Page 25: of Offshore Engineer Magazine (Jun/Jul 2015)

Read this page in Pdf, Flash or Html5 edition of Jun/Jul 2015 Offshore Engineer Magazine

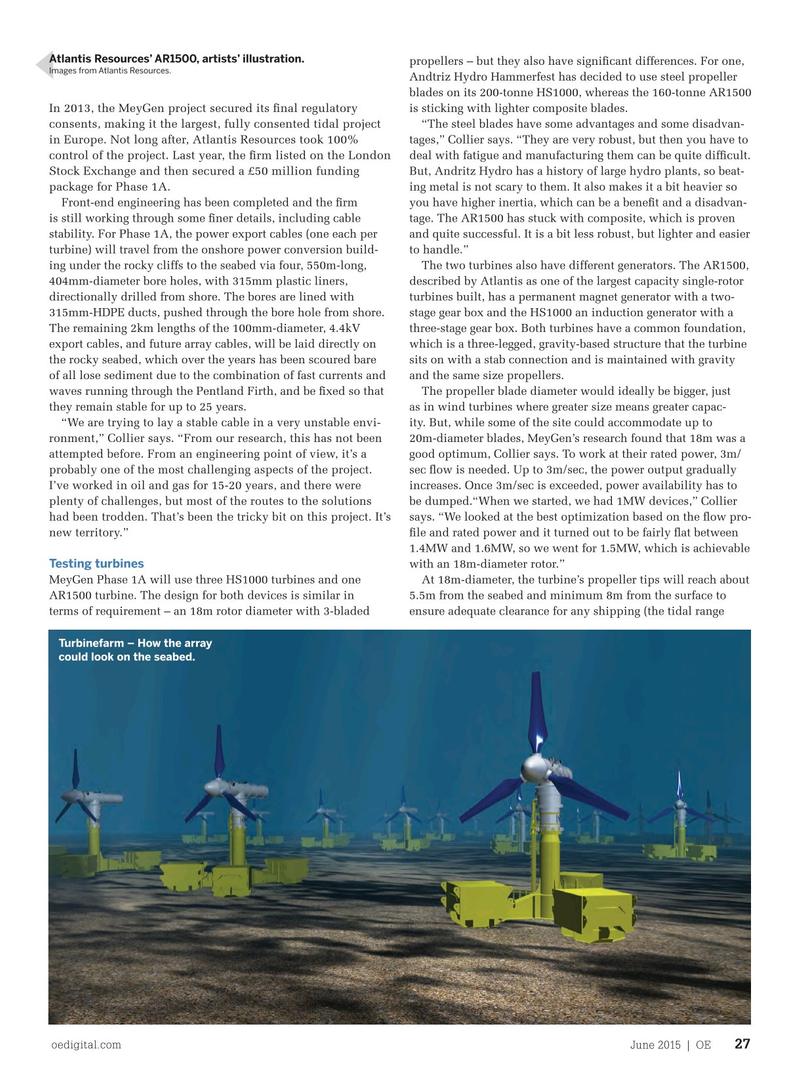

Atlantis Resources’ AR1500, artists’ illustration. propellers – but they also have signifcant differences. For one,

Images from Atlantis Resources.

Andtriz Hydro Hammerfest has decided to use steel propeller blades on its 200-tonne HS1000, whereas the 160-tonne AR1500

In 2013, the MeyGen project secured its fnal regulatory is sticking with lighter composite blades.

consents, making it the largest, fully consented tidal project “The steel blades have some advantages and some disadvan- in Europe. Not long after, Atlantis Resources took 100% tages,” Collier says. “They are very robust, but then you have to control of the project. Last year, the frm listed on the London deal with fatigue and manufacturing them can be quite diffcult.

Stock Exchange and then secured a £50 million funding

But, Andritz Hydro has a history of large hydro plants, so beat- package for Phase 1A. ing metal is not scary to them. It also makes it a bit heavier so

Front-end engineering has been completed and the frm you have higher inertia, which can be a beneft and a disadvan- is still working through some fner details, including cable tage. The AR1500 has stuck with composite, which is proven stability. For Phase 1A, the power export cables (one each per and quite successful. It is a bit less robust, but lighter and easier turbine) will travel from the onshore power conversion build- to handle.” ing under the rocky cliffs to the seabed via four, 550m-long, The two turbines also have different generators. The AR1500, 404mm-diameter bore holes, with 315mm plastic liners, described by Atlantis as one of the largest capacity single-rotor directionally drilled from shore. The bores are lined with turbines built, has a permanent magnet generator with a two- 315mm-HDPE ducts, pushed through the bore hole from shore. stage gear box and the HS1000 an induction generator with a

The remaining 2km lengths of the 100mm-diameter, 4.4kV three-stage gear box. Both turbines have a common foundation, export cables, and future array cables, will be laid directly on which is a three-legged, gravity-based structure that the turbine the rocky seabed, which over the years has been scoured bare sits on with a stab connection and is maintained with gravity of all lose sediment due to the combination of fast currents and and the same size propellers. waves running through the Pentland Firth, and be fxed so that The propeller blade diameter would ideally be bigger, just they remain stable for up to 25 years. as in wind turbines where greater size means greater capac- “We are trying to lay a stable cable in a very unstable envi- ity. But, while some of the site could accommodate up to ronment,” Collier says. “From our research, this has not been 20m-diameter blades, MeyGen’s research found that 18m was a attempted before. From an engineering point of view, it’s a good optimum, Collier says. To work at their rated power, 3m/ probably one of the most challenging aspects of the project. sec fow is needed. Up to 3m/sec, the power output gradually

I’ve worked in oil and gas for 15-20 years, and there were increases. Once 3m/sec is exceeded, power availability has to plenty of challenges, but most of the routes to the solutions be dumped.“When we started, we had 1MW devices,” Collier had been trodden. That’s been the tricky bit on this project. It’s says. “We looked at the best optimization based on the fow pro- new territory.” fle and rated power and it turned out to be fairly fat between 1.4MW and 1.6MW, so we went for 1.5MW, which is achievable

Testing turbines with an 18m-diameter rotor.”

MeyGen Phase 1A will use three HS1000 turbines and one At 18m-diameter, the turbine’s propeller tips will reach about

AR1500 turbine. The design for both devices is similar in 5.5m from the seabed and minimum 8m from the surface to terms of requirement – an 18m rotor diameter with 3-bladed ensure adequate clearance for any shipping (the tidal range

Turbinefarm – How the array could look on the seabed.

A milestone is about to be reached in the tidal energy industry off the cold harsh coast of Scotland. Elaine Maslin talked to the project director behind the

MeyGen tidal array development.

oedigital.com June 2015 | OE 27 026_OE0615_feat1_MayGen.indd 27 6/1/15 10:49 AM

24

24

26

26