Page 56: of Maritime Reporter Magazine (September 2023)

Marine Design Edition

Read this page in Pdf, Flash or Html5 edition of September 2023 Maritime Reporter Magazine

TECH FOCUS: WELDING time, labor, and inputs. A change or upgrade in welding machines could allow thicker materi- als to be used without any edge preparation at all!

Heat Treatment

Some alloys or material thicknesses require heat treatment either before or after the weld is made. This heat treatment stage could be as simple as preheating the joint a certain amount above ambient temperature, up to a complex multistage post weld heat treatment that occurs over multiple days. Any of these activities add time and cost to the welding operation. Taking

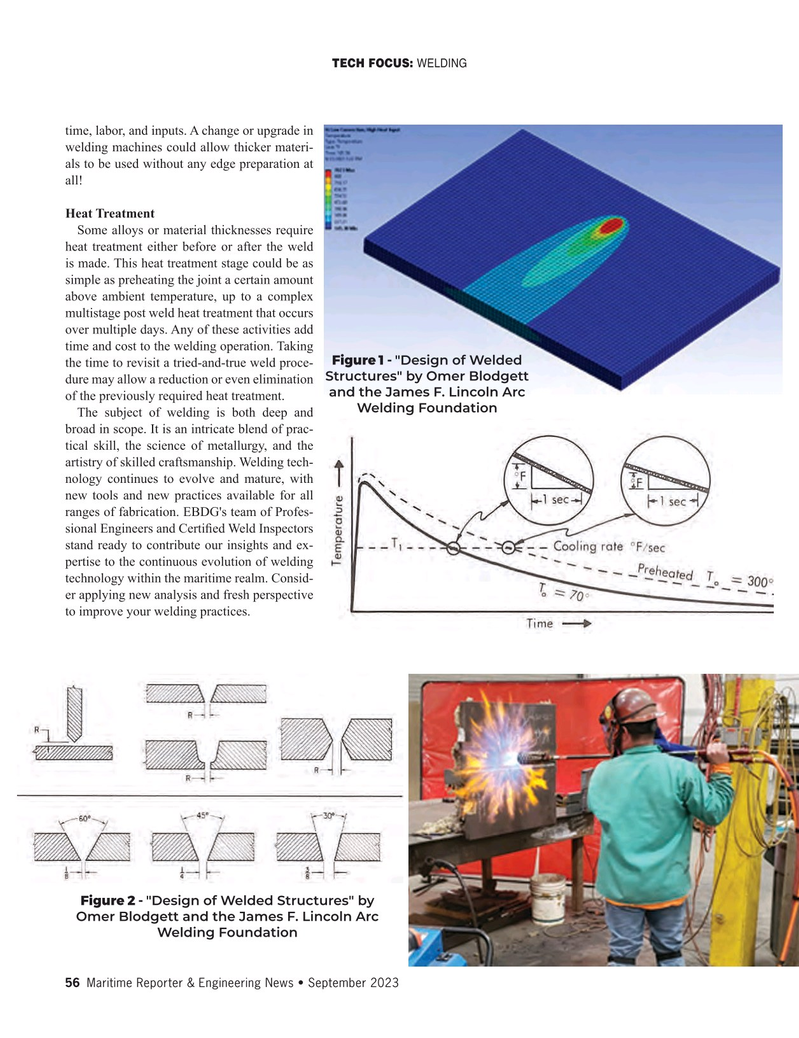

Figure 1 - "Design of Welded the time to revisit a tried-and-true weld proce- dure may allow a reduction or even elimination Structures" by Omer Blodgett and the James F. Lincoln Arc of the previously required heat treatment.

Welding Foundation

The subject of welding is both deep and broad in scope. It is an intricate blend of prac- tical skill, the science of metallurgy, and the artistry of skilled craftsmanship. Welding tech- nology continues to evolve and mature, with new tools and new practices available for all ranges of fabrication. EBDG's team of Profes- sional Engineers and Certi? ed Weld Inspectors stand ready to contribute our insights and ex- pertise to the continuous evolution of welding technology within the maritime realm. Consid- er applying new analysis and fresh perspective to improve your welding practices.

Figure 2 - "Design of Welded Structures" by

Omer Blodgett and the James F. Lincoln Arc

Welding Foundation 56 Maritime Reporter & Engineering News • September 2023

MR #9 (50-60).indd 56 9/7/2023 10:45:33 AM

55

55

57

57