Page 48: of Offshore Engineer Magazine (Dec/Jan 2015)

Read this page in Pdf, Flash or Html5 edition of Dec/Jan 2015 Offshore Engineer Magazine

desired properties.

OE: How does Smart Corrosion Detector bead work?

If you have a surface (aluminum) that starts corroding, trivalent ions (tri-

Getting smart

Pipelines aluminum) begin to form. These ions interact with the outside of the capsule and form a complex that causes the capsule to stretch to the point of break- about corrosion age. The healing agent, a thermoplastic oligomer, fows out of the capsule and are not damaged when mixing within

Jerry Lee speaks with Olga flls the crack that formed during corro- the paint or coating; and there needs to

Koper, business lead for Energy sion. In addition, the complex fuoresces be the right amount of capillary action at Battelle, to fnd out more when exposed to UV light. So, not only to ensure the active material fows out is the crack healed, but you’re able to when the capsule is broken and flls the about the company’s corrosion see where the crack occur because it will crack. resistant coating, which seeks

These are interesting problems be able to fuoresce.

OE: How is this a “smart” technology?

because there are so many variables to “heal” cracks in pipelines.

It is smart because the trigger is the that you have to get just right to get the corrosion by-product reacting with the attling corrosion is a constant shell of the capsule, stressing it to the struggle in the offshore environ- point of breaking. The Smart Corrosion

B ment, and effective inspection is

Detector bead mitigates corrosion and made more diffcult when the problems provides a visual indication, offering a are too small to see. Addressing these multifunctional type of material that act issues, Battelle has developed a corrosion when and where you want the action to resistant coating using novel self-healing occur.

OE: What applications are there for this oligomer flled microcapsules, the Smart technology?

Corrosion Detector bead. The function of

This technology is focused on metals this technology is to “heal” cracks caused surfaces that are prone to corrosion. by corrosion and indicate the location of

Since we are incorporating it into the issue.

OE: What is the technology behind the paints and coating, anywhere you can

Smart Corrosion Detector bead?

use coatings or paints you can add the

You have a capsule capsules to have the self-healing appli- that is flled with cation working. For offshore applica- an active mate- tions, we envision that it may have rial, which is then applications on pipelines, hardware, and equipment.

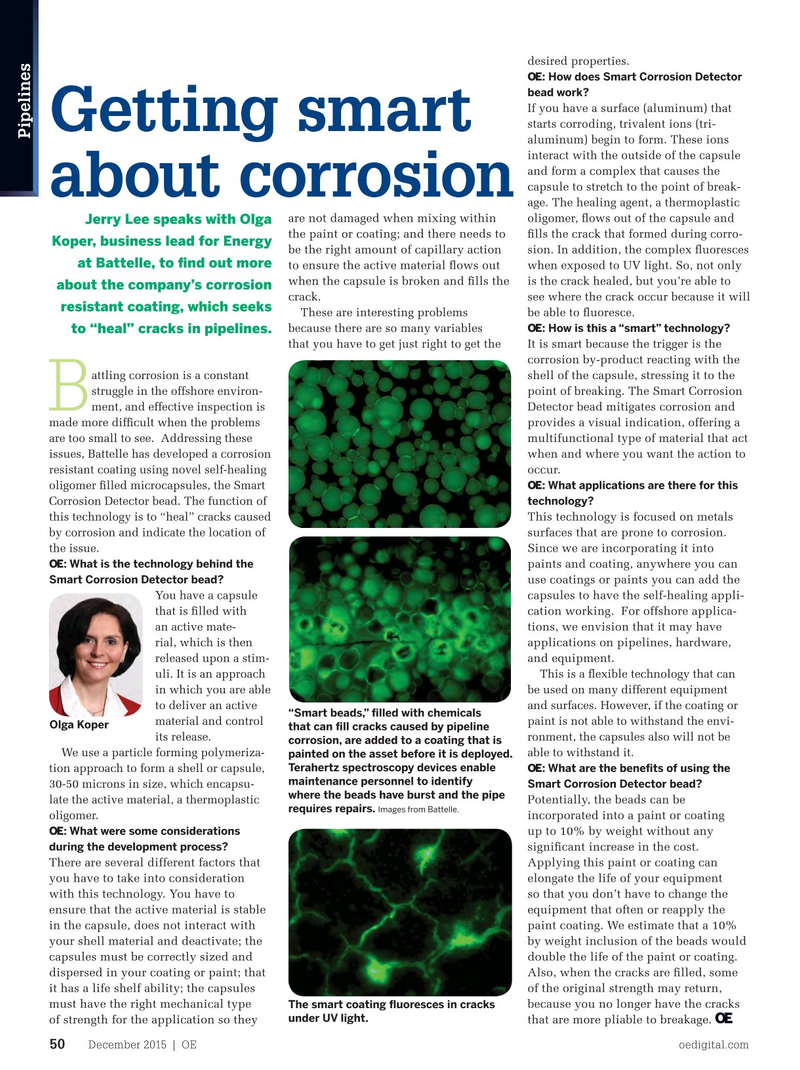

released upon a stim- uli. It is an approach This is a fexible technology that can in which you are able be used on many different equipment to deliver an active and surfaces. However, if the coating or “Smart beads,” flled with chemicals material and control paint is not able to withstand the envi-

Olga Koper that can fll cracks caused by pipeline its release. ronment, the capsules also will not be corrosion, are added to a coating that is

We use a particle forming polymeriza- able to withstand it.

painted on the asset before it is deployed.

Terahertz spectroscopy devices enable OE: What are the benefts of using the tion approach to form a shell or capsule, maintenance personnel to identify

Smart Corrosion Detector bead?

30-50 microns in size, which encapsu- where the beads have burst and the pipe

Potentially, the beads can be late the active material, a thermoplastic

Images from Battelle.

requires repairs. incorporated into a paint or coating oligomer.

OE: What were some considerations up to 10% by weight without any during the development process?

signifcant increase in the cost.

There are several different factors that Applying this paint or coating can you have to take into consideration elongate the life of your equipment with this technology. You have to so that you don’t have to change the ensure that the active material is stable equipment that often or reapply the in the capsule, does not interact with paint coating. We estimate that a 10% your shell material and deactivate; the by weight inclusion of the beads would capsules must be correctly sized and double the life of the paint or coating. dispersed in your coating or paint; that Also, when the cracks are flled, some it has a life shelf ability; the capsules of the original strength may return, must have the right mechanical type because you no longer have the cracks

The smart coating fuoresces in cracks under UV light.

of strength for the application so they that are more pliable to breakage.

December 2015 | OE oedigital.com 50 000_OE1215_Pipelines1_Batelle.indd 50 11/20/15 5:38 PM

47

47

49

49