Red and White and Green All Over

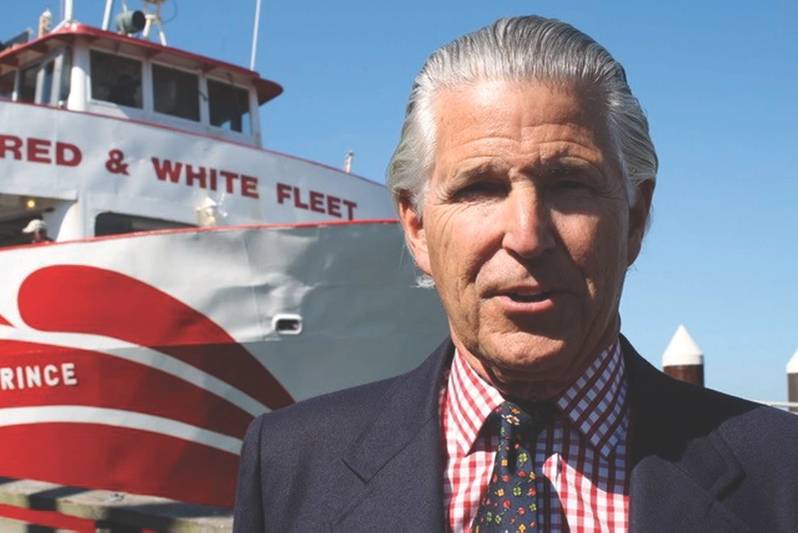

INSIGHTS: Thomas C. Escher, Chairman, Red and White Fleet

In 1960, Tom Escher, the grandson of the founder and now the current owner, started working as a sweeper and a mechanics helper on the Red and White vessels. In 1997, Escher purchased the Red and White Fleet, becoming the third generation of the family to own and operate the business. In September 2018, Red and White Fleet welcomed Enhydra, the newest and largest addition to the fleet. Enhydra is the first 600-passenger hybrid-drive vessel operating in the United States. Escher will be building more zero pollution passenger vessels.

Red and White is a family-owned company, with roots stretching back to the original Crowley Bay area businesses. Give us a quick description of your firm’s history – from inception to present day.

The firm was founded by my grandfather, Tom Crowley, in 1892. In time, it grew to become an international transport company with the name of Crowley Maritime Corporation. In 1997, I purchased the Red and White Fleet (RWF). Hence, my first cousin, Tom Crowley, Jr, is running Crowley and I am running Red and White Fleet. Today, the only financial differences between the two companies are the zeros.

Give us a ‘by the numbers’ insight on Red and White.

We have a total of four vessels in our fleet. Less than 1 million passengers embark on our cruises annually.

You are known for being passionate about the environment. And, you have made no secret of the fact that you want to build new vessels with zero environmental signatures. Where are you on that journey?

Our goal – which we will achieve – is to be operating zero pollution vessels. As of today, we are failing in our environmental goals because our entire fleet is not yet zero pollution. It is difficult and/or impossible for me to say ‘The Red and White Fleet is an environmentally sensitive and we operate cleaner vessels.’ Many stakeholders use the environmental discussion as a marketing ploy to show that they are cleaner or an environmentally sensitive business. In truth, a business is either ‘zero pollution’ or is not ‘zero pollution.’

You are a member of the PVA’s GreenWaters Program. Your firm boasts a long history of environmental commitment – beyond simple propulsion itself – in your daily operations. It sounds good, but what does that really entail?

We support the PVA’s GreenWater Program as it is a very good industry program. It is relatively easy to achieve many of these goals but RWF is still not zero pollution, so the Red and White Fleet still has a long way to go on its journey to become zero pollution.

Tom Escher (Photo: Red and White Fleet)

Tom Escher (Photo: Red and White Fleet)

Do you employ a so-called ‘safety management system?’

Yes. We have an in-house safety management system (SMS) that has taken its roots and structure from many other SMS programs.

Red and White is an early adopter of alternative fuels, among other things. Which alternative fuels do you now employ and which ones are being investigated?

Since we are a small company, it is difficult for us to spend big dollars on exploring the many potential fuels in the world. We are looking are looking at electric, hydrogen, etc. However, I am hopeful that in the near future, there will be a significant discovery for a new, different zero pollution power system for ships.

The Golden State wants all ports to be ‘carbon neutral’ by 2030. Red and White is on its way to doing just that, but of course it comes at a cost. How do you manage to stay competitive?

It is very difficult. Yes, there is a dollar cost, but let’s not forget the human health cost. We believe that RWF offers the best sightseeing and vessel operation on San Francisco Bay. At the same time, if the consumer wants another type of service; then that is their choice.

Can a firm go green for the right reasons and fatten the bottom line at the same time?

Bottom line is important. Humans are important. Business continuity is important. These differences must work together or there will be larger global problems.

What do your vessels run on now?

We have been operating on 100% renewable diesel produced by Neste MY, and we are getting good results.

Your Enhydra is certainly not an average tour vessel. Can you share the main challenges in its construction, how has the vessel performed post-delivery and ‘lessons-learned’ to date?

First, we had simply great vessel performance, great support from All American Marine and great support from BAE. This vessel involves very different operations for the captains, and additional training was necessary as we rolled out this new technology. For example, silent operations involve the master to look at the monitors and not listen to the diesel engines. Almost instant throttle response times, require a gentle touch with controls. Additional training was also required for our maintenance teams, who, to their ultimate credit, were very quick to catch on. Today, everyone notices and comments on the cleanliness of the engine spaces, which still shine like the day we took delivery of the vessel. In terms of service, passengers now recognize no diesel odors, no exhaust, a quiet operational ride, no soot on the vessel, and many other related improvements.

