Page 26: of Maritime Reporter Magazine (December 15, 1983)

Read this page in Pdf, Flash or Html5 edition of December 15, 1983 Maritime Reporter Magazine

91st SNAME

Annual Meeting

Special Report (continued from page 25) • Frank S.F. Chou, Susobhan

Ghosh, and Edward W.

Haung, "Conceptual Design

Process of a Tension Leg

Platform;" • Joseph D. Porricelli, J.

Huntly Boyd, and Keith E.

Schleiffer, "Modern Analyti- cal Techniques for Salvage

Engineering Using Portable

Computers;" • Thomas V. Kotras, Andrew

V. Baird, and John N. Nae- gle, "Predicting Ship Per- formance in Level Ice;" and • Alexander C. Landsburg,

James C. Card, C. Lincoln

Crane, Jr., Philip R. Al- man, William R. Bertsche,

John W. Boylston, Haruzo

Eda, Virgil F. Keith, Ian R.

McCallum, Eugene R. Miller

Jr., and Abraham Taplin, "Design and Verification for

Adequate Ship Maneuver- ability

Second International

Maritime Exposition

As mentioned briefly at the be-

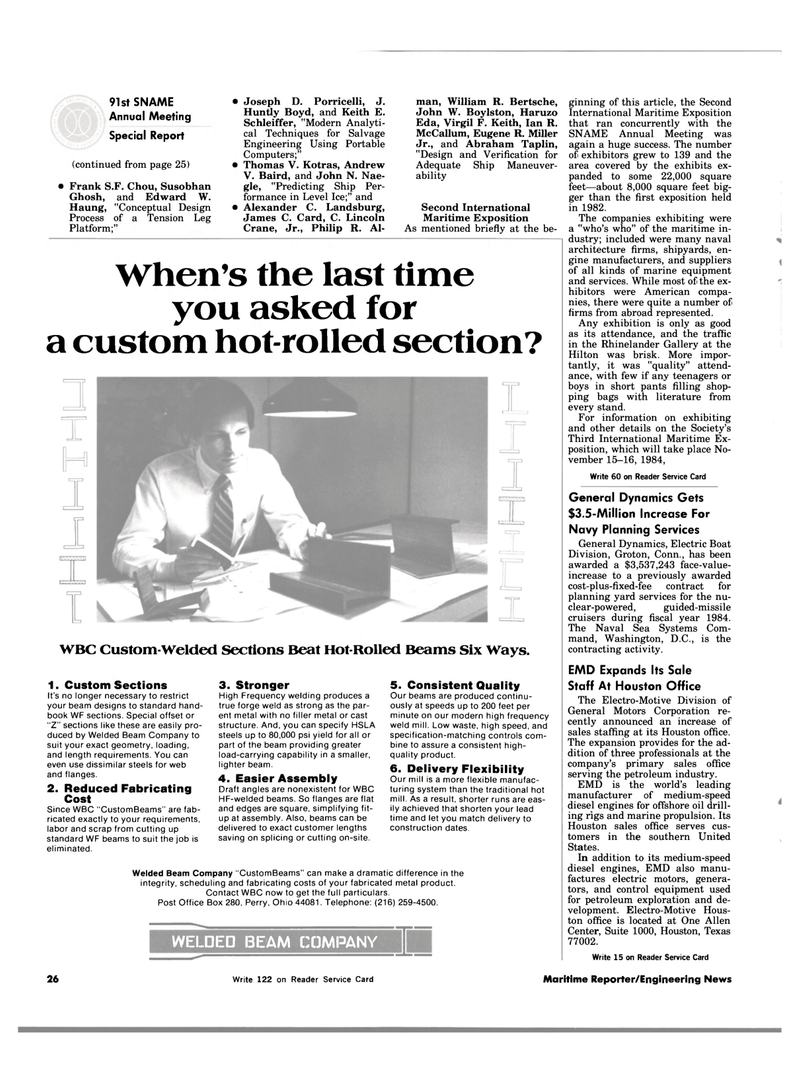

When's the last time you asked for a custom hot-rolled section?

