Page 36: of Offshore Engineer Magazine (Jan/Feb 2021)

Floating Production Outlook

Read this page in Pdf, Flash or Html5 edition of Jan/Feb 2021 Offshore Engineer Magazine

FEATURE DRILLING & COMPLETIONS

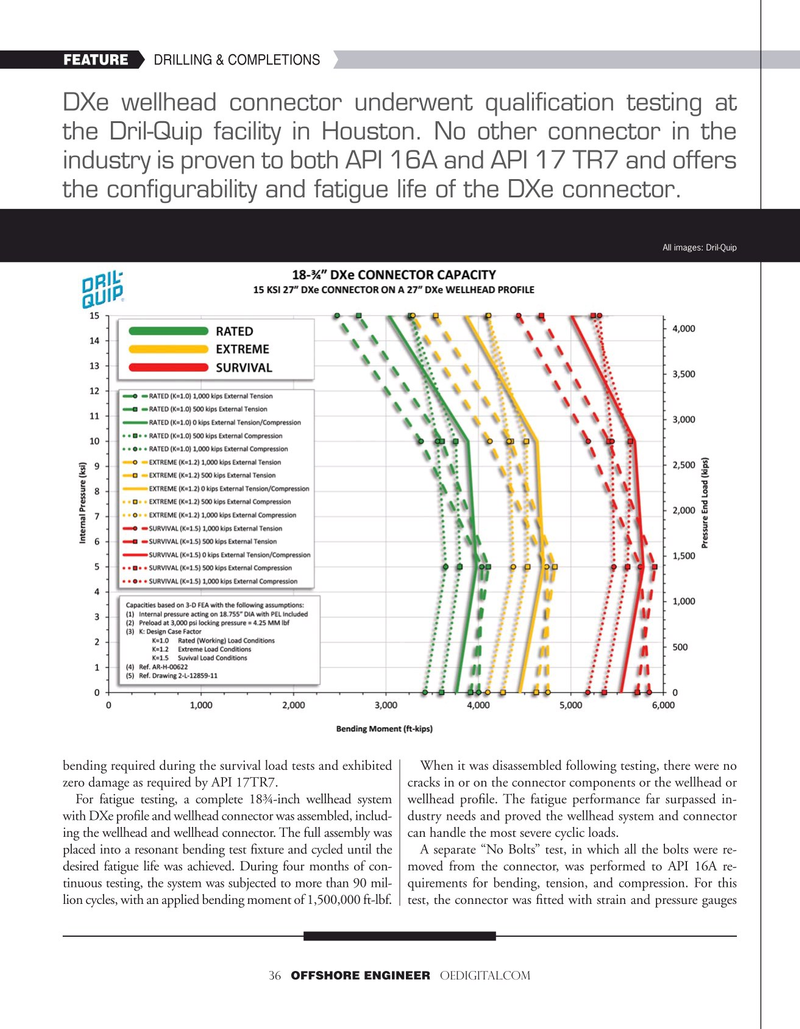

DXe wellhead connector underwent qualification testing at the Dril-Quip facility in Houston. No other connector in the industry is proven to both API 16A and API 17 TR7 and offers the configurability and fatigue life of the DXe connector.

All images: Dril-Quip bending required during the survival load tests and exhibited When it was disassembled following testing, there were no zero damage as required by API 17TR7. cracks in or on the connector components or the wellhead or

For fatigue testing, a complete 18¾-inch wellhead system wellhead pro?le. The fatigue performance far surpassed in- with DXe pro?le and wellhead connector was assembled, includ- dustry needs and proved the wellhead system and connector ing the wellhead and wellhead connector. The full assembly was can handle the most severe cyclic loads. placed into a resonant bending test ?xture and cycled until the A separate “No Bolts” test, in which all the bolts were re- desired fatigue life was achieved. During four months of con- moved from the connector, was performed to API 16A re- tinuous testing, the system was subjected to more than 90 mil- quirements for bending, tension, and compression. For this lion cycles, with an applied bending moment of 1,500,000 ft-lbf. test, the connector was ?tted with strain and pressure gauges 36 OFFSHORE ENGINEER OEDIGITAL.COM

35

35

37

37