Red and White Fleet’s lithium ion battery hybrid vessel brought 20% fuel efficiencies over conventional diesel engine propulsion systems. You’ve said you can and intend to do better. Are we there yet?

We are performing with 35% efficiencies over conventional diesel – the 20% was the original goal; 35% is our actual results.

Red and White intends to eventually bring the first hydrogen fuel cell powered vessel into service in the San Francisco Bay Area. When will that happen and how will you pay for it?

We are presently working with another company and the California Air Resources Board (CARB) to build a high-speed hydrogen fuel cell ferry to operate on San Francisco Bay. This vessel, named the Water Go Round, will show the maritime industry that hydrogen fuel cell vessels are a reality and zero pollutes here today. I suggest you go to Sandia National Lab’s website as they have completed a feasibility study on both electric and hydrogen fuel cell vessels, including large containerships. There is very good information in that Sandia study.

The U.S. Department of Transportation insists that it focuses on rebuilding, repairing and revitalizing our transportation infrastructure. Yet, there are many U.S. flag operators – specifically those in the passenger vessel game – at an enormous disadvantage because today’s interpretation of the MARAD Capital Construction Program (CCF) excludes these operators from all the benefits of this well-intentioned program. Why is this happening?

Let’s be truthful: the CCF is an exclusive club mainly intended for large deep-sea vessel operators and, of course, others who have the lobbying dollars to control the decision makers. MARAD’s website insists, “… we work hard to maintain the overall health of the U.S. Merchant Marine.” If that is true, then why does MARAD not support all U.S. flag vessels in utilizing the CCF? H. Clayton Cook (a recognized and well known CCF expert) and I are willing to meet with MARAD (again) at any time to shift the CCF from an ‘exclusive club’ to a CCF open to all U.S. flag operators. Industry knows that this will create new shipyard jobs, add more U.S. flag vessels and build a stronger merchant marine. Sadly, RWF does not have any lobbying dollars to pressure MARAD, so the CCF remains and exclusive club mainly for large deep-sea vessel operators. If any of your readers interested in a more inclusive CCF and building a stronger U.S. Merchant Marine, please have them contact me.

The 128-foot, 600-passenger Enhydra is the first aluminum hulled, lithium-Ion battery plug-in hybrid vessel built in the U.S. (Photo: All American Marine)

The 128-foot, 600-passenger Enhydra is the first aluminum hulled, lithium-Ion battery plug-in hybrid vessel built in the U.S. (Photo: All American Marine)

This year, the U.S. EPA proposed to delay implementation of Tier 4 marine diesel engines “in certain high-speed commercial vessels.” What are your immediate thoughts on this proposal?

If you are a global engine manufacturer, why would your company decide to make/modify engines to meet tier 4 engine requirements as needed by CARB? Actually, it is probably less expensive for engine manufacturers to drag their feet and spend lobbying dollars for one state and delay the implementation of the rules. Again, are we back to touting simply ‘cleaner solutions’ to keep the public happy, or should we proceed with a zero pollution goal? EPA’s latest proposal therefore casts doubt whether federal decision makers honestly care about pollution or are merely providing lip service.

Supposedly, and for boat-builders, Tier 4 engine size and weight present challenges. Do these challenges warrant further delay? Do these challenges impact your firm’s operations?

It is the job of boat-builders and naval architects to “figure it out.” Alternatively, they can go out of business while someone else will.

The Maine Lobstermen’s Association supports EPA’s proposed delay, saying “the current Tier 4 marine diesel engine emission standard is a mismatch for the Maine lobster fleet.” But, what about ferries and passenger vessels; does the same hold true?

The mission of EPA is to protect human health and the environment. Many businesses and citizens respect and admire the EPA. However, in many cases, as soon as the implementation of proposed standards has an effect on a business or individual, then there is a need to ‘kick the can down the road.’ In this specific case, some of the reasoning presented to the EPA seems to be that the technology is ‘simply not available or feasible,’ or perhaps the time-tested excuse of ‘the decade-old assumption of how the market would respond has proven to be incorrect.’ And, of course, who could forget, ‘it is a question of whether there are likely to be enough sales to justify the manufacture’s investment, etc.’ As a vessel owner and operator, many of the EPA actions have a financial impact on businesses and I accept this additional cost because I am extremely concerned about human health and the environment. As I understand it, the EPA is responsible to lead the way and the public is relying on the EPA to do their job. We therefore urge the EPA not to amend the proposed standards as there is no more room to ‘kick the can down the road.’

For operators in small bays and fixed routes, DEF for SCR Tier 4 implementation is not a problem. The supply chain can be set in quite easily. Towboat operators on the rivers say that’s not the case. In these remote areas, sometimes there is no (DEF) distribution network. Can this problem be overcome in the short term to avoid pushing the environmental concerns ‘can’ down the road?

Stop. Please stop: companies must stop providing lip service for ‘cleaner’ operations and then be bold enough to make changes to zero pollution operations. In other words, spend your lobbying dollars on zero pollution engines.

Read Red and White and Green All Over in Pdf, Flash or Html5 edition of January 2020 Marine News

Other stories from January 2020 issue

Content

- Red and White and Green All Over page: 12

- Fishing for Trouble page: 16

- An Ever-vigilant Focus on Passenger Vessel Safety page: 18

- Ferry Industry Sets Pace on Critical Solutions page: 20

- Vessel Safety: US House Subcommittee Seeks Faster Implementation page: 24

- Vessel Inspections: It's All About Safety page: 28

- Safely Navigating the Winds of Change page: 34

- Water Audits at Sea page: 39

- Tech File: Grain Monitoring System for Loaded Barges page: 42