Page 41: of Offshore Engineer Magazine (Jan/Feb 2024)

Read this page in Pdf, Flash or Html5 edition of Jan/Feb 2024 Offshore Engineer Magazine

Also, the company installed variable frequency drives The classifcation serves as a testament to Stena Drill- (VFDs) for its high load marine cooling pumps, which ing’s rigorous monitoring of energy consumption and the resulted in the reduction of annual emissions by 1800 implementation of both operational and technical mea- (te) along with a boost accumulator for the hydraulic sures to notably reduce emissions.

ringline system which contributed further 1,300 (te) to “The blue-chip companies that we’re working with are the overall result. very interested in what we’re doing to cut fuel consump- “We have also commissioned a feasibility study on the use tion and lower our emissions.

of alternative fuels. The alternatives were green methanol and “We’re also seeing co-investment with our clients into fuel ammonia. A detailed report has been received and this is now saving technology and exploring alternative fuels. For new being studied by our engineering team,” Rønsberg pointed tenders, there is usually a question about environmental per- out, noting also the company is exploring the use of ‘synthet- formance, but so far usually not prescriptive requirements.

ic diesel’ produced variety of vegetable and animal sources “The most modern rigs are often best, but our Drill- which could reduce CO2 emissions by as much as 90%. MAX class units with the hydraulic lifting systems still ap- “HVO can be used as an additive without any modifca- pear to be very effcient when we’ve had the opportunity to tion to engines and the CO2 reduction is almost equal to measure against our peers.

the percentage of HVO used, i.e., 10% HVO in supply ˜ “I want to future proof as much as possible, so that’s 9% reduction in CO2 emissions,” said Rønsberg. a key driver in continued investment in environmental

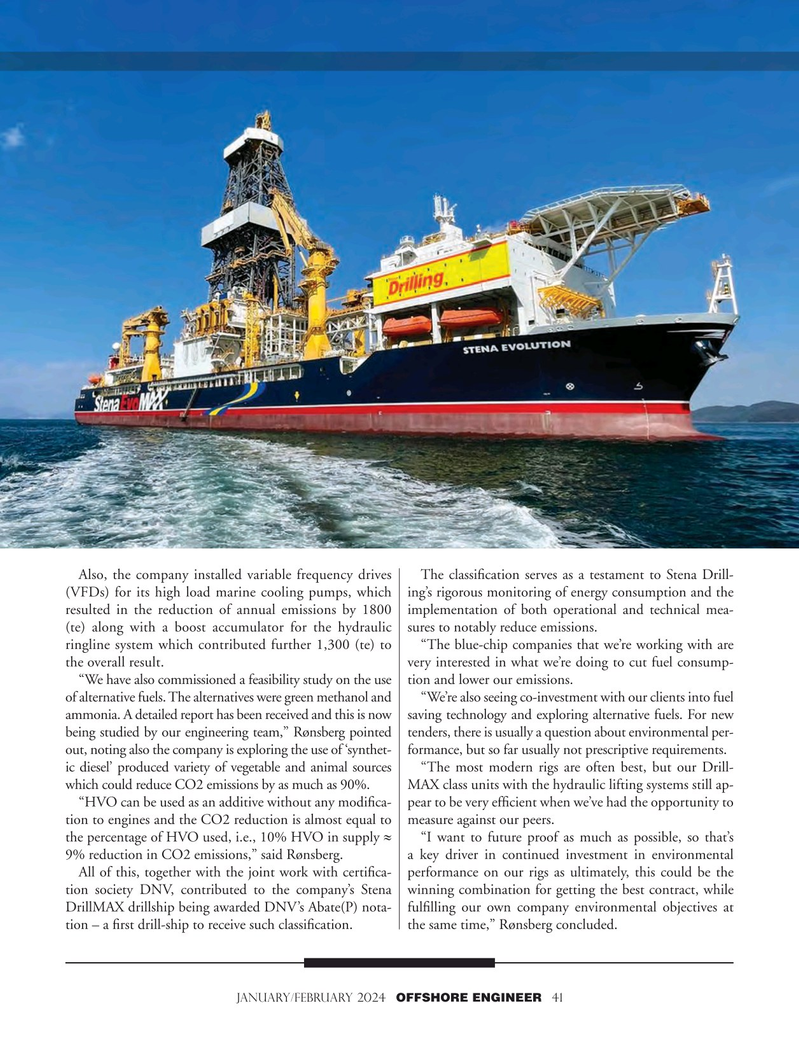

All of this, together with the joint work with certifca- performance on our rigs as ultimately, this could be the tion society DNV, contributed to the company’s Stena winning combination for getting the best contract, while

DrillMAX drillship being awarded DNV’s Abate(P) nota- fulflling our own company environmental objectives at tion – a frst drill-ship to receive such classifcation. the same time,” Rønsberg concluded.

january/february 2024 OFFSHORE ENGINEER 41

40

40

42

42