Page 42: of Maritime Reporter Magazine (October 1998)

Read this page in Pdf, Flash or Html5 edition of October 1998 Maritime Reporter Magazine

VESSEL FOCUS: TUGS & TOWBOATS

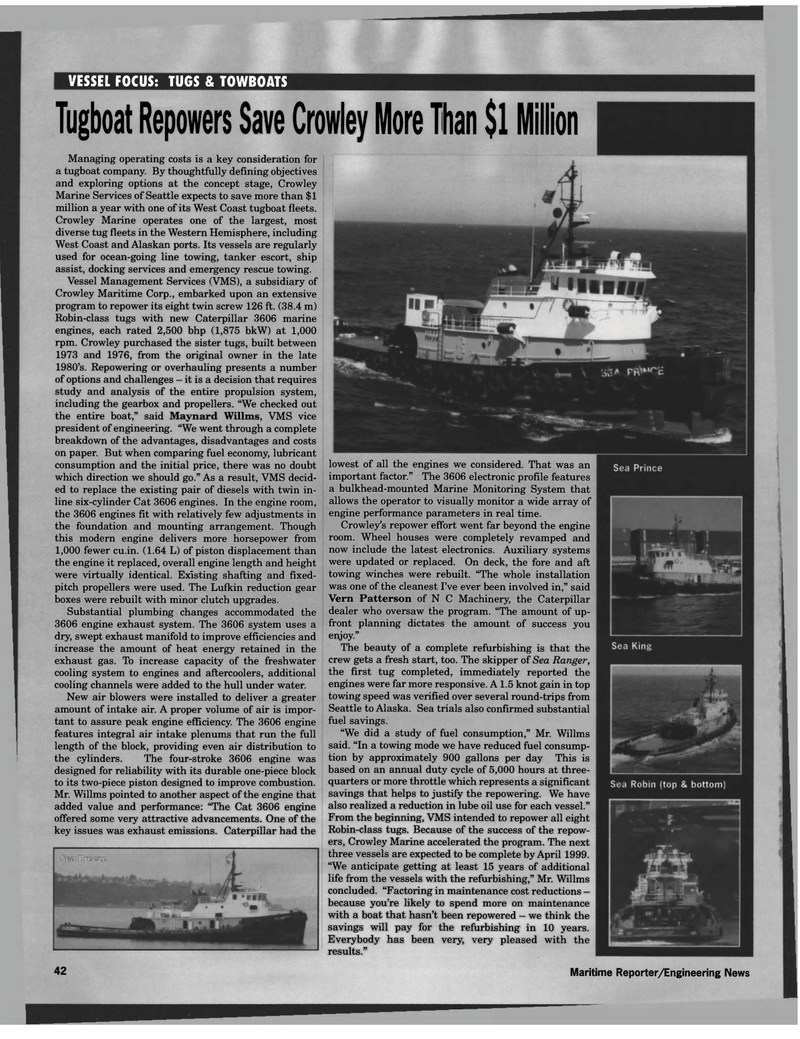

Tugboat Repowers Save Crowley More Than $1 Million lowest of all the engines we considered. That was an important factor." The 3606 electronic profile features a bulkhead-mounted Marine Monitoring System that allows the operator to visually monitor a wide array of engine performance parameters in real time.

Crowley's repower effort went far beyond the engine room. Wheel houses were completely revamped and now include the latest electronics. Auxiliary systems were updated or replaced. On deck, the fore and aft towing winches were rebuilt. "The whole installation was one of the cleanest I've ever been involved in," said

Vern Patterson of N C Machinery, the Caterpillar dealer who oversaw the program. "The amount of up- front planning dictates the amount of success you enjoy."

The beauty of a complete refurbishing is that the crew gets a fresh start, too. The skipper of Sea Ranger, the first tug completed, immediately reported the engines were far more responsive. A 1.5 knot gain in top towing speed was verified over several round-trips from

Seattle to Alaska. Sea trials also confirmed substantial fuel savings. "We did a study of fuel consumption," Mr. Willms said. "In a towing mode we have reduced fuel consump- tion by approximately 900 gallons per day This is based on an annual duty cycle of 5,000 hours at three- quarters or more throttle which represents a significant savings that helps to justify the repowering. We have also realized a reduction in lube oil use for each vessel."

From the beginning, VMS intended to repower all eight

Robin-class tugs. Because of the success of the repow- ers, Crowley Marine accelerated the program. The next three vessels are expected to be complete by April 1999. "We anticipate getting at least 15 years of additional life from the vessels with the refurbishing," Mr. Willms concluded. "Factoring in maintenance cost reductions - because you're likely to spend more on maintenance with a boat that hasn't been repowered - we think the savings will pay for the refurbishing in 10 years.

Everybody has been very, very pleased with the results."

Managing operating costs is a key consideration for a tugboat company. By thoughtfully defining objectives and exploring options at the concept stage, Crowley

Marine Services of Seattle expects to save more than $1 million a year with one of its West Coast tugboat fleets.

Crowley Marine operates one of the largest, most diverse tug fleets in the Western Hemisphere, including

West Coast and Alaskan ports. Its vessels are regularly used for ocean-going line towing, tanker escort, ship assist, docking services and emergency rescue towing.

Vessel Management Services (VMS), a subsidiary of

Crowley Maritime Corp., embarked upon an extensive program to repower its eight twin screw 126 ft. (38.4 m)

Robin-class tugs with new Caterpillar 3606 marine engines, each rated 2,500 bhp (1,875 bkW) at 1,000 rpm. Crowley purchased the sister tugs, built between 1973 and 1976, from the original owner in the late 1980's. Repowering or overhauling presents a number of options and challenges - it is a decision that requires study and analysis of the entire propulsion system, including the gearbox and propellers. "We checked out the entire boat," said Maynard Willms, VMS vice president of engineering. "We went through a complete breakdown of the advantages, disadvantages and costs on paper. But when comparing fuel economy, lubricant consumption and the initial price, there was no doubt which direction we should go." As a result, VMS decid- ed to replace the existing pair of diesels with twin in- line six-cylinder Cat 3606 engines. In the engine room, the 3606 engines fit with relatively few adjustments in the foundation and mounting arrangement. Though this modern engine delivers more horsepower from 1,000 fewer cu.in. (1.64 L) of piston displacement than the engine it replaced, overall engine length and height were virtually identical. Existing shafting and fixed- pitch propellers were used. The Lufkin reduction gear boxes were rebuilt with minor clutch upgrades.

Substantial plumbing changes accommodated the 3606 engine exhaust system. The 3606 system uses a dry, swept exhaust manifold to improve efficiencies and increase the amount of heat energy retained in the exhaust gas. To increase capacity of the freshwater cooling system to engines and aftercoolers, additional cooling channels were added to the hull under water.

New air blowers were installed to deliver a greater amount of intake air. A proper volume of air is impor- tant to assure peak engine efficiency. The 3606 engine features integral air intake plenums that run the full length of the block, providing even air distribution to the cylinders. The four-stroke 3606 engine was designed for reliability with its durable one-piece block to its two-piece piston designed to improve combustion.

Mr. Willms pointed to another aspect of the engine that added value and performance: "The Cat 3606 engine offered some very attractive advancements. One of the key issues was exhaust emissions. Caterpillar had the 42 Maritime Reporter/Engineering News

41

41

43

43