Page 34: of Offshore Engineer Magazine (Jun/Jul 2014)

Read this page in Pdf, Flash or Html5 edition of Jun/Jul 2014 Offshore Engineer Magazine

Drilling

Archer’s modular Topaz makes its North Sea debut

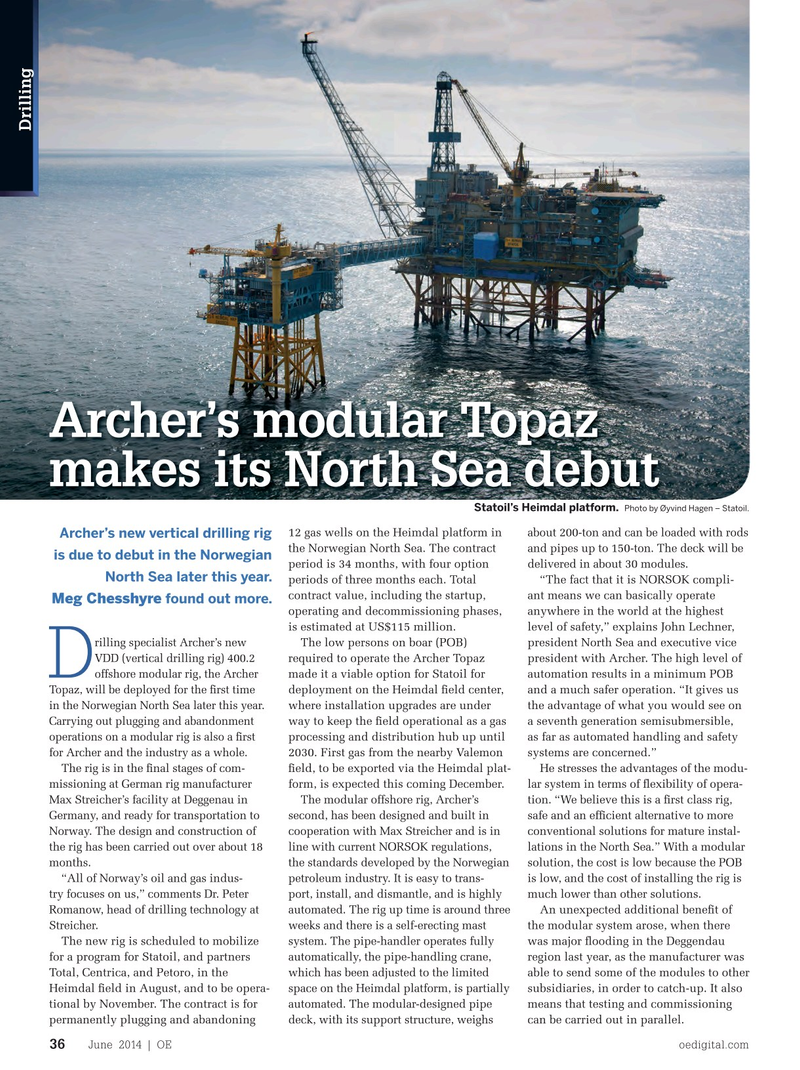

Statoil’s Heimdal platform. Photo by Øyvind Hagen – Statoil. 12 gas wells on the Heimdal platform in about 200-ton and can be loaded with rods

Archer’s new vertical drilling rig the Norwegian North Sea. The contract and pipes up to 150-ton. The deck will be is due to debut in the Norwegian period is 34 months, with four option delivered in about 30 modules.

North Sea later this year. periods of three months each. Total “The fact that it is NORSOK compli- contract value, including the startup, ant means we can basically operate

Meg Chesshyre found out more. operating and decommissioning phases, anywhere in the world at the highest is estimated at US$115 million. level of safety,” explains John Lechner, rilling specialist Archer’s new

The low persons on boar (POB) president North Sea and executive vice

VDD (vertical drilling rig) 400.2 required to operate the Archer Topaz president with Archer. The high level of

D offshore modular rig, the Archer made it a viable option for Statoil for automation results in a minimum POB

Topaz, will be deployed for the ? rst time deployment on the Heimdal ? eld center, and a much safer operation. “It gives us in the Norwegian North Sea later this year. where installation upgrades are under the advantage of what you would see on

Carrying out plugging and abandonment way to keep the ? eld operational as a gas a seventh generation semisubmersible, operations on a modular rig is also a ? rst processing and distribution hub up until as far as automated handling and safety for Archer and the industry as a whole. 2030. First gas from the nearby Valemon systems are concerned.”

The rig is in the ? nal stages of com- ? eld, to be exported via the Heimdal plat- He stresses the advantages of the modu- missioning at German rig manufacturer form, is expected this coming December. lar system in terms of ? exibility of opera-

Max Streicher’s facility at Deggenau in The modular offshore rig, Archer’s tion. “We believe this is a ? rst class rig,

Germany, and ready for transportation to second, has been designed and built in safe and an ef? cient alternative to more

Norway. The design and construction of cooperation with Max Streicher and is in conventional solutions for mature instal- the rig has been carried out over about 18 line with current NORSOK regulations, lations in the North Sea.” With a modular months. the standards developed by the Norwegian solution, the cost is low because the POB “All of Norway’s oil and gas indus- petroleum industry. It is easy to trans- is low, and the cost of installing the rig is try focuses on us,” comments Dr. Peter port, install, and dismantle, and is highly much lower than other solutions.

Romanow, head of drilling technology at automated. The rig up time is around three

An unexpected additional bene? t of

Streicher. weeks and there is a self-erecting mast the modular system arose, when there

The new rig is scheduled to mobilize was major ? ooding in the Deggendau system. The pipe-handler operates fully for a program for Statoil, and partners region last year, as the manufacturer was automatically, the pipe-handling crane,

Total, Centrica, and Petoro, in the able to send some of the modules to other which has been adjusted to the limited

Heimdal ? eld in August, and to be opera- subsidiaries, in order to catch-up. It also space on the Heimdal platform, is partially tional by November. The contract is for means that testing and commissioning automated. The modular-designed pipe permanently plugging and abandoning can be carried out in parallel.

deck, with its support structure, weighs

June 2014 | OE oedigital.com 36 036_OE0614_D&C3_Archer.indd 36 5/22/14 9:54 PM

33

33

35

35