Page 64: of Offshore Engineer Magazine (Jun/Jul 2014)

Read this page in Pdf, Flash or Html5 edition of Jun/Jul 2014 Offshore Engineer Magazine

in a 3x3 con? guration. Ma and

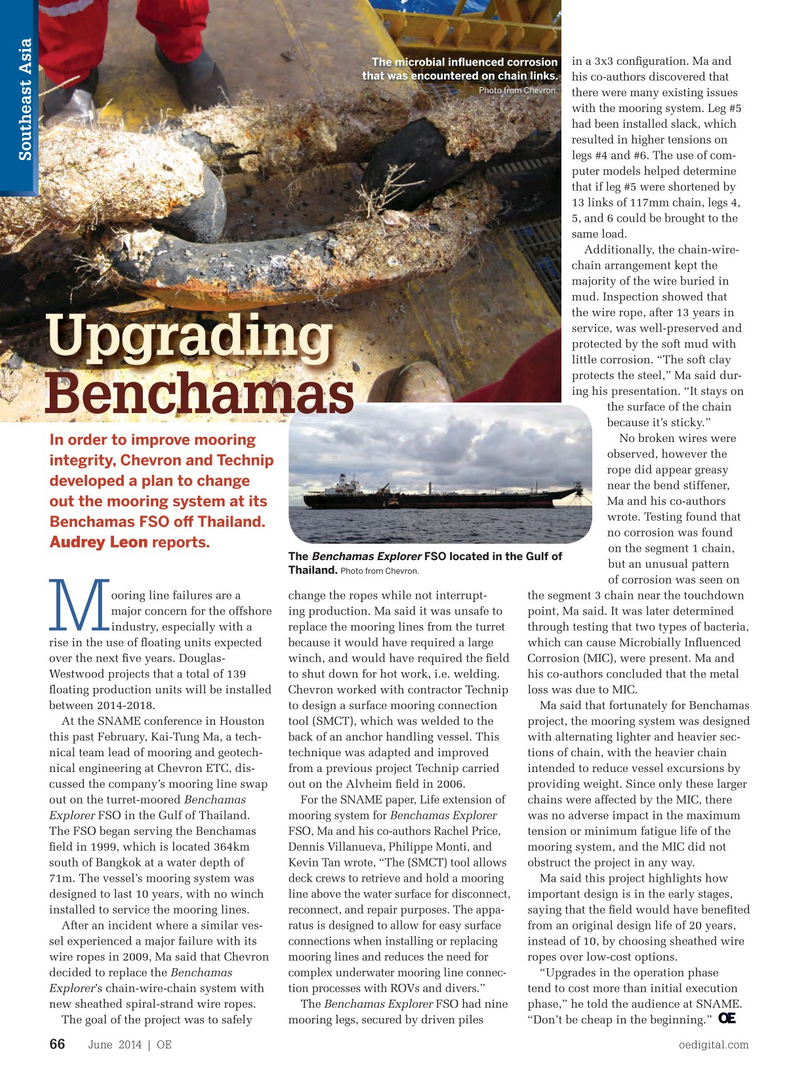

The microbial in? uenced corrosion that was encountered on chain links. his co-authors discovered that

Photo from Chevron.

there were many existing issues with the mooring system. Leg #5 had been installed slack, which resulted in higher tensions on legs #4 and #6. The use of com-

Southeast Asia puter models helped determine that if leg #5 were shortened by 13 links of 117mm chain, legs 4, 5, and 6 could be brought to the same load.

Additionally, the chain-wire- chain arrangement kept the majority of the wire buried in mud. Inspection showed that the wire rope, after 13 years in service, was well-preserved and protected by the soft mud with

UpgradingUpgrading little corrosion. “The soft clay protects the steel,” Ma said dur- ing his presentation. “It stays on the surface of the chain

Benchamas because it’s sticky.”

No broken wires were

In order to improve mooring observed, however the integrity, Chevron and Technip rope did appear greasy developed a plan to change near the bend stiffener,

Ma and his co-authors out the mooring system at its wrote. Testing found that

Benchamas FSO o

63

63

65

65