Page 20: of Offshore Engineer Magazine (Jan/Feb 2021)

Floating Production Outlook

Read this page in Pdf, Flash or Html5 edition of Jan/Feb 2021 Offshore Engineer Magazine

FEATURE FPSOs

OVID-19 will continue to skew the ?oating produc- ing plants; some are mega units capable of processing 250,000 tion systems market for the coming 24 months, while b/d. While most are ship-shaped, a few have cylindrical hulls. buying power for a large portion of FPSO contracts Some are ?tted with external or internal turrets to weather-

C will be centered in Brazil and Guyana/Suriname. vane; others are spread-moored.

These two areas are expected to account for more than 60% of Some are designed to permanently remain on ?eld, some to the FPSO contracts awarded between 2021 and 2025. be quickly disconnected.

These are the ?ndings shared in a recent ?oating produc- The cost of building an FPSO ranges from $200 million tion outlook report produced by International Maritime As- to $3 billion, depending on production plant capacity, design sociates (IMA) and World Energy Reports (WER). life, local content requirement, operating environment, and

The 100+ page report examines business conditions likely other factors. to drive investment decisions in deepwater development over FPSOs have a number of important advantages over other the next ?ve years and forecasts the number and timing of production systems. The most important is their ?eld stor- orders for ?oating production systems through 2025. age capability, which allows production in locations economi- cally inaccessible to pipeline infrastructure. Among other ad-

FPSO Overview vantages: water depth is not a constrain, they can operate in

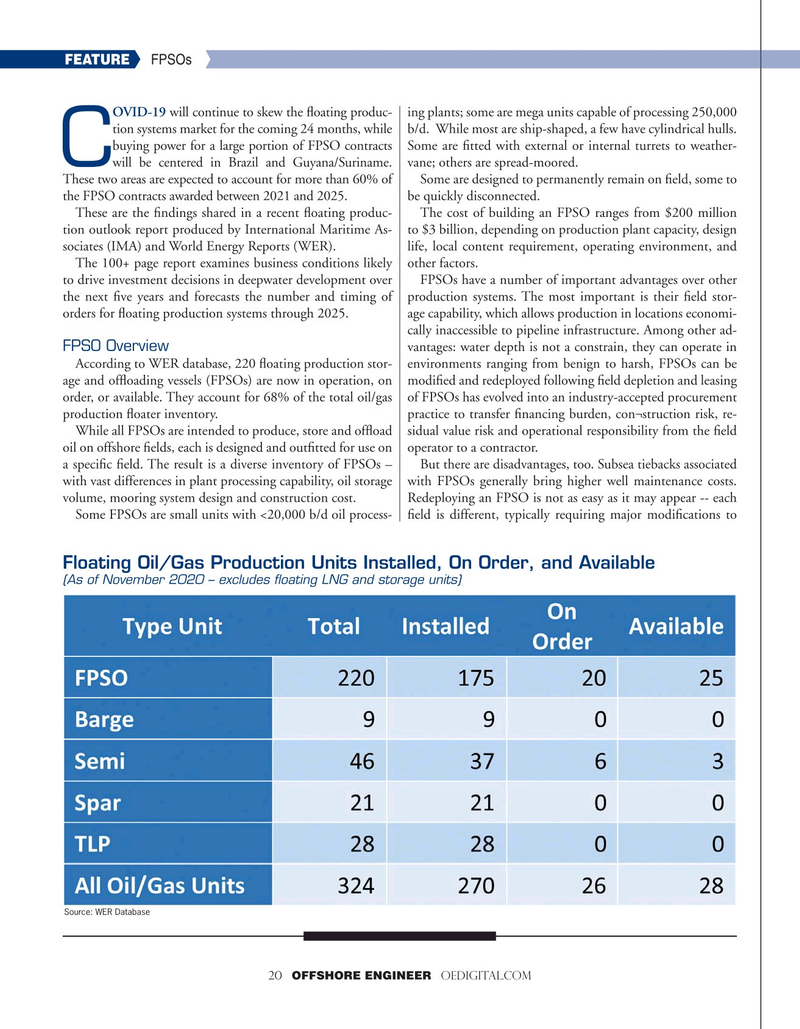

According to WER database, 220 ?oating production stor- environments ranging from benign to harsh, FPSOs can be age and of?oading vessels (FPSOs) are now in operation, on modi?ed and redeployed following ?eld depletion and leasing order, or available. They account for 68% of the total oil/gas of FPSOs has evolved into an industry-accepted procurement production ?oater inventory. practice to transfer ?nancing burden, con¬struction risk, re-

While all FPSOs are intended to produce, store and of?oad sidual value risk and operational responsibility from the ?eld oil on offshore ?elds, each is designed and out?tted for use on operator to a contractor. a speci?c ?eld. The result is a diverse inventory of FPSOs – But there are disadvantages, too. Subsea tiebacks associated with vast differences in plant processing capability, oil storage with FPSOs generally bring higher well maintenance costs. volume, mooring system design and construction cost. Redeploying an FPSO is not as easy as it may appear -- each

Some FPSOs are small units with <20,000 b/d oil process- ?eld is different, typically requiring major modi?cations to

Floating Oil/Gas Production Units Installed, On Order, and Available (As of November 2020 – excludes floating LNG and storage units)

Source: WER Database 20 OFFSHORE ENGINEER OEDIGITAL.COM

19

19

21

21