Page 64: of Maritime Reporter Magazine (April 2016)

The Offshore Annual

Read this page in Pdf, Flash or Html5 edition of April 2016 Maritime Reporter Magazine

HEAVY LIFTING: CRANES • WINCHES • ROPES

Agile Lifting System:

A Heavy-Lift Sling Fast?

Samson’s new AGILE heavy-lift syn- thetic sling offers unprecedented ad- vantages in offshore environments, including exacting length tolerances, reduced-line weight to lighten loads, and dramatically shorter lead times for production. Slings that used to take weeks to fabricate, can now be achieved in a matter of days. Scal- able from 50mt to 4000 mt, AGILE is the next generation of heavy-lifting slings, combining the best advantages of both roving and rope slings into hybrid design that’s competitively priced and easy to trust.

4100 Millennium

Crawler Crane

The Lampson 4100 Millennium

Crawler Crane combines the struc- tural integrity and versatility of the (Copyright: Statoil AS, Photo by Oyvind Hagen)

Manitowoc 4100 with the safety and

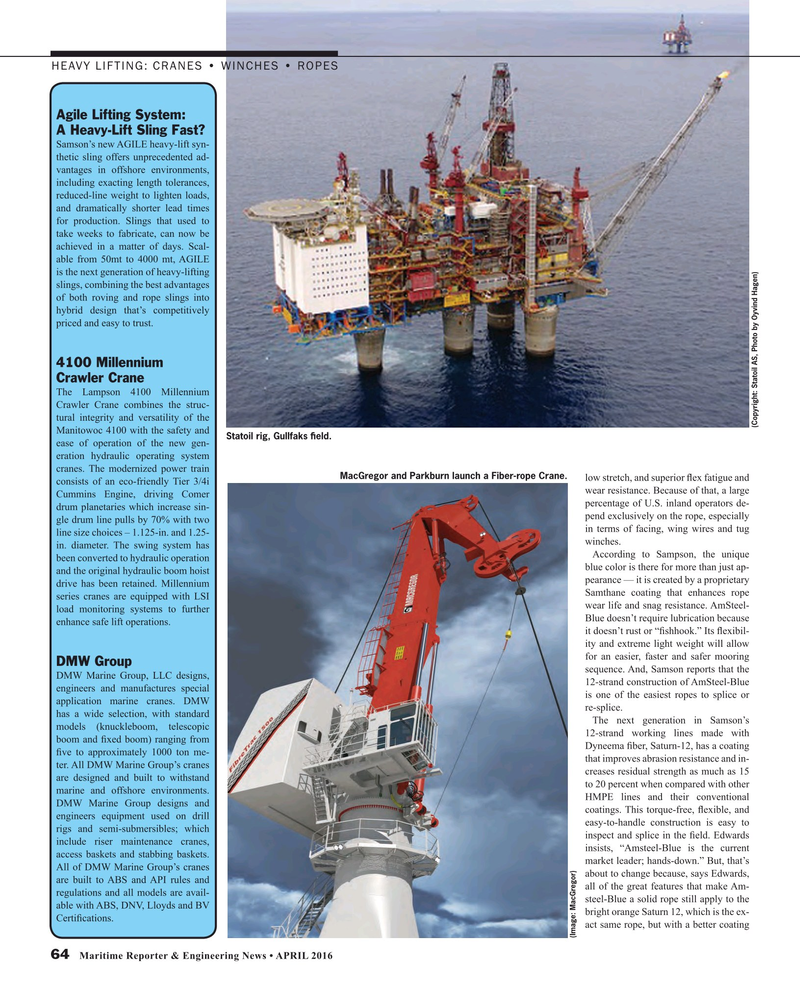

Statoil rig, Gullfaks ? eld.

ease of operation of the new gen- eration hydraulic operating system cranes. The modernized power train

MacGregor and Parkburn launch a Fiber-rope Crane.

low stretch, and superior ? ex fatigue and consists of an eco-friendly Tier 3/4i wear resistance. Because of that, a large

Cummins Engine, driving Comer percentage of U.S. inland operators de- drum planetaries which increase sin- pend exclusively on the rope, especially gle drum line pulls by 70% with two in terms of facing, wing wires and tug line size choices – 1.125-in. and 1.25- winches.

in. diameter. The swing system has

According to Sampson, the unique been converted to hydraulic operation blue color is there for more than just ap- and the original hydraulic boom hoist pearance — it is created by a proprietary drive has been retained. Millennium

Samthane coating that enhances rope series cranes are equipped with LSI wear life and snag resistance. AmSteel- load monitoring systems to further

Blue doesn’t require lubrication because enhance safe lift operations.

it doesn’t rust or “? shhook.” Its ? exibil- ity and extreme light weight will allow for an easier, faster and safer mooring

DMW Group sequence. And, Samson reports that the

DMW Marine Group, LLC designs, 12-strand construction of AmSteel-Blue engineers and manufactures special is one of the easiest ropes to splice or application marine cranes. DMW re-splice. has a wide selection, with standard

The next generation in Samson’s models (knuckleboom, telescopic 12-strand working lines made with boom and ? xed boom) ranging from

Dyneema ? ber, Saturn-12, has a coating ? ve to approximately 1000 ton me- that improves abrasion resistance and in- ter. All DMW Marine Group’s cranes creases residual strength as much as 15 are designed and built to withstand to 20 percent when compared with other marine and offshore environments.

HMPE lines and their conventional

DMW Marine Group designs and coatings. This torque-free, ? exible, and engineers equipment used on drill easy-to-handle construction is easy to rigs and semi-submersibles; which inspect and splice in the ? eld. Edwards include riser maintenance cranes, insists, “Amsteel-Blue is the current access baskets and stabbing baskets. market leader; hands-down.” But, that’s

All of DMW Marine Group’s cranes about to change because, says Edwards, are built to ABS and API rules and all of the great features that make Am- regulations and all models are avail- steel-Blue a solid rope still apply to the able with ABS, DNV, Lloyds and BV bright orange Saturn 12, which is the ex-

Certi? cations.

act same rope, but with a better coating (Image: MacGregor) 64 Maritime Reporter & Engineering News • APRIL 2016

MR #4 (58-65).indd 64 4/8/2016 10:45:01 AM

63

63

65

65