Page 39: of Maritime Logistics Professional Magazine (Q4 2013)

Shipbuilding, Repair

Read this page in Pdf, Flash or Html5 edition of Q4 2013 Maritime Logistics Professional Magazine

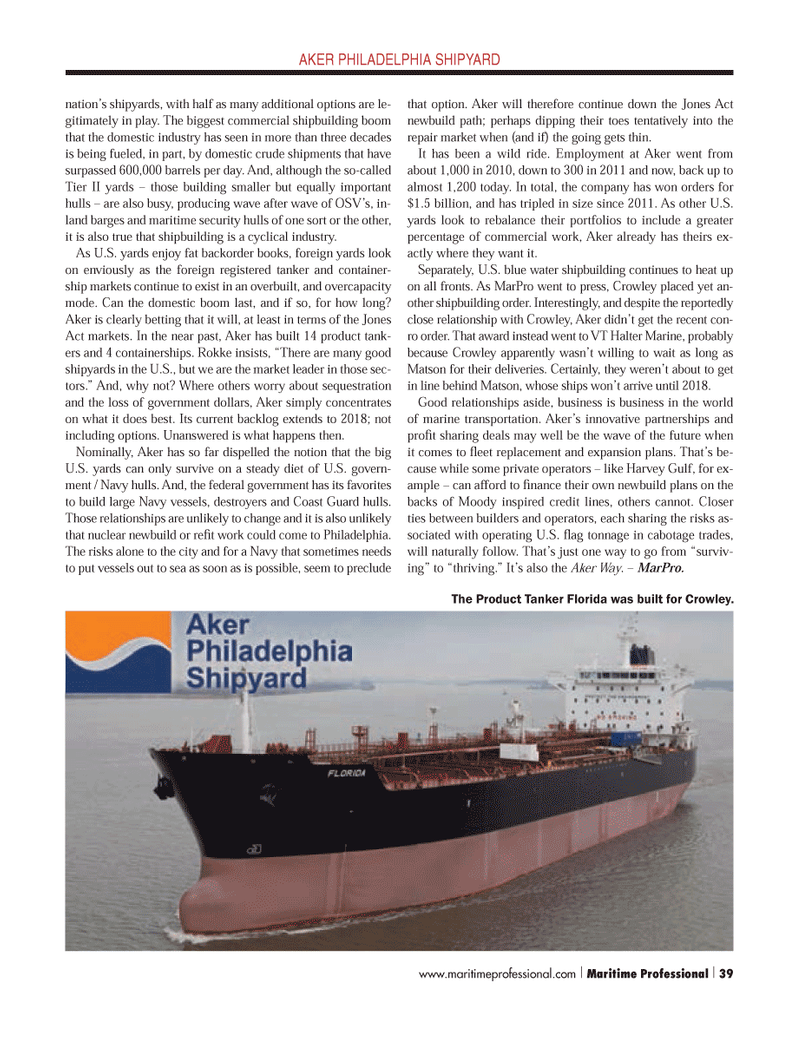

AKER PHILADELPHIA SHIPYARD nation?s shipyards, with half as many additional options are le- gitimately in play. The biggest commercial shipbuilding boom that the domestic industry has seen in more than three decades is being fueled, in part, by domestic crude shipments that have surpassed 600,000 barrels per day. And, although the so-called Tier II yards ? those building smaller but equally important hulls ? are also busy, producing wave after wave of OSV?s, in- land barges and maritime security hulls of one sort or the other, it is also true that shipbuilding is a cyclical industry. As U.S. yards enjoy fat backorder books, foreign yards look on enviously as the foreign registered tanker and container- ship markets continue to exist in an overbuilt, and overcapacity mode. Can the domestic boom last, and if so, for how long? Aker is clearly betting that it will, at least in terms of the Jones Act markets. In the near past, Aker has built 14 product tank- ers and 4 containerships. Rokke insists, ?There are many good shipyards in the U.S., but we are the market leader in those sec- tors.? And, why not? Where others worry about sequestration and the loss of government dollars, Aker simply concentrates on what it does best. Its current backlog extends to 2018; not including options. Unanswered is what happens then.Nominally, Aker has so far dispelled the notion that the big U.S. yards can only survive on a steady diet of U.S. govern- ment / Navy hulls. And, the federal government has its favorites to build large Navy vessels, destroyers and Coast Guard hulls. Those relationships are unlikely to change and it is also unlikely that nuclear newbuild or re t work could come to Philadelphia. The risks alone to the city and for a Navy that sometimes needs to put vessels out to sea as soon as is possible, seem to preclude that option. Aker will therefore continue down the Jones Act newbuild path; perhaps dipping their toes tentatively into the repair market when (and if) the going gets thin. It has been a wild ride. Employment at Aker went from about 1,000 in 2010, down to 300 in 2011 and now, back up to almost 1,200 today. In total, the company has won orders for $1.5 billion, and has tripled in size since 2011. As other U.S. yards look to rebalance their portfolios to include a greater percentage of commercial work, Aker already has theirs ex- actly where they want it. Separately, U.S. blue water shipbuilding continues to heat up on all fronts. As MarPro went to press, Crowley placed yet an- other shipbuilding order. Interestingly, and despite the reportedly close relationship with Crowley, Aker didn?t get the recent con- ro order. That award instead went to VT Halter Marine, probably because Crowley apparently wasn?t willing to wait as long as Matson for their deliveries. Certainly, they weren?t about to get in line behind Matson, whose ships won?t arrive until 2018. Good relationships aside, business is business in the world of marine transportation. Aker?s innovative partnerships and pro t sharing deals may well be the wave of the future when it comes to eet replacement and expansion plans. That?s be- cause while some private operators ? like Harvey Gulf, for ex- ample ? can afford to nance their own newbuild plans on the backs of Moody inspired credit lines, others cannot. Closer ties between builders and operators, each sharing the risks as- sociated with operating U.S. ag tonnage in cabotage trades, will naturally follow. That?s just one way to go from ?surviv- ing? to ?thriving.? It?s also the Aker Way . ? MarPro.The Product Tanker Florida was built for Crowley. www.maritimeprofessional.com | Maritime Professional | 39MP #4 34-49.indd 39MP #4 34-49.indd 3912/11/2013 1:25:15 PM12/11/2013 1:25:15 PM

38

38

40

40