Page 48: of Maritime Reporter Magazine (August 15, 1969)

Read this page in Pdf, Flash or Html5 edition of August 15, 1969 Maritime Reporter Magazine

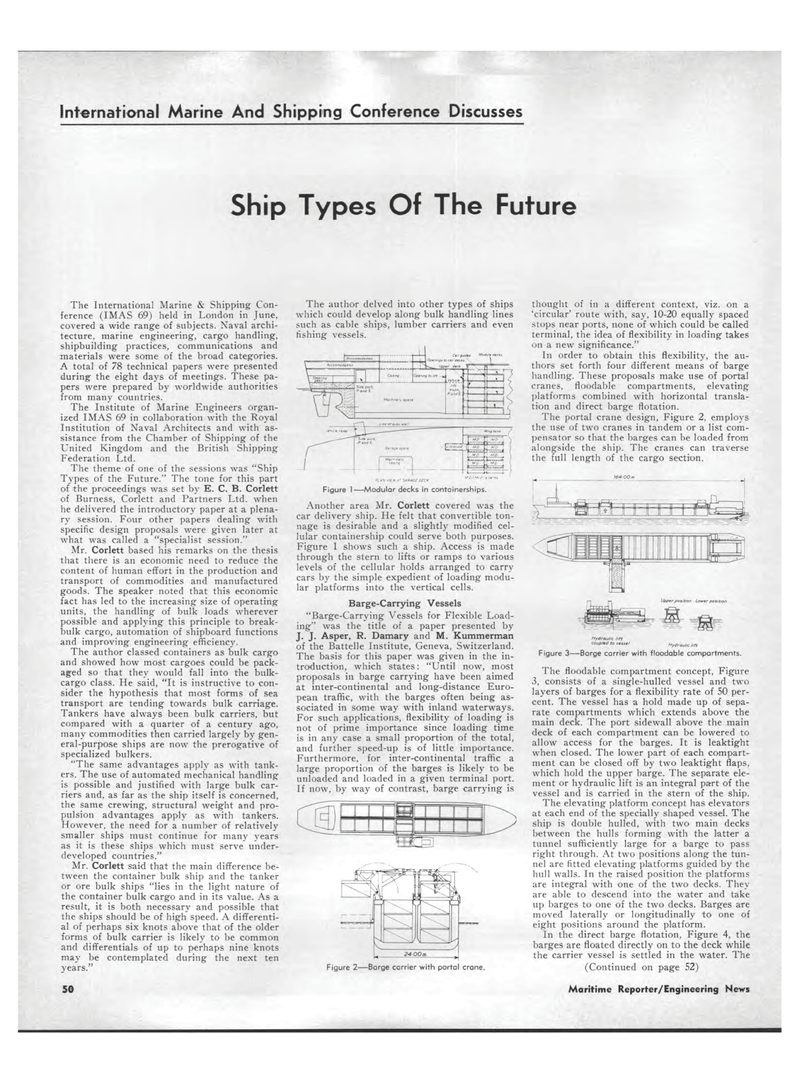

International Marine And Shipping Conference Discusses Ship The International Marine & Shipping Con-ference (IMAS 69) held in London in June, covered a wide range of subjects. Naval archi-tecture, marine engineering, cargo handling, shipbuilding practices, communications and materials were some of the broad categories. A total of 78 technical papers were presented during the eight days of meetings. These pa-pers were prepared by worldwide authorities from many countries. The Institute of Marine Engineers organ-ized IMAS 69 in collaboration with the Royal Institution of Naval Architects and with as-sistance from the Chamber of Shipping of the United Kingdom and the British Shipping Federation Ltd. The theme of one of the sessions was "Ship Types of the Future." The tone for this part of the proceedings was set by E. C. B. Corlett of Burness, Corlett and Partners Ltd. when he delivered the introductory paper at a plena-ry session. Four other papers dealing with specific design proposals were given later at what was called a "specialist session." Mr. Corlett based his remarks on the thesis that there is an economic need to reduce the content of human effort in the production and transport of commodities and manufactured goods. The speaker noted that this economic fact has led to the increasing size of operating units, the handling of bulk loads wherever possible and applying this principle to break-bulk cargo, automation of shipboard functions and improving engineering efficiency. The author classed containers as bulk cargo and showed how most cargoes could be pack-aged so that they would fall into the bulk-cargo class. He said, "It is instructive to con-sider the hypothesis that most forms of sea transport are tending towards bulk carriage. Tankers have always been bulk carriers, but compared with a quarter of a century ago, many commodities then carried largely by gen-eral-purpose ships are now the prerogative of specialized bulkers. "The same advantages apply as with tank-ers. The use of automated mechanical handling is possible and justified with large bulk car-riers and, as far as the ship itself is concerned, the same crewing, structural weight and pro-pulsion advantages apply as with tankers. However, the need for a number of relatively smaller ships must continue for many years as it is these ships which must serve under-developed countries." Mr. Corlett said that the main difference be-tween the container bulk ship and the tanker or ore bulk ships "lies in the light nature of the container bulk cargo and in its value. As a result, it is both necessary and possible that the ships should be of high speed. A differenti-al of perhaps six knots above that of the older forms of bulk carrier is likely to be common and differentials of up to perhaps nine knots may be contemplated during the next ten years." Types Of The Future The author delved into other types of ships which could develop along bulk handling lines such as cable ships, lumber carriers and even fishing vessels. . /'/*-* ~,ABAGE DECK Figure 1?Modular decks in containerships. Another area Mr. Corlett covered was the car delivery ship. He felt that convertible