Page 40: of Offshore Engineer Magazine (Dec/Jan 2015)

Read this page in Pdf, Flash or Html5 edition of Dec/Jan 2015 Offshore Engineer Magazine

The North Sea

Production Asset of the Month gets steamy team fooding and cyclic steam fooding or cyclic steam injection, known

Using steam to help increase injection have become tried and as the Huff and Puff method, have been oil recovery, particularly from

S tested ways to increase oil recovery onshore. heavy oil, is a well tried and from oil wells, particularly heavy oil or Few, to date have tried to take the in the tar sands where a special variant of technology offshore, with the com- tested technology, but not steam injection known as steam assisted mon assumption being that the density quite so ofshore. Elaine Maslin gravity drainage (SAGD), is used. of wells required and the heat loss as

But, most of the efforts around steam injected steam travels down the well into looks at a bid to change that.

reservoirs would be too great.

However, a UK company is now

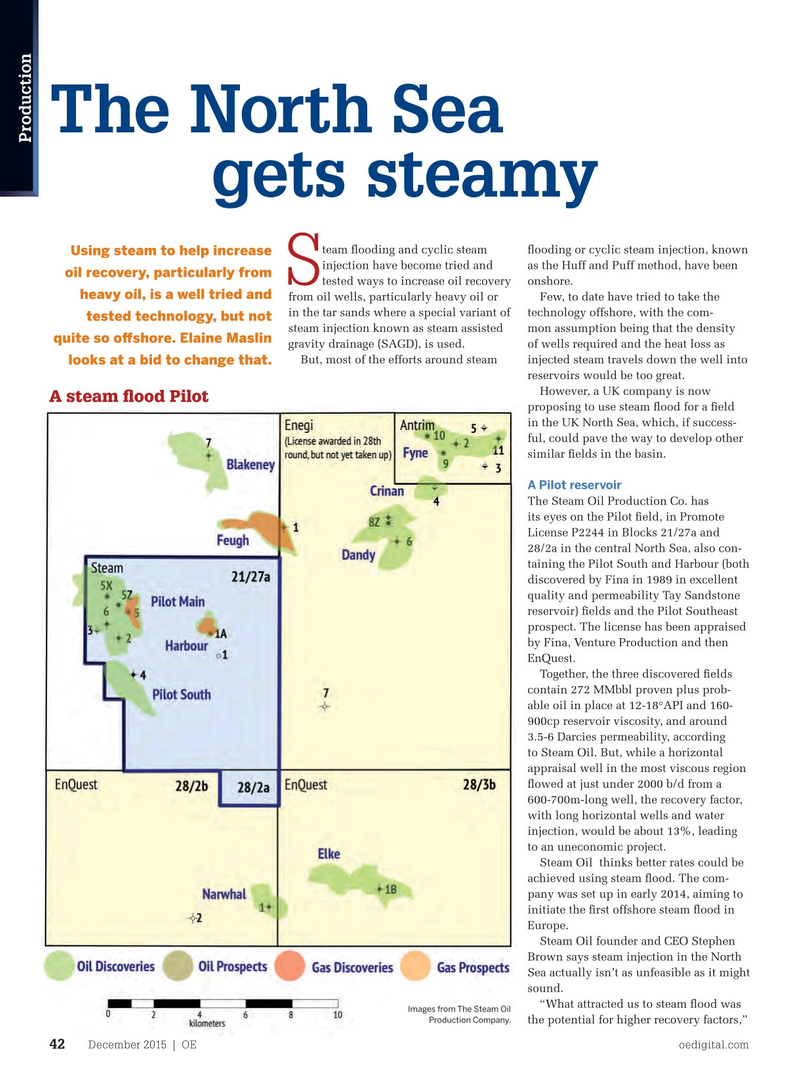

A steam food Pilot proposing to use steam food for a feld in the UK North Sea, which, if success- ful, could pave the way to develop other he says. “Chevron predicts 50-80% similar felds in the basin. [recovery factor using steam food]. Based on modelling, we are looking at around

A Pilot reservoir 60%, achieving about 150 MMbbl

The Steam Oil Production Co. has production from Pilot.” its eyes on the Pilot feld, in Promote

Not so deep concerns

License P2244 in Blocks 21/27a and

One of the key criteria for a 28/2a in the central North Sea, also con- steam food project is depth. taining the Pilot South and Harbour (both

If a reservoir is too shallow, it discovered by Fina in 1989 in excellent could result in steam blowouts, quality and permeability Tay Sandstone but if it is too deep, heat loss in reservoir) felds and the Pilot Southeast the well will reduce the quality prospect. The license has been appraised of the steam too much. Going by Fina, Venture Production and then too deep will also, in combination with

EnQuest. the steam, push the limits of comple-

Together, the three discovered felds tion components, Brown says. As a contain 272 MMbbl proven plus prob- result, typically, the depth limit is given able oil in place at 12-18°API and 160- at around 3000ft, sometimes a little 900cp reservoir viscosity, and around deeper, he says. 3.5-6 Darcies permeability, according to Steam Oil. But, while a horizontal “At 3000ft, typically the reservoir is appraisal well in the most viscous region at 1300psi,” Brown says. “At fowed at just under 2000 b/d from a that pressure the steam tem- 600-700m-long well, the recovery factor, perature will be about 300°C with long horizontal wells and water or 600°F. There are a range of injection, would be about 13%, leading components available at that to an uneconomic project. temperature, but you have to be

Steam Oil thinks better rates could be very careful about selection. If achieved using steam food. The com- you go to 5000ft, we are talking pany was set up in early 2014, aiming to 340°C and you start to run out initiate the frst offshore steam food in of completion components.”

Europe. But, there is some hope here,

Steam Oil founder and CEO Stephen as the industry has been developing com-

Brown says steam injection in the North ponents for use on steam assisted gravity

Sea actually isn’t as unfeasible as it might drainage (SAGD) wells in Alberta and for sound. geothermal wells. “What attracted us to steam food was “When we frst applied for the license

Images from The Steam Oil

Production Company.

the potential for higher recovery factors,” we expected depth to be a big issue,”

December 2015 | OE oedigital.com 42 042_OE1215_ProdOps1_EOR.indd 42 11/20/15 5:43 PM

39

39

41

41