Page 68: of Maritime Reporter Magazine (November 2020)

Workboat Edition

Read this page in Pdf, Flash or Html5 edition of November 2020 Maritime Reporter Magazine

SHAFT LINE SOLUTIONS

Wärtsilä Airguard (Two Pipe) System

Introduced in 1998, the Wärtsilä Airguard seal has proven itself in the marine industry for its robustness and reliability. The company recently debuted the Wärtsilä Airguard Two-Pipe

System. Panu Sorvisto, Sales Director, Shaft Line Solutions, explains the signi? cance.

By Greg Trauthwein n line with the full maritime prod- lubrication and cooling. Looking at the solution,” said Sorvisto. While the orig- uct and service portfolio from system holistically for vessel owners inal solution has a strong track record

Wärtsilä, shaft line solutions are mulling a shaft seal upgrade, key points over more than two decades, he said offered not simply from the sin- for the new system include: it had piping con? gurations, which in gle product focus, rather through • Reduced piping arrangement to some retro? ts and upgrades was not op-

I the spectrum of a solution package that help lower installation costs; timal because of the need to often work is intended to deliver ef? ciencies and • No requirement to remove stern on the vessel piping system throughout cost-effectiveness to shipowners tube for installation or retro? t; the stern tube.

With this as a backdrop, Wärtsilä – via • An innovative oil circulator to im- “We had cases where our customers extensive R&D – offers a new shaft seal prove seal security; and approached us to upgrade their sealing solution based on the Wärtsilä Airguard • A streamlined auxiliary system to system to the Airguard system,” but product technology, a solution designed reduce required space in the engine when we discussed the modi? cations to offer vessel owners a way to upgrade room. needed, “a good number of them said, shaft seals in a lean and cost-ef? cient “The ? rst Airguard solution came out ‘well, it’s too big job to execute during way. because there was a need from the mar- the normal drydocking so we’ll skip it

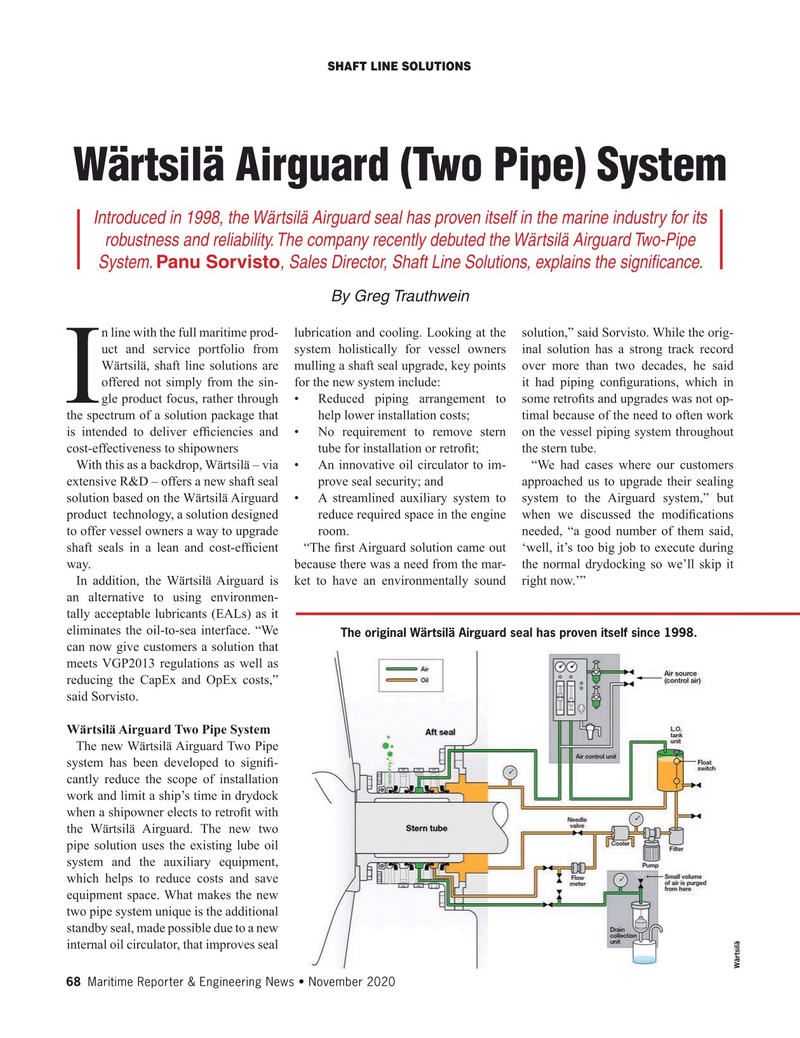

In addition, the Wärtsilä Airguard is ket to have an environmentally sound right now.’” an alternative to using environmen- tally acceptable lubricants (EALs) as it eliminates the oil-to-sea interface. “We

The original Wärtsilä Airguard seal has proven itself since 1998.

can now give customers a solution that meets VGP2013 regulations as well as reducing the CapEx and OpEx costs,” said Sorvisto.

Wärtsilä Airguard Two Pipe System

The new Wärtsilä Airguard Two Pipe system has been developed to signi? - cantly reduce the scope of installation work and limit a ship’s time in drydock when a shipowner elects to retro? t with the Wärtsilä Airguard. The new two pipe solution uses the existing lube oil system and the auxiliary equipment, which helps to reduce costs and save equipment space. What makes the new two pipe system unique is the additional standby seal, made possible due to a new internal oil circulator, that improves seal

Wärtsilä 68 Maritime Reporter & Engineering News • November 2020

MR #11 (66-74).indd 68 11/9/2020 1:58:29 PM

67

67

69

69