Page 56: of Offshore Engineer Magazine (Jul/Aug 2019)

Subsea Processing

Read this page in Pdf, Flash or Html5 edition of Jul/Aug 2019 Offshore Engineer Magazine

TECH FILES NDT

Radiography for NDT

By Jennifer Pallanich technology used in security and drug enforcement thinks it’s seeing the radiation from its own isotope. It con- was modi? ed to solve the age-old problem of how fuses it, and it thinks there’s been a major production process to use radiography for nondestructive testing of issue and even shutdown of production. It’s a false alarm,”

A pipelines on rigs without affecting nucleonic mea- that often leads the control room to shut the rig down, he says.

surement associated with pressure vessels. Oceaneering worked with manufacturers of specialist

The adapted technology doesn’t skew nucleonics on high- “pulsed” x-ray systems and nucleonic instrumentation to pressure vessels such as oil-gas-water separators or force a design a procedure that makes it possible to carry out NDT shutdown, and it’s allowing operators in the North Sea to rap- inspections while the plant is in-service by eliminating the ef- idly carry out deferred pipeline inspections without waiting fects of radiography operations on nucleonics. Oceaneering for a planned turnaround or shutdown. calls the offering Trip Avoidance X-ray Inspection (TAXI).

In an industry with aging infrastructure, nondestructive test- TAXI uses an x-ray camera that uses short radiation pulses ing (NDT) is vital for determining whether a material or com- rather than a constant source of radiation, typical of radio iso- ponent remains ? t for purpose. Radiography has long been tope. “The nucleonic detector can’t see the short bursts, but we used to seek corrosion, cracks and other problems in equip- still get good x-ray images of the process piping and equip- ment like pipelines, particularly those that are insulated. But ment,” McNab says.

sometimes NDT methods like radiography interfere with oth- Ahead of an inspection, McNab says, the inspection team er nucleonic instrumentation and sensing programs. reviews sources of data that may in? uence what effect TAXI

Nucleonic sensors are used on the high-pressure units that will have on the existing nucleonics.

separate the production stream into oil, gas and water because Oceaneering has deployed TAXI in the North Sea over the such vessels can present a safety issue if they become too full course of the last year. One operator had planned pipeline in- or too empty. A nucleonic detector on one side of the vessel tegrity inspections over the course of three years to coincide can sense an isotope on the other side. As the ? uid level within with shutdowns. Oceaneering’s TAXI service was able to car- the separator falls, the detector can sense the radiation from ry out the inspections while the plant was in continuous pro- the other side, while a rising level of ? uid blocks the signal. duction in three weeks without requiring a shutdown, he says.

When radiography is used, there is a high risk the radiation “What we’re doing now is enabling operators to inspect pip- can “confuse” the nucleonic detector, says Jim McNab, NDT ing and equipment they wouldn’t have been able to do pre- subject matter expert at Oceaneering. “When the nucleonic viously, during production operations,” McNab says. “In es- detector sees the radiation from an exposed NDT isotope, it sence, we’re able to ? nd the leaks before leaks ? nd us.”

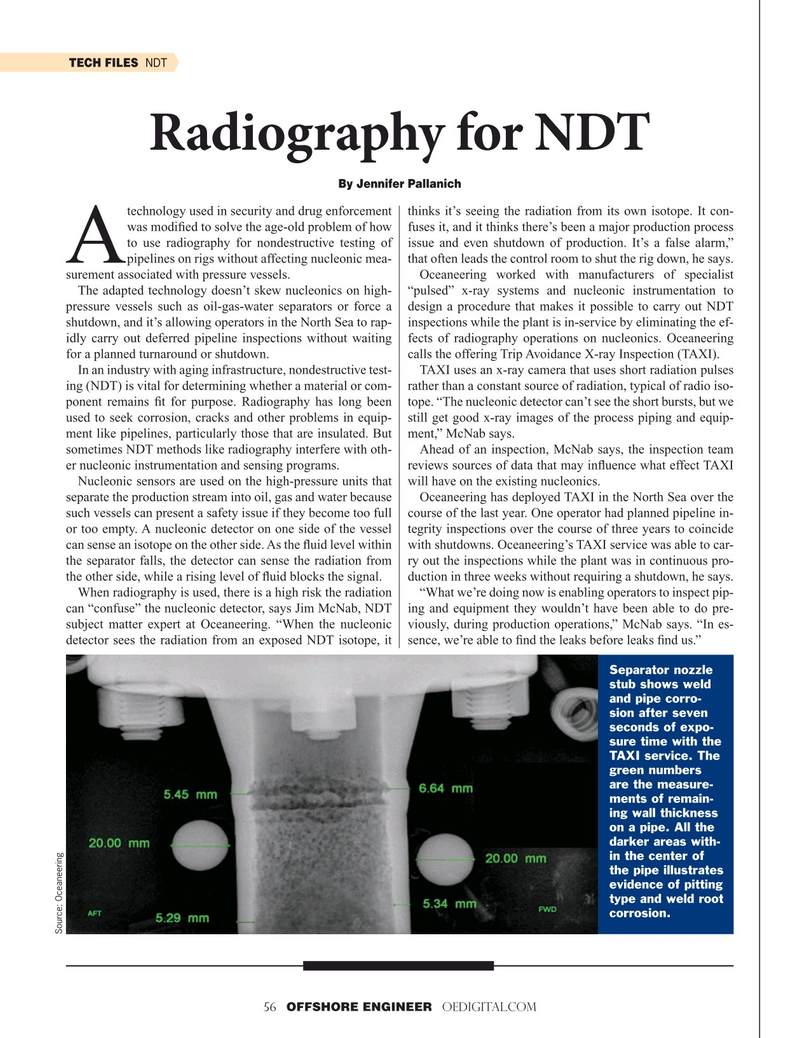

Separator nozzle stub shows weld and pipe corro- sion after seven seconds of expo- sure time with the

TAXI service. The green numbers are the measure- ments of remain- ing wall thickness on a pipe. All the darker areas with- in the center of the pipe illustrates evidence of pitting type and weld root corrosion.

Source: Oceaneering 56 OFFSHORE ENGINEER OEDIGITAL.COM

55

55

57

57