ton-nage is desirable and a slightly modified cel-lular containership could serve both purposes. Figure 1 shows such a ship. Access is made through the stern to lifts or ramps to various levels of the cellular holds arranged to carry cars by the simple expedient of loading modu-lar platforms into the vertical cells. Barge-Carrying Vessels "Barge-Carrying Vessels for Flexible Load-ing" was the title of a paper presented by J. J. Asper, R. Damary and M. Kummerman of the Battelle Institute, Geneva, Switzerland. The basis for this paper was given in the in-troduction, which states: "Until now, most proposals in barge carrying have been aimed at inter-continental and long-distance Euro-pean traffic, with the barges often being as-sociated in some way with inland waterways. For such applications, flexibility of loading is not of prime importance since loading time is in any case a small proportion of the total, and further speed-up is of little importance. Furthermore, for inter-continental traffic a large proportion of the barges is likely to be unloaded and loaded in a given terminal port. If now, by way of contrast, barge carrying is thought of in a different context, viz. on a 'circular' route with, say, 10-20 equally spaced stops near ports, none of which could be called terminal, the idea of flexibility in loading takes on a new significance." In order to obtain this flexibility, the au-thors set forth four different means of barge handling. These proposals make use of portal cranes, floodable compartments, elevating platforms combined with horizontal transla-tion and direct barge flotation. The portal crane design, Figure 2, employs the use of two cranes in tandem or a list com-pensator so that the barges can be loaded from alongside the ship. The cranes can traverse the full length of the cargo section. Figure 2?Barge carrier with portal crane. Hydraulic lift coupled to vessel Hydraulic IIIt Figure 3?Barge carrier with floodable compartments. The floodable compartment concept, Figure 3, consists of a single-hulled vessel and two layers of barges for a flexibility rate of 50 per-cent. The vessel has a hold made up of sepa-rate compartments which extends above the main deck. The port sidewall above the main deck of each compartment can be lowered to allow access for the barges. It is leaktight when closed. The lower part of each compart-ment can be closed off by two leaktight flaps, which hold the upper barge. The separate ele-ment or hydraulic lift is an integral part of the vessel and is carried in the stern of the ship. The elevating platform concept has elevators at each end of the specially shaped vessel. The ship is double hulled, with two main decks between the hulls forming with the latter a tunnel sufficiently large for a barge to pass right through. At two positions along the tun-nel are fitted elevating platforms guided by the hull walls. In the raised position the platforms are integral with one of the two decks. They are able to descend into the water and take up barges to one of the two decks. Barges are moved laterally or longitudinally to one of eight positions around the platform. In the direct barge flotation, Figure 4, the barges are floated directly on to the deck while the carrier vessel is settled in the water. The (Continued on page 52) 50 Maritime Reporter/Engineering News

47

47

49

49