. tion. This will result in an improved riser study, but due to issues with the latest

For the study, the FPSO’s hull needed wave fatigue response. RAOs were calcu- US Congressional budget changes to the to be optimized to accommodate the lated by Sevan Marine using the WAMIT/ 2005 Energy Policy Act where RPSEA

SCRs. The size of the bilge box was WADAM 3D diffraction/radiation panel receives most, but not all, of its funding, increased to temper the vertical motions, method, according to the OTC paper. the fate of phase two is unknown.

Vidic-Perunovic says. Another big differ- “Results indicate that both strength “If DOE efforts to secure OMB approv- ence was the introduction of a moonpool and wave fatigue design criteria are als to release funds allocated by Congress in the hull’s center. satis? ed,” Vidic-Perunovic says. “In before 9 January 2014 result in no

In a paper to be presented at OTC addition, the minimum effective tension forthcoming energy funding, we will try in May entitled, “Steel Catenary Riser in the riser touch down region remains to pursue outside resources,” Head says.

Design for Cylindrical FPSO Application positive in extreme 100-year hurricane Currently, Sevan Marine is cost-sharing in Ultra-Deep GOM,” Vidic-Perunovic condition. The study demonstrates that in the project. Vidic-Perunovic is opti- and her co-authors, which includes cylindrical FPSO in combination with mistic. “I hope for the best because phase

Head, states that due to the riser hang-off a SCR is a technically feasible solution two would validate the applicability of location being close to the hull’s center, for developing ultra-deepwater GOM this very interesting novel production the effect of hull angular motions on riser ? elds.” concept in ultra-deep Gulf.”

Steel catenary riser fatigue life

Doris-SCR for Sevan FPSO

E

149

149

151

151