Page 55: of Offshore Engineer Magazine (Jan/Feb 2020)

Read this page in Pdf, Flash or Html5 edition of Jan/Feb 2020 Offshore Engineer Magazine

many iterations and updates as the industry innovated into capsulates the gas. The resin gives the cement time to cure.

ever deeper waters. PAES helps with concept selection and “Resins can be a great option, especially for downers or assessing multiple removal scenarios. bubblers.” “We have about 30 years of data and various methodolo- Downers are structures or wells that were damaged due gies,” Boudoin says. to age, impact or storm effects. Bubblers are abandoned

Being able to plan contingencies makes it possible to wells that develop a containment leak, allowing gas to bub- minimize cost escalations. ble from the abandoned well.

“Surprises are when the costs explode,” Speck says.

TIME FOR GROWTH

He recalls one project where executing an abrasive cut on

Speck, who holds a mechanical engineering degree and a piling took three times longer than expected because the is a licensed professional engineer, has worked in ? eld op- wall thickness was much greater than records indicated.

erations, project management and operations management “It was like the difference between a hollow Easter bun- with Schlumberger, GE Wellstream and TSB Offshore. He ny and a solid one,” Boudoin says.

Speck believes abrasive cutting will continue to expand was previously TSB Offshore’s director of operations.

“We’re looking to expand our services, especially over- as a choice technology instead of explosives. Diamond wire is becoming more ef? cient with smaller pro? les, and it can seas,” Speck says. In 2019, about a third of the company’s be run via remotely operated vehicle (ROV) to remove work was overseas.

One of the areas of growth that excites Speck is the abil- portions of a structure.

ity to assist countries and regulatory bodies codify regu-

On the cementing side, he says, resins are gaining accep- lations and processes. The company conducts decommis- tance for well plug and abandonments. In places where ce- ment is setting, any slow gas bubbles will channel through sioning workshops around the world, and aims to grow its land-based decommissioning activities for LNG facilities, that cement, which means there is no real barrier for pres- sure containment. But, he says, by topping the cement with production facilities, land assets and ? elds.

“We’re focusing on being lean and ef? cient,” Speck says.

resin, even if gas bubbles through the cement, the resin en-

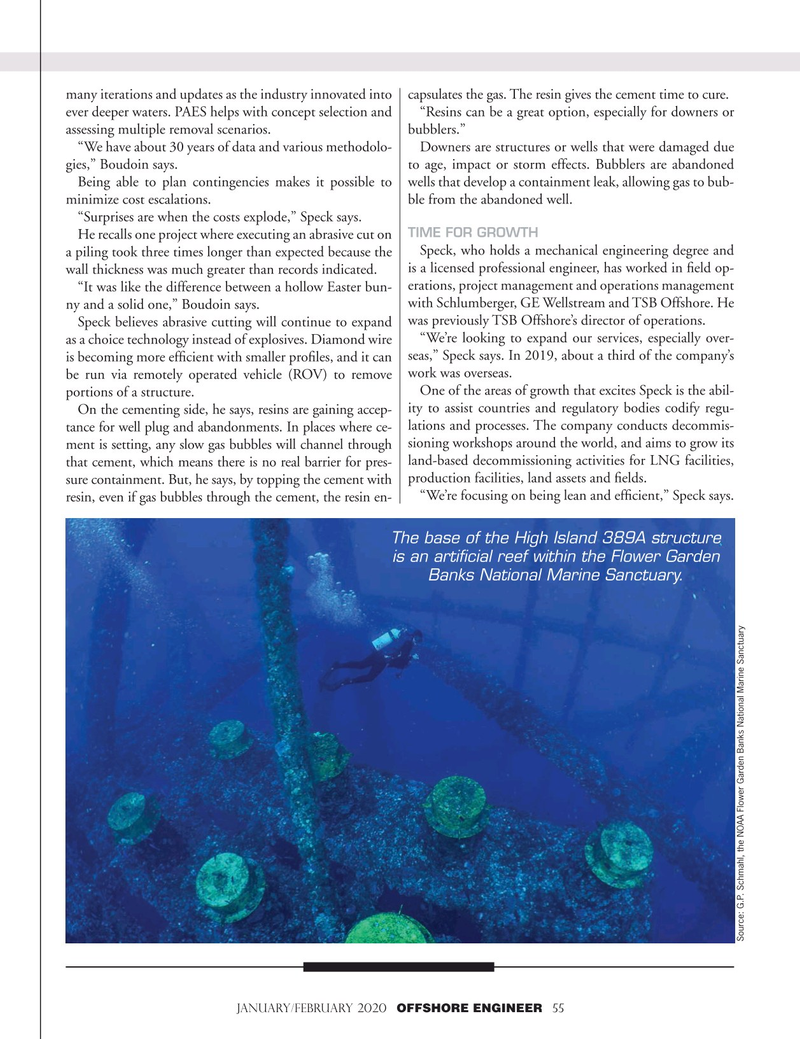

The base of the High Island 389A structure is an artificial reef within the Flower Garden

Banks National Marine Sanctuary.

Source: G.P. Schmahl, the NOAA Flower Garden Banks National Marine Sanctuary jANUARY/FEBRUARY 2020 OFFSHORE ENGINEER 55

54

54

56

56