WBC Custom-Welded Sections Beat Hot-Rolled Beams Six Ways. 1. Custom Sections

It's no longer necessary to restrict your beam designs to standard hand- book WF sections. Special offset or "Z" sections like these are easily pro- duced by Welded Beam Company to suit your exact geometry, loading, and length requirements. You can even use dissimilar steels for web and flanges. 2. Reduced Fabricating

Cost

Since WBC "CustomBeams" are fab- ricated exactly to your requirements, labor and scrap from cutting up standard WF beams to suit the job is eliminated. 3. Stronger

High Frequency welding produces a true forge weld as strong as the par- ent metal with no filler metal or cast structure. And, you can specify HSLA steels up to 80,000 psi yield for all or part of the beam providing greater load-carrying capability in a smaller, lighter beam. 4. Easier Assembly

Draft angles are nonexistent for WBC

HF-welded beams. So flanges are flat and edges are square, simplifying fit- up at assembly. Also, beams can be delivered to exact customer lengths saving on splicing or cutting on-site. 5. Consistent Quality

Our beams are produced continu- ously at speeds up to 200 feet per minute on our modern high frequency weld mill. Low waste, high speed, and specification-matching controls com- bine to assure a consistent high- quality product. 6. Delivery Flexibility

Our mill is a more flexible manufac- turing system than the traditional hot mill. As a result, shorter runs are eas- ily achieved that shorten your lead time and let you match delivery to construction dates.

Welded Beam Company "CustomBeams" can make a dramatic difference in the integrity, scheduling and fabricating costs of your fabricated metal product.

Contact WBC now to get the full particulars.

Post Office Box 280, Perry, Ohio 44081. Telephone: (216) 259-4500. ginning of this article, the Second

International Maritime Exposition that ran concurrently with the

SNAME Annual Meeting was again a huge success. The number of exhibitors grew to 139 and the area covered by the exhibits ex- panded to some 22,000 square feet—about 8,000 square feet big- ger than the first exposition held in 1982.

The companies exhibiting were a "who's who" of the maritime in- dustry; included were many naval architecture firms, shipyards, en- gine manufacturers, and suppliers of all kinds of marine equipment and services. While most of the ex- hibitors were American compa- nies, there were quite a number of firms from abroad represented.

Any exhibition is only as good as its attendance, and the traffic in the Rhinelander Gallery at the

Hilton was brisk. More impor- tantly, it was "quality" attend- ance, with few if any teenagers or boys in short pants filling shop- ping bags with literature from every stand.

For information on exhibiting and other details on the Society's

Third International Maritime Ex- position, which will take place No- vember 15-16, 1984,

Write 60 on Reader Service Card

General Dynamics Gets $3.5-Million Increase For

Navy Planning Services

General Dynamics, Electric Boat

Division, Groton, Conn., has been awarded a $3,537,243 face-value- increase to a previously awarded cost-plus-fixed-fee contract for planning yard services for the nu- clear-powered, guided-missile cruisers during fiscal year 1984.

The Naval Sea Systems Com- mand, Washington, D.C., is the contracting activity.

EMD Expands Its Sale

Staff At Houston Office

The Electro-Motive Division of

General Motors Corporation re- cently announced an increase of sales staffing at its Houston office.

The expansion provides for the ad- dition of three professionals at the company's primary sales office serving the petroleum industry.

EMD is the world's leading manufacturer of medium-speed diesel engines for offshore oil drill- ing rigs and marine propulsion. Its

Houston sales office serves cus- tomers in the southern United

States.

In addition to its medium-speed diesel engines, EMD also manu- factures electric motors, genera- tors, and control equipment used for petroleum exploration and de- velopment. Electro-Motive Hous- ton office is located at One Allen

Center, Suite 1000, Houston, Texas 77002.

Write 15 on Reader Service Card

WELDED BEAM COMPANY 26 Write 122 on Reader Service Card Maritime Reporter/Engineering News

25

25

27

27