Page 44: of Offshore Engineer Magazine (Mar/Apr 2015)

Read this page in Pdf, Flash or Html5 edition of Mar/Apr 2015 Offshore Engineer Magazine

meant compiling a complete record of the construction detailing all non- conformities and preparing a full fnite element model of the hull and topsides in as-is condition on delivery to Total.

EyebrowProduction

The model is the platform for of an ongoing risk-based inspection (RBI) program and an AIM scheme provide by Bureau Veritas. It will use VeriSTAR

HLC software for tasks including inspec- tion of relevant structural areas, assess- ing the corrosion condition of the FPSO against BV or user-defned criteria, and managing the data on the structure and topsides over the long term in an open format.

A big part of any modern AIM system is risk assessment. As we gain experience with offshore foaters in harsh deepwater environments we build better knowledge

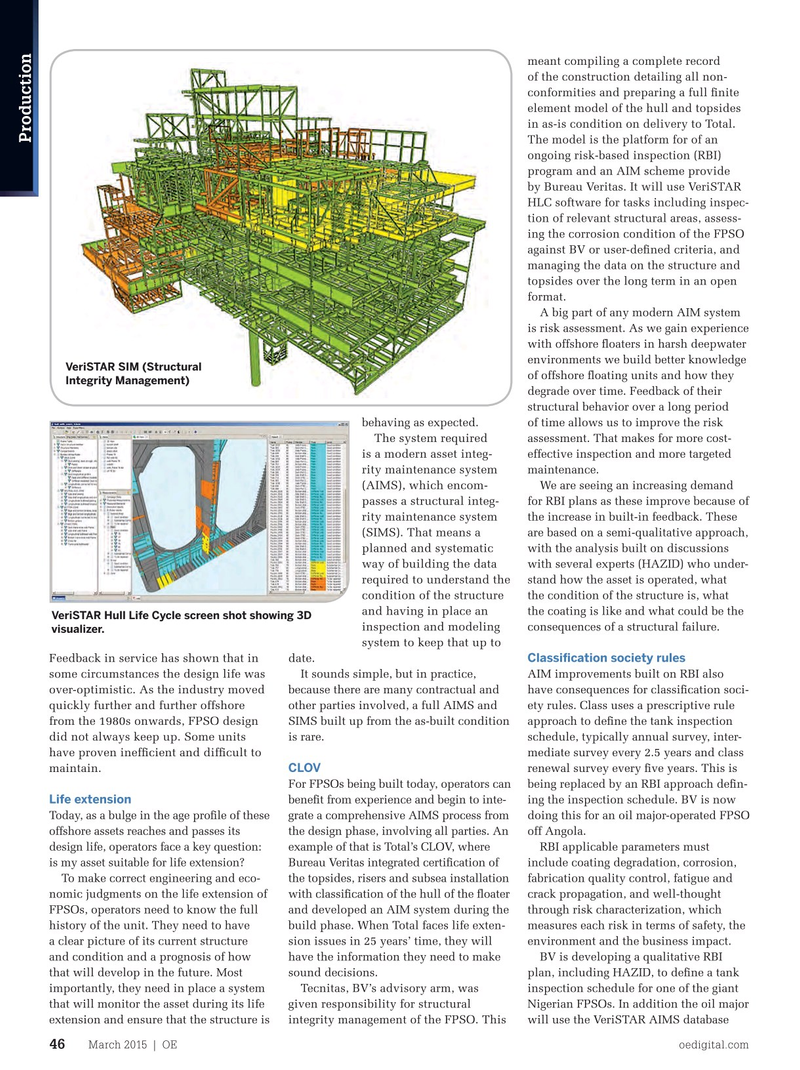

VeriSTAR SIM (Structural of offshore foating units and how they

Integrity Management) degrade over time. Feedback of their structural behavior over a long period behaving as expected. of time allows us to improve the risk

The system required assessment. That makes for more cost- is a modern asset integ- effective inspection and more targeted rity maintenance system maintenance.

(AIMS), which encom-

We are seeing an increasing demand passes a structural integ- for RBI plans as these improve because of rity maintenance system the increase in built-in feedback. These (SIMS). That means a are based on a semi-qualitative approach, planned and systematic with the analysis built on discussions way of building the data with several experts (HAZID) who under- required to understand the stand how the asset is operated, what

WE DELIVER ASSET condition of the structure the condition of the structure is, what and having in place an the coating is like and what could be the

VeriSTAR Hull Life Cycle screen shot showing 3D

INTEGRITY THROUGH inspection and modeling consequences of a structural failure.

visualizer.

system to keep that up to

SAFE, INNOVATIVE,

Feedback in service has shown that in Classifcation society rules date.

It sounds simple, but in practice, AIM improvements built on RBI also some circumstances the design life was

AND COST-EFFECTIVE because there are many contractual and have consequences for classifcation soci- over-optimistic. As the industry moved other parties involved, a full AIMS and ety rules. Class uses a prescriptive rule quickly further and further offshore

SIMS built up from the as-built condition approach to defne the tank inspection from the 1980s onwards, FPSO design

SOLUTIONS.

is rare. schedule, typically annual survey, inter- did not always keep up. Some units mediate survey every 2.5 years and class have proven ineffcient and diffcult to

CLOV renewal survey every fve years. This is maintain.

For FPSOs being built today, operators can being replaced by an RBI approach defn-

Life extension beneft from experience and begin to inte- ing the inspection schedule. BV is now

Today, as a bulge in the age profle of these grate a comprehensive AIMS process from doing this for an oil major-operated FPSO offshore assets reaches and passes its the design phase, involving all parties. An off Angola.

design life, operators face a key question: example of that is Total’s CLOV, where RBI applicable parameters must

We o

43

43

45

45