Page 36: of Offshore Engineer Magazine (Mar/Apr 2017)

Read this page in Pdf, Flash or Html5 edition of Mar/Apr 2017 Offshore Engineer Magazine

? eld performance indicators; alarms and worrying about changing monitoring First, is the digital era of arti? cial events management; and diagnostics platforms. lift. The progression of arti? cial lift is and optimization. In the market today, we are starting twofold: the advancement of equipment to see operators in the shale plays move functionality running in parallel with

Nathan Holland, to gas lift earlier on gathering and inter- product line in the cycle, in part preting data metrics director, because of advances for well optimization.

PRODUCTION

Arti? cial Lift in gas-lift technology. Adding sensors and

Systems, Baker These new technolo- measurements is the

Hughes: Baker gies reduce capital ? rst step to run-life

Hughes recently equipment expenses improvements; how- launched the and increase cost ever, analyzing and

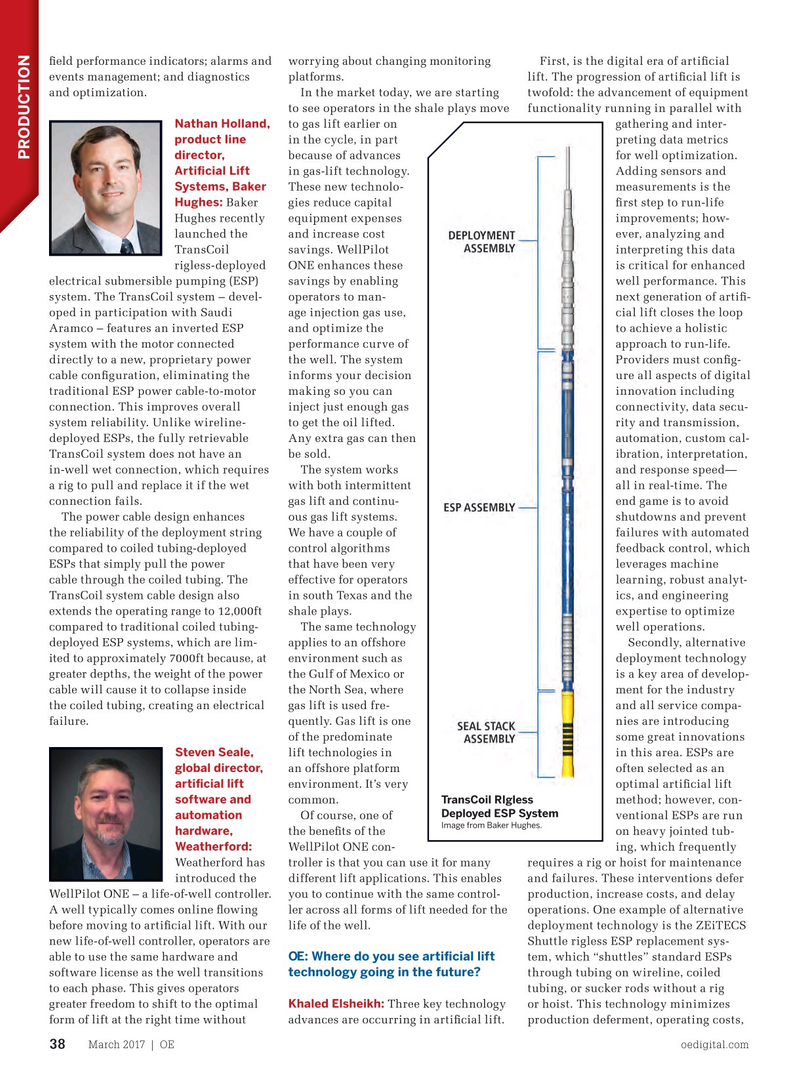

TransCoil savings. WellPilot interpreting this data rigless-deployed ONE enhances these is critical for enhanced electrical submersible pumping (ESP) savings by enabling well performance. This system. The TransCoil system – devel- operators to man- next generation of arti? - oped in participation with Saudi age injection gas use, cial lift closes the loop

Aramco – features an inverted ESP and optimize the to achieve a holistic system with the motor connected performance curve of approach to run-life. directly to a new, proprietary power the well. The system Providers must con? g- cable con? guration, eliminating the informs your decision ure all aspects of digital traditional ESP power cable-to-motor making so you can innovation including connection. This improves overall inject just enough gas connectivity, data secu- system reliability. Unlike wireline- to get the oil lifted. rity and transmission, deployed ESPs, the fully retrievable Any extra gas can then automation, custom cal-

TransCoil system does not have an be sold. ibration, interpretation, in-well wet connection, which requires The system works and response speed— a rig to pull and replace it if the wet with both intermittent all in real-time. The connection fails. gas lift and continu- end game is to avoid

The power cable design enhances ous gas lift systems. shutdowns and prevent the reliability of the deployment string We have a couple of failures with automated compared to coiled tubing-deployed control algorithms feedback control, which

ESPs that simply pull the power that have been very leverages machine cable through the coiled tubing. The effective for operators learning, robust analyt-

TransCoil system cable design also in south Texas and the ics, and engineering extends the operating range to 12,000ft shale plays. expertise to optimize compared to traditional coiled tubing- The same technology well operations. deployed ESP systems, which are lim- applies to an offshore Secondly, alternative ited to approximately 7000ft because, at environment such as deployment technology greater depths, the weight of the power the Gulf of Mexico or is a key area of develop- cable will cause it to collapse inside the North Sea, where ment for the industry the coiled tubing, creating an electrical gas lift is used fre- and all service compa- failure. quently. Gas lift is one nies are introducing of the predominate some great innovations

Steven Seale, lift technologies in in this area. ESPs are global director, an offshore platform often selected as an arti? cial lift environment. It’s very optimal arti? cial lift software and common. method; however, con-

TransCoil RIgless

Deployed ESP System automation Of course, one of ventional ESPs are run

Image from Baker Hughes.

hardware, the bene? ts of the on heavy jointed tub-

Weatherford: WellPilot ONE con- ing, which frequently

Weatherford has troller is that you can use it for many requires a rig or hoist for maintenance introduced the different lift applications. This enables and failures. These interventions defer

WellPilot ONE – a life-of-well controller. you to continue with the same control- production, increase costs, and delay

A well typically comes online ? owing ler across all forms of lift needed for the operations. One example of alternative before moving to arti? cial lift. With our life of the well. deployment technology is the ZEiTECS new life-of-well controller, operators are Shuttle rigless ESP replacement sys-

OE: Where do you see arti? cial lift able to use the same hardware and tem, which “shuttles” standard ESPs technology going in the future?

software license as the well transitions through tubing on wireline, coiled to each phase. This gives operators tubing, or sucker rods without a rig greater freedom to shift to the optimal Khaled Elsheikh: Three key technology or hoist. This technology minimizes form of lift at the right time without advances are occurring in arti? cial lift. production deferment, operating costs,

March 2017 | OE oedigital.com 38 037_OE0217_Prod1_Audrey.indd 38 2/21/17 7:14 PM

35

35

37

37