Page 19: of Offshore Engineer Magazine (Sep/Oct 2021)

Digital Transformation

Read this page in Pdf, Flash or Html5 edition of Sep/Oct 2021 Offshore Engineer Magazine

Reliability and management of key production assets con- tinue to be an area of critical focus – unplanned maintenance on a foating production facility costs an estimated 100 times the amount of the onshore equivalent. Assets are operated to production limits. Maintenance equipment and expertise are often lacking onboard, which necessitates the high costs and inconvenience of transporting equipment and personnel to remote locations. Plus, the turnover rate for operations staff is higher than average. New personnel must be trained special- ists with qualifed experience to be effective and follow crucial safety measures. All these issues negatively impact equipment life and increase operations and maintenance costs.

Meanwhile, Health, Safety, Security and Environment (HSSE) is another major challenge. An overriding and un- deniable goal of the industry is to decrease and eliminate in- cidents, whether they’re related to safety, spills (hydrocarbon containment), cyber security or something else.

For example, the number of ransomware incidents involv- ing the manufacturing sector increased 156% between the frst quarters of 2019 and 2020. In addition, recently several manufacturing organizations were targeted with cybersecurity threats, including one of the largest U.S. pipeline operators,

Colonial Pipeline. In May, the operator shut down 5,500 miles of pipeline, which carries 45% of the East Coast’s fuel supplies, to contain a ransomware breach.

To help with these challenges, oil and gas companies need to implement industry-proven standards such as NIST and

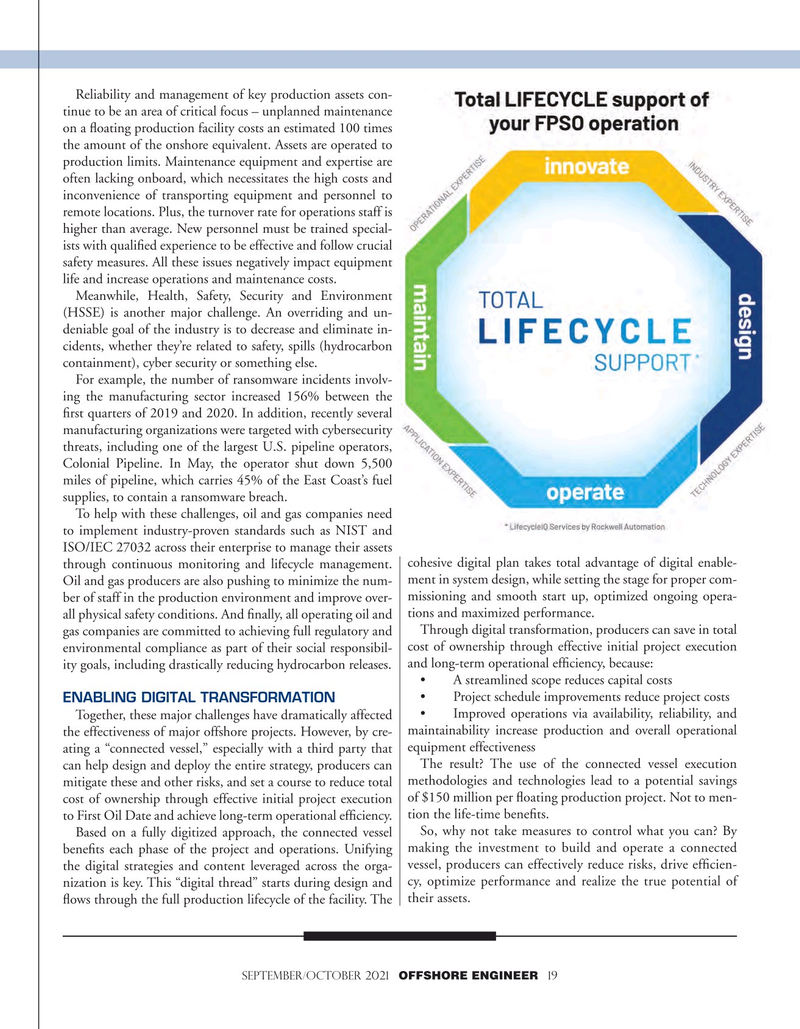

ISO/IEC 27032 across their enterprise to manage their assets through continuous monitoring and lifecycle management. cohesive digital plan takes total advantage of digital enable- ment in system design, while setting the stage for proper com-

Oil and gas producers are also pushing to minimize the num- missioning and smooth start up, optimized ongoing opera- ber of staff in the production environment and improve over- all physical safety conditions. And fnally, all operating oil and tions and maximized performance.

Through digital transformation, producers can save in total gas companies are committed to achieving full regulatory and cost of ownership through effective initial project execution environmental compliance as part of their social responsibil- and long-term operational effciency, because: ity goals, including drastically reducing hydrocarbon releases.

• A streamlined scope reduces capital costs • Project schedule improvements reduce project costs

ENABLING DIGITAL TRANSFORMATION • Improved operations via availability, reliability, and

Together, these major challenges have dramatically affected maintainability increase production and overall operational the effectiveness of major offshore projects. However, by cre- ating a “connected vessel,” especially with a third party that equipment effectiveness

The result? The use of the connected vessel execution can help design and deploy the entire strategy, producers can mitigate these and other risks, and set a course to reduce total methodologies and technologies lead to a potential savings cost of ownership through effective initial project execution of $150 million per foating production project. Not to men- to First Oil Date and achieve long-term operational effciency. tion the life-time benefts.

So, why not take measures to control what you can? By

Based on a fully digitized approach, the connected vessel benefts each phase of the project and operations. Unifying making the investment to build and operate a connected vessel, producers can effectively reduce risks, drive effcien- the digital strategies and content leveraged across the orga- nization is key. This “digital thread” starts during design and cy, optimize performance and realize the true potential of fows through the full production lifecycle of the facility. The their assets. september/october 2021 OFFSHORE ENGINEER 19

18

18

20

20