Page 57: of Maritime Reporter Magazine (April 1995)

Read this page in Pdf, Flash or Html5 edition of April 1995 Maritime Reporter Magazine

Safety Study Focuses On Machinery I n 1994 some prominent mem- bers of the shipping commu- nity formed the Redundant

Ship Machinery Consortium, with the overall goal of increasing the machinery-related safety of mer- chant ships.

Findings of the consortium were divulged recently via a paper at a tanker industry convention.

Focus On Safety

While the project focused mainly on propulsion machinery, it also explored steering machinery. A cornerstone of the project was that ships — such as tankers and pas- senger vessels — should not be built with machinery concepts, con- taining many components in the engine room, the single failure of any of which is critical for the pro- pulsion or for the maneuvering of the vessel.

Fully redundant machinery so- lutions generally have inherent advantages, the consortium found, such as good availability and ma- neuverability. Other forces push- ing the drive for redundancy in- clude growing interest among ship- owners and pending legislation.

Setting The Standards

The implementation of redun- dancy requires clear criteria, and such criteria will be available this

July in the form of voluntary class notations issued by Det Norske

Veritas, developed as part of the project.

Technical solutions which comply with these rules to come were pre- sented in the context of the project as well. The solutions are based on a twin-screw/twin-rudder configu- ration including system redundancy, with the higher degree of redun- dancy featuring a fire-insulated wa- tertight separation bulkhead.

One conclusion of the project was that, for a comparatively small extra cost, ships can be built to comply with the most stringent of the new class notations, with the following criteria:

At least 50 percent of the propul- sion power and adequate steering capability of the ship will be main- tained in the following situations: • A single failure of any component in the propulsion or steering ma- chinery or related auxiliary piping, ducting, electrical or other systems supplying it • A fire of whatever size in any (but only one) machinery space or control room • Flooding of any (but only one) watertight compartment.

The Redundant Ship Machinery

Project brought together several prestigious organizations in an ef- fort to successfully blend the techni- cal, financial and rules-related is- sues into a cohesive conclusion.

Here's a rundown of the participants and their roles.

For more information on any of the companies listed, circle the cor- responding number on the Reader

Service Card in this issue.

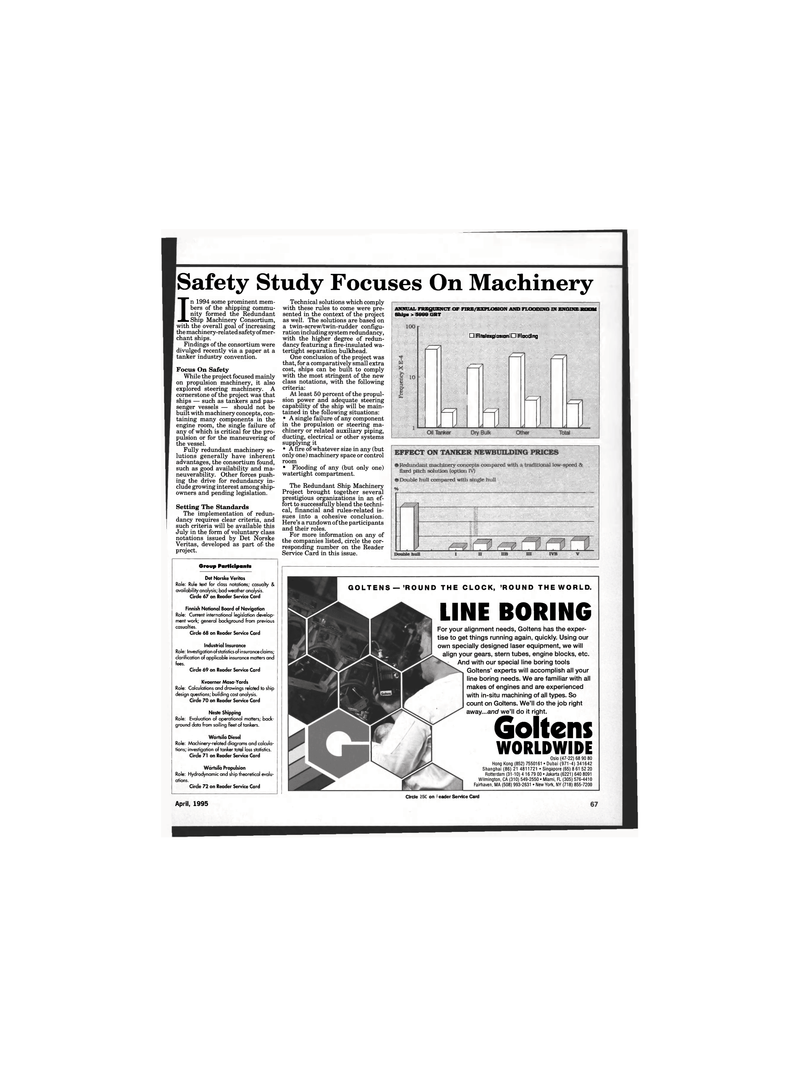

ANNUAL FREQUENCY OF FIRE/EXPLOSION AND FLOODING IN ENGINE ROOM

Ships > 5999 GRT • Fife/explosion • Flooding

Finnish National Board of Navigation

Role: Current international legislation develop- ment work; general background from previous casualties.

Circle 68 on Reader Service Card

Industrial Insurance

Role: Investigation of statistics of insuranceclaims; clarification of applicable insurance matters and fees.

Circle 69 on Reader Service Card

Kvaerner Masa-Yards

Role: Calculations and drawings related to ship design questions; building cost analysis.

Circle 70 on Reader Service Card

Group Participants

Det Norske Veritas

Role: Rule text for class notations; casualty & availability analysis; bad weather analysis.

Circle 67 on Reader Service Card

GOLTENS — 'ROUND THE CLOCK, 'ROUND THEWORLD.

LINE BORING

Neste Shipping

Role: Evaluation of operational matters; back- ground data from sailing fleet of tankers.

Wartsila Diesel

Role: Machinery-related diagrams and calcula- tions; investigation of tanker total loss statistics.

Circle 71 on Reader Service Card

Wartsila Propulsion

Role: Hydrodynamic and ship theoretical evalu- ations.

Circle 72 on Reader Service Card

April, 1995 39

For your alignment needs, Goltens has the exper- tise to get things running again, quickly. Using our own specially designed laser equipment, we will align your gears, stern tubes, engine blocks, etc.

And with our special line boring tools

Goltens' experts will accomplish all your line boring needs. We are familiar with all makes of engines and are experienced with in-situ machining of all types. So count on Goltens. We'll do the job right away...and we'll do it right. Goltens

WORLDWIDE

Oslo (47-22) 68 90 80

Hong Kong (852) 7550161 • Dubai (971-4) 341642

Shanghai (86) 21 4811721 - Singapore (65) 8 61 52 20

Rotterdam (31 -10) 4 16 79 00 • Jakarta (6221) 640 8091

Wilmington, CA (310) 549-2550 • Miami, FL (305) 576-4410

Fairhaven, MA (508) 993-2631 • New York, NY (718) 855-7200

Circle 348 on Fleader Service Card

56

56

58

58