Page 45: of Offshore Engineer Magazine (Dec/Jan 2015)

Read this page in Pdf, Flash or Html5 edition of Dec/Jan 2015 Offshore Engineer Magazine

Subsea Asset of the Month

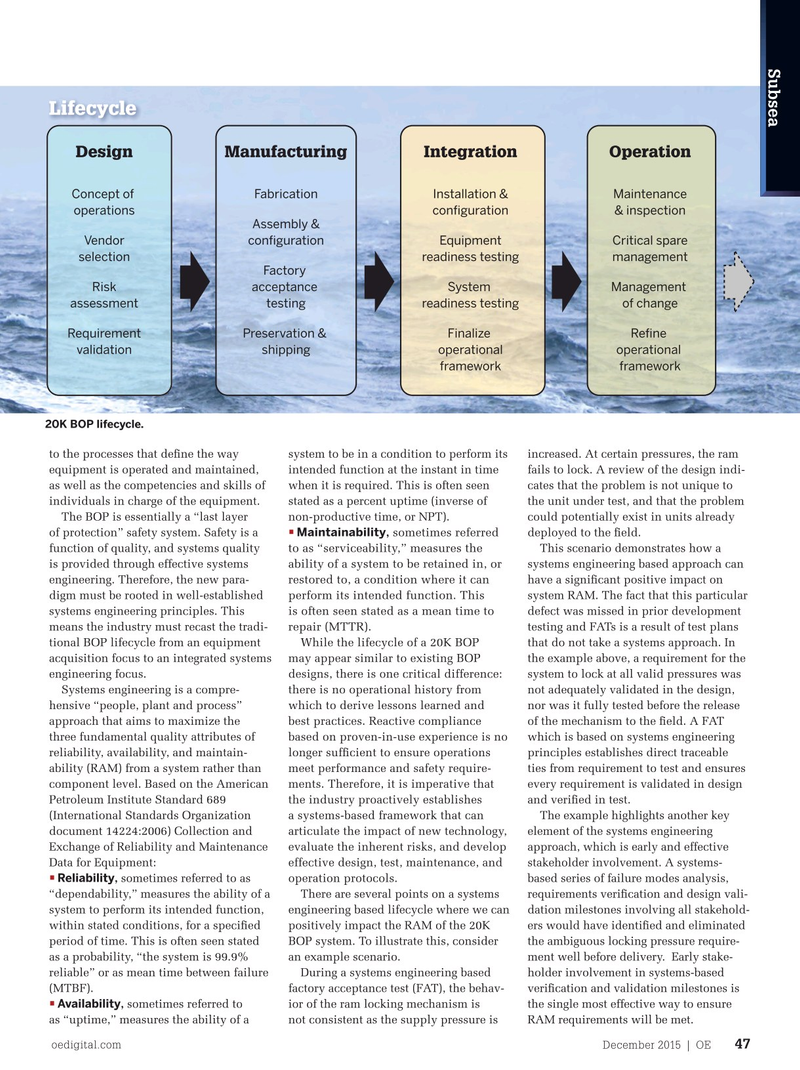

Lifecycle

Design Manufacturing Integration Operation

Concept of Fabrication Installation & Maintenance operations con?guration & inspection

Assembly &

Vendor con?guration Equipment Critical spare selection readiness testing management

Factory

Risk acceptance System Management assessment testing readiness testing of change

Requirement Preservation & Finalize Re?ne validation shipping operational operational framework framework 20K BOP lifecycle.

system to be in a condition to perform its to the processes that de? ne the way increased. At certain pressures, the ram intended function at the instant in time equipment is operated and maintained, fails to lock. A review of the design indi- when it is required. This is often seen as well as the competencies and skills of cates that the problem is not unique to stated as a percent uptime (inverse of individuals in charge of the equipment. the unit under test, and that the problem non-productive time, or NPT). The BOP is essentially a “last layer could potentially exist in units already • Maintainability, sometimes referred of protection” safety system. Safety is a deployed to the ? eld.

to as “serviceability,” measures the function of quality, and systems quality This scenario demonstrates how a ability of a system to be retained in, or is provided through effective systems systems engineering based approach can restored to, a condition where it can engineering. Therefore, the new para- have a signi? cant positive impact on perform its intended function. This digm must be rooted in well-established system RAM. The fact that this particular is often seen stated as a mean time to systems engineering principles. This defect was missed in prior development repair (MTTR).

means the industry must recast the tradi- testing and FATs is a result of test plans

While the lifecycle of a 20K BOP tional BOP lifecycle from an equipment that do not take a systems approach. In may appear similar to existing BOP acquisition focus to an integrated systems the example above, a requirement for the designs, there is one critical difference: engineering focus. system to lock at all valid pressures was there is no operational history from Systems engineering is a compre- not adequately validated in the design, which to derive lessons learned and hensive “people, plant and process” nor was it fully tested before the release best practices. Reactive compliance approach that aims to maximize the of the mechanism to the ? eld. A FAT based on proven-in-use experience is no three fundamental quality attributes of which is based on systems engineering longer suf? cient to ensure operations reliability, availability, and maintain- principles establishes direct traceable meet performance and safety require- ability (RAM) from a system rather than ties from requirement to test and ensures ments. Therefore, it is imperative that component level. Based on the American every requirement is validated in design the industry proactively establishes Petroleum Institute Standard 689 and veri? ed in test.

a systems-based framework that can (International Standards Organization The example highlights another key articulate the impact of new technology, document 14224:2006) Collection and element of the systems engineering evaluate the inherent risks, and develop Exchange of Reliability and Maintenance approach, which is early and effective effective design, test, maintenance, and Data for Equipment: stakeholder involvement. A systems- • operation protocols. Reliability, sometimes referred to as based series of failure modes analysis,

There are several points on a systems “dependability,” measures the ability of a requirements veri? cation and design vali- engineering based lifecycle where we can system to perform its intended function, dation milestones involving all stakehold- positively impact the RAM of the 20K within stated conditions, for a speci? ed ers would have identi? ed and eliminated

BOP system. To illustrate this, consider period of time. This is often seen stated the ambiguous locking pressure require-

Acquisition, operations, and an example scenario. as a probability, “the system is 99.9% ment well before delivery. Early stake- maintenance procedures used on

During a systems engineering based reliable” or as mean time between failure holder involvement in systems-based current generation BOPs may not factory acceptance test (FAT), the behav- (MTBF). veri? cation and validation milestones is be appropriate for 20K BOPs. Photo • ior of the ram locking mechanism is Availability, sometimes referred to the single most effective way to ensure by Daniel Marquez onboard a drillship operating in

Angola.

not consistent as the supply pressure is as “uptime,” measures the ability of a RAM requirements will be met. oedigital.com December 2015 | OE 47 046_OE1215_Subsea1_Athens.indd 47 11/20/15 5:41 PM

44

44

46

46