Page 39: of Maritime Logistics Professional Magazine (Mar/Apr 2019)

Container Ports

Read this page in Pdf, Flash or Html5 edition of Mar/Apr 2019 Maritime Logistics Professional Magazine

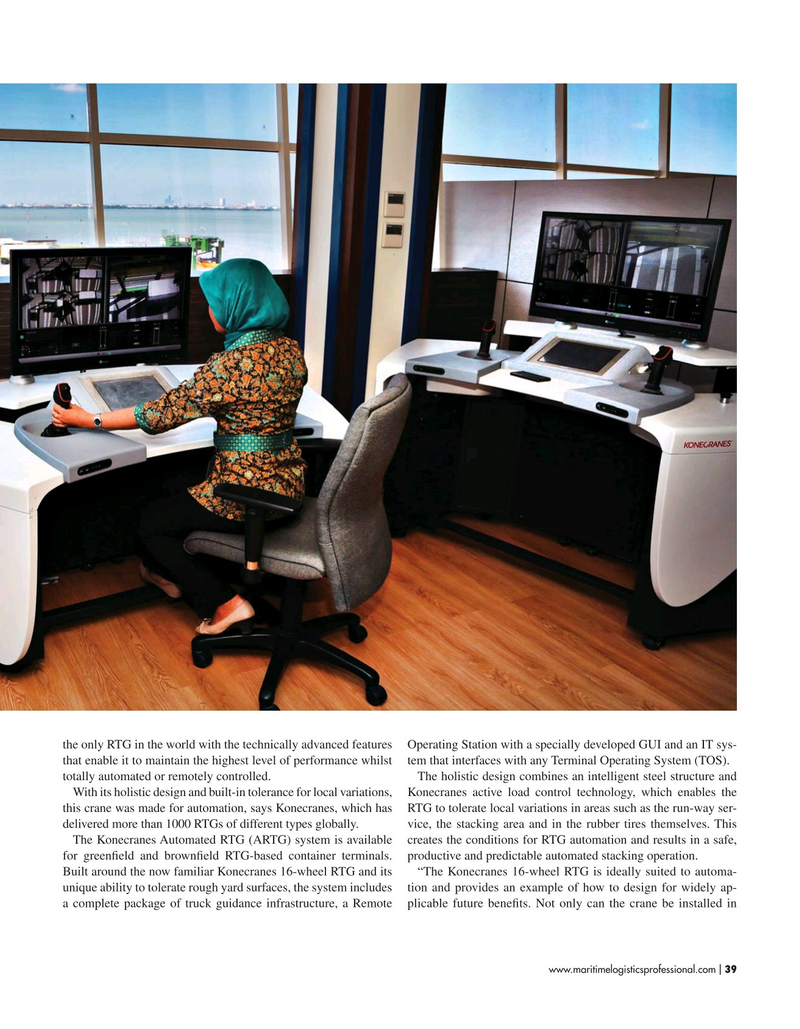

the only RTG in the world with the technically advanced features Operating Station with a specially developed GUI and an IT sys- that enable it to maintain the highest level of performance whilst tem that interfaces with any Terminal Operating System (TOS).

totally automated or remotely controlled. The holistic design combines an intelligent steel structure and

With its holistic design and built-in tolerance for local variations, Konecranes active load control technology, which enables the this crane was made for automation, says Konecranes, which has RTG to tolerate local variations in areas such as the run-way ser- delivered more than 1000 RTGs of different types globally. vice, the stacking area and in the rubber tires themselves. This

The Konecranes Automated RTG (ARTG) system is available creates the conditions for RTG automation and results in a safe, for green?eld and brown?eld RTG-based container terminals. productive and predictable automated stacking operation.

Built around the now familiar Konecranes 16-wheel RTG and its “The Konecranes 16-wheel RTG is ideally suited to automa- unique ability to tolerate rough yard surfaces, the system includes tion and provides an example of how to design for widely ap- a complete package of truck guidance infrastructure, a Remote plicable future bene?ts. Not only can the crane be installed in www.maritimelogisticsprofessional.com 39

I

38

38

40

40