Page 23: of Offshore Engineer Magazine (Mar/Apr 2015)

Read this page in Pdf, Flash or Html5 edition of Mar/Apr 2015 Offshore Engineer Magazine

data issues, under the right economics, providing an alternative DSA road map

To illustrate the possible development pathway of drilling systems, to mud pulse telemetry, Macpherson says. a Drilling Systems Automation (DSA) Road Map initiative has been

Standardization put together under the af? liation of SPE, IADC and AUVSI.

DSATS is working to address some of the challenges in drilling The task has been split into eight groups: Systems architecture; automation – and allow smaller companies, or even companies Communications; Instrumentation and measurement; Drilling outside the oil industry, to provide solutions – by opening up machines; Control systems; Simulation and modeling systems; the communications systems and infrastructure “so everyone Human factors; and Certi? cation and Industry Standards.

When automation, can play.” Each of these groups is taking the individual subject areas

It has promoted a communications protocol (OPC-UA), which and mapping how the technology is likely to develop and then is being adopted by the industry. The protocol describes how bring it all together to see, as a whole, how they perceive it data moves between different objects, allowing a third party to going. This information would then be shared so that anyone not if safely plug in and provide applications to optimize the system. with business in this area can appreciate what direction the

DSATS is now working on a rig information model to allow technology is going. a third party to know what it is looking at when it plugs into a The idea is that the DSA road map can also identify technol- rig system. This would include environmental information and ogy gaps, which companies might decide to pursue. hardware limits, in order for the third party to control the rig

Inevitable automation equipment.

Once re? ned, the rig information model will be handed as Automation on the drill? oor has been slow to take off – but it is a recommendation to a third party, such as Energistics, who coming as advances in enabling technologies, such as downhole will build it into recommended guidelines for drilling systems communication links, as well as creating open architecture, are automation, and perhaps eventually into a standard. Energistics made. is responsible for WITSML, a web-based version of the Wellsite For Odd Erik Gundersen, associate professor, Department of

Information Transfer Speci? cation (WITS) a common communi- Computer and Information Science at the Norwegian University cation protocol. of Science and Technology, increasing automation in the drill-

A further piece of work is a security and threats model ing process is “inevitable,” and has the potential to achieve for connectivity, being created jointly between the SPE and consistent higher quality and safety. “To me it’s a no-brainer,”

International Association of Drilling Contractors (IADC). he told the SPE seminar.

But, he says automation will not solve everything, particularly

A further challenge is controls modeling, Macpherson says. when it comes to situational awareness or handling unexpected

While the capability exists to model complex systems, from events. He suggests a hybrid solution where computers can the bit up to the surface, modeling from a controls perspective make the main bulk of decisions that are non-exceptional and do is a challenge due to the many elements that in? uence system not require human creativity as part of the problem solving pro- behavior, which may or may not be known, Macpherson says.

cess, while the human is still involved in the complex decisions.

First, there is a requirement for high quality, reliable real-time data, then an understanding of measurement delays ,which wired “The business model is evolving and is certainly disruptive drill-pipe would help with, and then there is a need for real-time and transformative. You know automation is going to leave this modeling itself. “Our perspective on modeling has to change to industry changed, but what the change is and how it takes place a control point of view, a real-time point of view. So real-time is a story that is evolving,” Macpherson says. control – what measurements you make, how you close the loop,

For more information on DSATS how you model the system in real time - this is probably a little

FURTHER READING go to: http://connect.spe.org/ beyond us at the moment, but this area is beginning to evolve

DSATS/ and we certainly have the computer power to do it.”

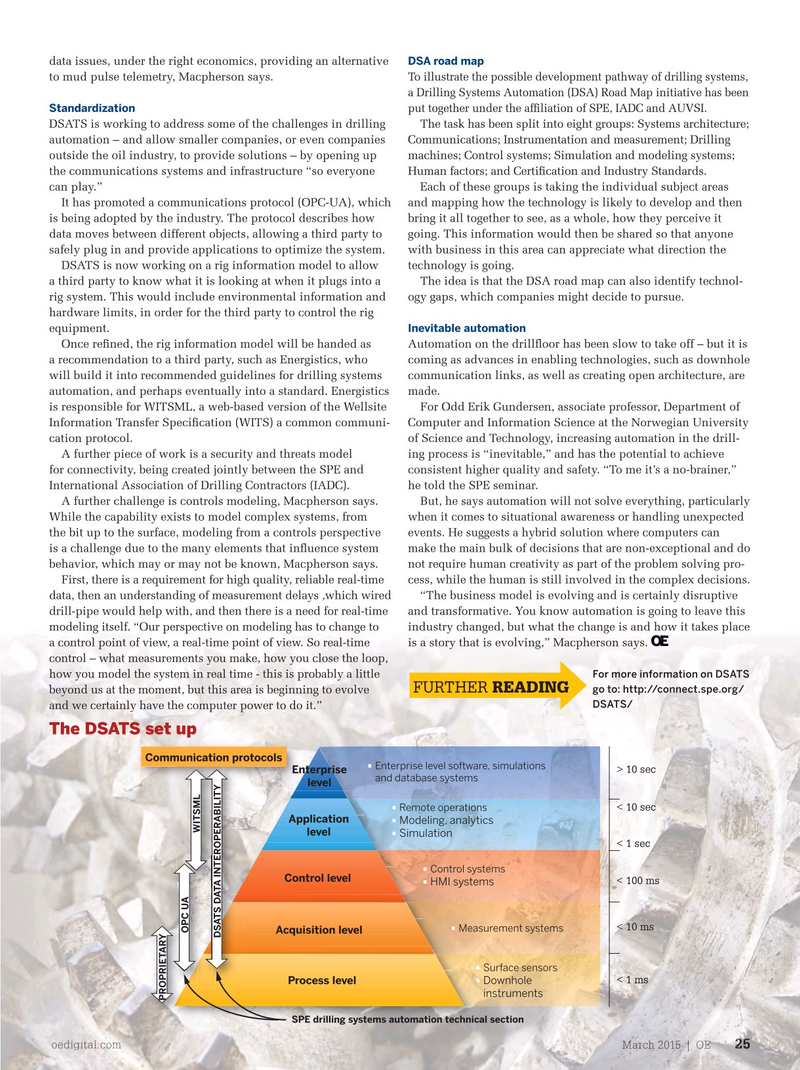

The DSATS set up

Communication protocols • Enterprise level software, simulations > 10 sec

Enterprise and database systems level • Remote operations < 10 sec

Application Modeling, analytics •

WITSML level Simulation • < 1 sec • Control systems

Control level < 100 ms • HMI systems < 10 ms • Measurement systems

OPC UA

Acquisition level

DSATS DATA INTEROPERABILITY • Surface sensors < 1 ms •

Process level Downhole instruments

PROPRIETARY

SPE drilling systems automation technical section oedigital.com March 2015 | OEoedigital.com March 2015 | OE 2525 024_OE0315_Feat3_DSATS.indd 25 2/22/15 12:16 PM

22

22

24

24