Page 158: of Offshore Engineer Magazine (May/Jun 2014)

Read this page in Pdf, Flash or Html5 edition of May/Jun 2014 Offshore Engineer Magazine

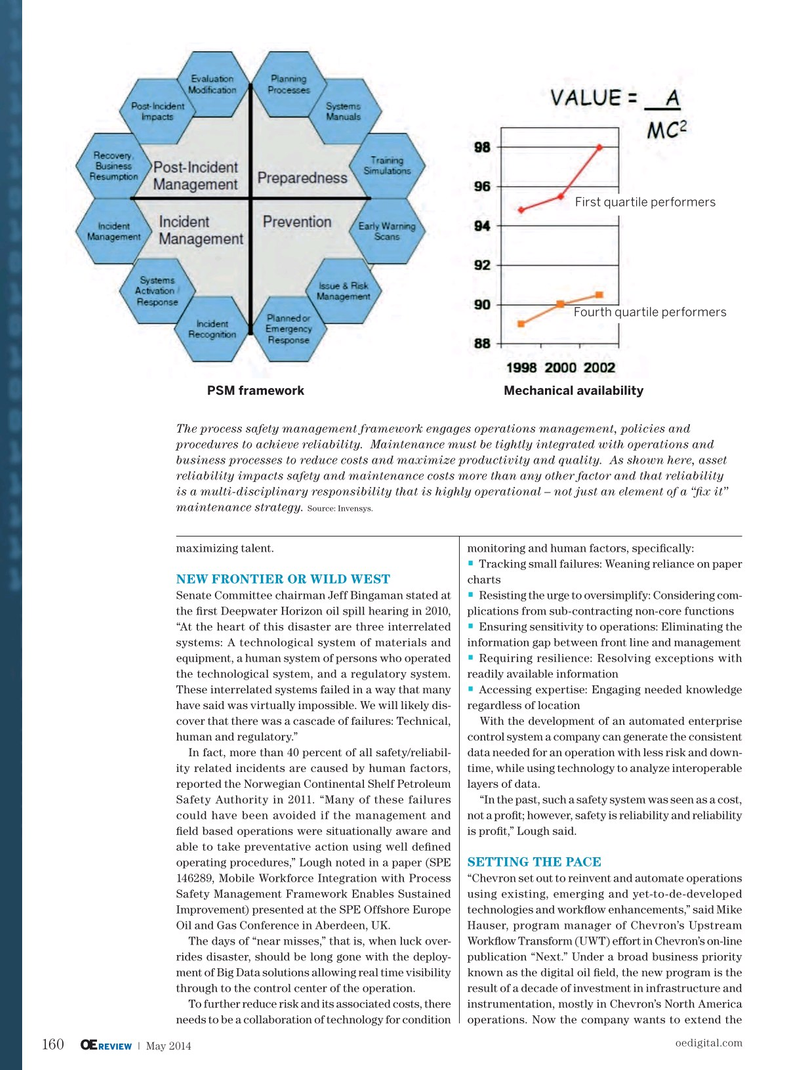

First quartile performers

Fourth quartile performers

PSM framework Mechanical availability

The process safety management framework engages operations management, policies and procedures to achieve reliability. Maintenance must be tightly integrated with operations and business processes to reduce costs and maximize productivity and quality. As shown here, asset reliability impacts safety and maintenance costs more than any other factor and that reliability is a multi-disciplinary responsibility that is highly operational – not just an element of a “? x it”

Source: Invensys.

maintenance strategy. maximizing talent. monitoring and human factors, speci? cally: • Tracking small failures: Weaning reliance on paper

NEW FRONTIER OR WILD WEST charts

Senate Committee chairman Jeff Bingaman stated at Resisting the urge to oversimplify: Considering com- • the ? rst Deepwater Horizon oil spill hearing in 2010, plications from sub-contracting non-core functions • “At the heart of this disaster are three interrelated Ensuring sensitivity to operations: Eliminating the systems: A technological system of materials and information gap between front line and management • equipment, a human system of persons who operated Requiring resilience: Resolving exceptions with the technological system, and a regulatory system. readily available information •

These interrelated systems failed in a way that many Accessing expertise: Engaging needed knowledge have said was virtually impossible. We will likely dis- regardless of location cover that there was a cascade of failures: Technical, With the development of an automated enterprise human and regulatory.” control system a company can generate the consistent

In fact, more than 40 percent of all safety/reliabil- data needed for an operation with less risk and down- ity related incidents are caused by human factors, time, while using technology to analyze interoperable reported the Norwegian Continental Shelf Petroleum layers of data.

Safety Authority in 2011. “Many of these failures “In the past, such a safety system was seen as a cost, could have been avoided if the management and not a pro? t; however, safety is reliability and reliability ? eld based operations were situationally aware and is pro? t,” Lough said.

able to take preventative action using well de? ned

SETTING THE PACE operating procedures,” Lough noted in a paper (SPE 146289, Mobile Workforce Integration with Process “Chevron set out to reinvent and automate operations

Safety Management Framework Enables Sustained using existing, emerging and yet-to-de-developed

Improvement) presented at the SPE Offshore Europe technologies and work? ow enhancements,” said Mike

Oil and Gas Conference in Aberdeen, UK. Hauser, program manager of Chevron’s Upstream

The days of “near misses,” that is, when luck over- Work? ow Transform (UWT) effort in Chevron’s on-line rides disaster, should be long gone with the deploy- publication “Next.” Under a broad business priority ment of Big Data solutions allowing real time visibility known as the digital oil ? eld, the new program is the through to the control center of the operation. result of a decade of investment in infrastructure and

To further reduce risk and its associated costs, there instrumentation, mostly in Chevron’s North America needs to be a collaboration of technology for condition operations. Now the company wants to extend the oedigital.com 160

OE | May 2014REVIEW 158_0514OER_Big_Data.indd 160 4/19/14 11:12 AM

157

157

159

159