Page 69: of Maritime Reporter Magazine (November 2020)

Workboat Edition

Read this page in Pdf, Flash or Html5 edition of November 2020 Maritime Reporter Magazine

SHAFT LINE SOLUTIONS

For more in-depth coverage, watch Panu

Sorvisto, Sales Director, Shaft Line Solu- tions, Wärtsilä, on Maritime Reporter

TV: bit.ly/3oZf4Pc

With this feedback in hand, Wärtsilä to avoid the tail shaft removal because ro? tting of the seals,” said Sorvisto. went back to the drawing board with its that comes with that cost, it comes with “We are talking about existing vessels, engineering team to devise a solution extended docking time in some cases,” where the engine room is full of all dif- that required signi? cantly less work and said Sorvisto. “So for most of the in- ferent equipment and auxiliaries. Put- time in drydock to install the Airguard stallations where we have a two-pipe ting new auxiliaries into the existing solution. system, there is no need for tail shaft engine room is always a challenge. So “We have plenty of brilliant engi- removal provided that the piping system with this new two-pipe airguard sys- neers,” said Sorvisto, so they put their ful? lls a certain criteria. That is a clear tem, we have managed to reduce the heads together and started to think of a bene? t.” number of the auxiliaries,” which also better solution. “The outcome was the In addition to eased installation requir- comes with bene? ts, including less time two pipe solution.” ing less time (and money) in drydock, for installation and less required space

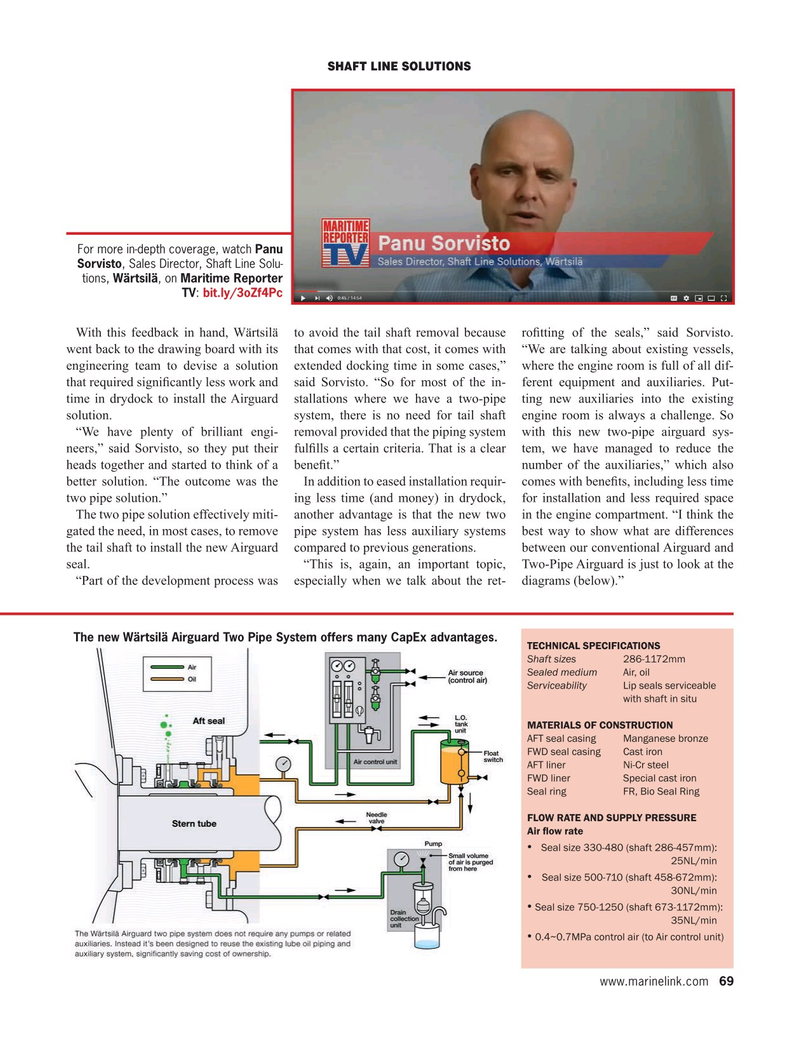

The two pipe solution effectively miti- another advantage is that the new two in the engine compartment. “I think the gated the need, in most cases, to remove pipe system has less auxiliary systems best way to show what are differences the tail shaft to install the new Airguard compared to previous generations. between our conventional Airguard and seal. “This is, again, an important topic, Two-Pipe Airguard is just to look at the “Part of the development process was especially when we talk about the ret- diagrams (below).”

The new Wärtsilä Airguard Two Pipe System offers many CapEx advantages.

TECHNICAL SPECIFICATIONS

Shaft sizes 286-1172mm

Sealed medium Air, oil

Serviceability Lip seals serviceable with shaft in situ

MATERIALS OF CONSTRUCTION

AFT seal casing Manganese bronze

FWD seal casing Cast iron

AFT liner Ni-Cr steel

FWD liner Special cast iron

Seal ring FR, Bio Seal Ring

FLOW RATE AND SUPPLY PRESSURE

Air ? ow rate •

Seal size 330-480 (shaft 286-457mm): 25NL/min •

Seal size 500-710 (shaft 458-672mm): 30NL/min •

Seal size 750-1250 (shaft 673-1172mm): 35NL/min • 0.4~0.7MPa control air (to Air control unit) www.marinelink.com 69

MR #11 (66-74).indd 69 11/9/2020 6:28:01 PM

68

68

70

70