Page 28: of Offshore Engineer Magazine (May/Jun 2020)

Read this page in Pdf, Flash or Html5 edition of May/Jun 2020 Offshore Engineer Magazine

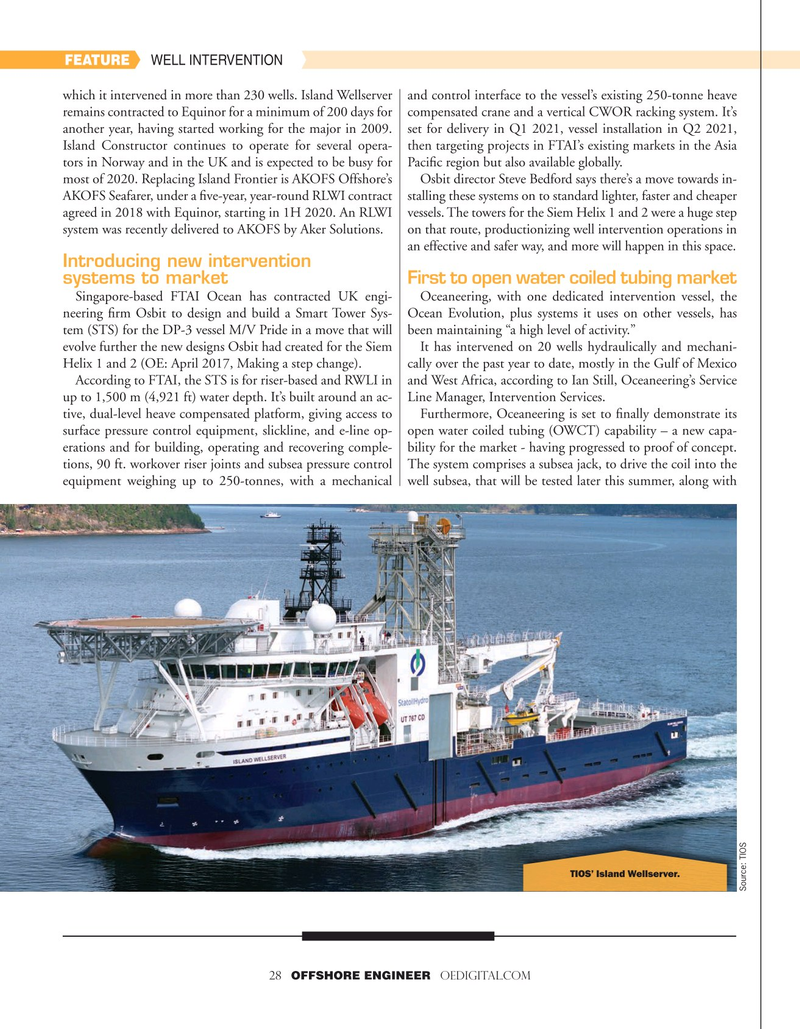

FEATURE WELL INTERVENTION which it intervened in more than 230 wells. Island Wellserver and control interface to the vessel’s existing 250-tonne heave remains contracted to Equinor for a minimum of 200 days for compensated crane and a vertical CWOR racking system. It’s another year, having started working for the major in 2009. set for delivery in Q1 2021, vessel installation in Q2 2021,

Island Constructor continues to operate for several opera- then targeting projects in FTAI’s existing markets in the Asia tors in Norway and in the UK and is expected to be busy for Pacifc region but also available globally. most of 2020. Replacing Island Frontier is AKOFS Offshore’s Osbit director Steve Bedford says there’s a move towards in-

AKOFS Seafarer, under a fve-year, year-round RLWI contract stalling these systems on to standard lighter, faster and cheaper agreed in 2018 with Equinor, starting in 1H 2020. An RLWI vessels. The towers for the Siem Helix 1 and 2 were a huge step system was recently delivered to AKOFS by Aker Solutions. on that route, productionizing well intervention operations in an effective and safer way, and more will happen in this space.

Introducing new intervention systems to market First to open water coiled tubing market

Singapore-based FTAI Ocean has contracted UK engi- Oceaneering, with one dedicated intervention vessel, the neering frm Osbit to design and build a Smart Tower Sys- Ocean Evolution, plus systems it uses on other vessels, has tem (STS) for the DP-3 vessel M/V Pride in a move that will been maintaining “a high level of activity.” evolve further the new designs Osbit had created for the Siem It has intervened on 20 wells hydraulically and mechani-

Helix 1 and 2 (OE: April 2017, Making a step change). cally over the past year to date, mostly in the Gulf of Mexico

According to FTAI, the STS is for riser-based and RWLI in and West Africa, according to Ian Still, Oceaneering’s Service up to 1,500 m (4,921 ft) water depth. It’s built around an ac- Line Manager, Intervention Services. tive, dual-level heave compensated platform, giving access to Furthermore, Oceaneering is set to fnally demonstrate its surface pressure control equipment, slickline, and e-line op- open water coiled tubing (OWCT) capability – a new capa- erations and for building, operating and recovering comple- bility for the market - having progressed to proof of concept. tions, 90 ft. workover riser joints and subsea pressure control The system comprises a subsea jack, to drive the coil into the equipment weighing up to 250-tonnes, with a mechanical well subsea, that will be tested later this summer, along with

TIOS’ Island Wellserver.

Source: TIOS 28 OFFSHORE ENGINEER OEDIGITAL.COM

27

27

29

29