Page 40: of Maritime Logistics Professional Magazine (Mar/Apr 2019)

Container Ports

Read this page in Pdf, Flash or Html5 edition of Mar/Apr 2019 Maritime Logistics Professional Magazine

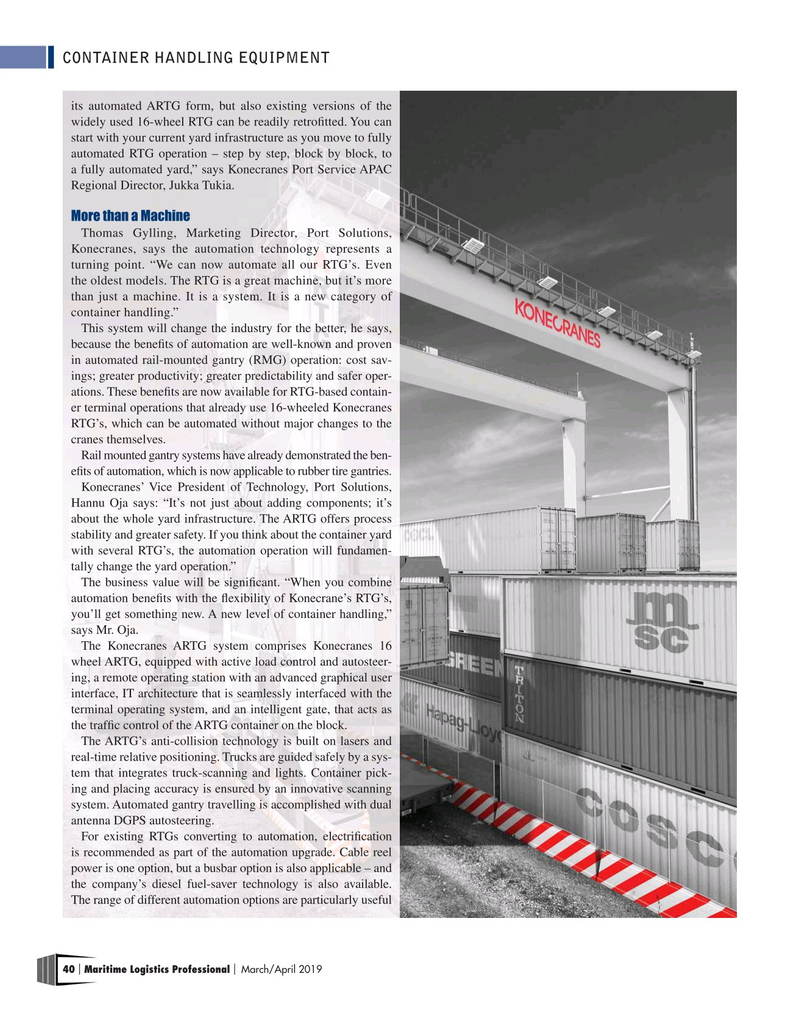

CONTAINER HANDLING EQUIPMENT its automated ARTG form, but also existing versions of the widely used 16-wheel RTG can be readily retro?tted. You can start with your current yard infrastructure as you move to fully automated RTG operation – step by step, block by block, to a fully automated yard,” says Konecranes Port Service APAC

Regional Director, Jukka Tukia.

More than a Machine

Thomas Gylling, Marketing Director, Port Solutions,

Konecranes, says the automation technology represents a turning point. “We can now automate all our RTG’s. Even the oldest models. The RTG is a great machine, but it’s more than just a machine. It is a system. It is a new category of container handling.”

This system will change the industry for the better, he says, because the bene?ts of automation are well-known and proven in automated rail-mounted gantry (RMG) operation: cost sav- ings; greater productivity; greater predictability and safer oper- ations. These bene?ts are now available for RTG-based contain- er terminal operations that already use 16-wheeled Konecranes

RTG’s, which can be automated without major changes to the cranes themselves.

Rail mounted gantry systems have already demonstrated the ben- e?ts of automation, which is now applicable to rubber tire gantries.

Konecranes’ Vice President of Technology, Port Solutions,

Hannu Oja says: “It’s not just about adding components; it’s about the whole yard infrastructure. The ARTG offers process stability and greater safety. If you think about the container yard with several RTG’s, the automation operation will fundamen- tally change the yard operation.”

The business value will be signi?cant. “When you combine automation bene?ts with the ?exibility of Konecrane’s RTG’s, you’ll get something new. A new level of container handling,” says Mr. Oja.

The Konecranes ARTG system comprises Konecranes 16 wheel ARTG, equipped with active load control and autosteer- ing, a remote operating station with an advanced graphical user interface, IT architecture that is seamlessly interfaced with the terminal operating system, and an intelligent gate, that acts as the traf?c control of the ARTG container on the block.

The ARTG’s anti-collision technology is built on lasers and real-time relative positioning. Trucks are guided safely by a sys- tem that integrates truck-scanning and lights. Container pick- ing and placing accuracy is ensured by an innovative scanning system. Automated gantry travelling is accomplished with dual antenna DGPS autosteering.

For existing RTGs converting to automation, electri?cation is recommended as part of the automation upgrade. Cable reel power is one option, but a busbar option is also applicable – and the company’s diesel fuel-saver technology is also available.

The range of different automation options are particularly useful 40 Maritime Logistics Professional March/April 2019 | |

39

39

41

41