Decoupled Riser Systems

-

- Reviewing Sapinhoá-Lula NE BSR System Marine Technology, Sep 2018 #18

The exploration and production of deepwater pre-salt plays offshore Brazil have triggered major technological challenges. Some reservoirs are located under 2,000 meters of water and have to be drilled through another 2,000 or so meters of salt. Although exploration challenges have been daunting, production challenges are no less formidable. With a number of production and injection wells placed over the large reservoirs, the difficulty of reliably and safely bringing the oil and gas to production FPSOs have been compounded by the extreme water depths involved.

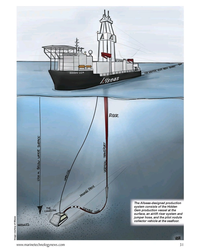

In 2011 Subsea 7 was awarded a milestone subsea umbilical, riser and flowline (SURF) contract by national operator Petrobras for four decoupled riser systems to be installed in the Sapinhoá-Lula NE fields located in the Santos Basin, in the largest engineering, procurement, installation and commissioning (EPIC) SURF contract awarded to date in Brazil. The pioneering technology for connecting a large number of wells to a single FPSO was developed by the Petrobras’ research center (Cenpes) and Subsea 7, with the support of UFRJ (Federal University of Rio de Janeiro) and USP (University of São Paulo). The project required the installation of four huge 2,800ton submerged buoys approximately 250 meters below the surface. The system was designed to accommodate a combination of 45 risers/umbilicals for each field in a small area in a decoupled arrangement. Subsea 7’s scope was specifically 27 3.9km steel catenary risers of which 18 were 7.5-inch production lines, three 9.5-inch water injection lines and six 8-inch gas injection lines.

Buoy Supported Risers (BSR)

Petrobras and its partners selected the Buoy Supported Risers (BSR) system as the most effective solution for the project. Ivan Cruz, Senior Product Manager at Subsea 7, explained that in order to achieve the system’s performance and installation requirements, various innovative technologies were applied. The creation of the Angular Connection Module (ACM) proved integral to the BSR system by connecting the flexible jumpers to the pre-installed buoys. With the large number of risers installed, the buoys can take up different positions and the ACM allows connections to be made at misaligned angles of up to 15°, reliably and safely, reducing offshore hook-up time. Within the BSR system the introduction of the ACM reduced fluid flow to a single interfacing point, thereby decreasing cost and enhancing reliability by eliminating further potential leak paths.The main requirement for successful BSR mooring was to use tether adjustments to stabilize and position each buoy. The main challenge associated here was the selection of an appropriate tether material, helping to ensure that the axial stiffness was preferred in order to balance the desired tension adjustment, and to keep adjacent tethers closely together while controlling the initial slackening during fabrication and installation. Although steel air filled pipe is a commonly used material for Tension Leg Platforms (TLPs), a moderated decrease in the axial stiffness was preferred, this allowed for a simple top tension between adjacent tethers and length adjustments. A significant increase in tendon stretch, applied while the BSR was in vertical motion, would not have been an acceptable approach because of the high possibility of misalignment and damage to the system.

Another equally important technical issue which needed to be addressed was the submerged tether weight, that had the potential to minimize the impact on negative buoyancy and dimensions. Sheathed spiral strand wires (SSW) were finally chosen because the sheathed spiral strand wire has a long track record in other mooring systems and was found to meet all the requirements for 27 years of service life. The stretch is not excessive, but is enough to help minimize the effects of length measurement tolerances, being simpler to install offshore, including the locking of the lines in the connectors at the required point.

Deepwater Challenges

The development of the Sapinhoá-Lula NE reservoirs were major technological challenges. The innovative BSR concept was a unique design in the industry at the time and helped reduce the FPSO riser motions to a very minimal level. With this configuration, the movements of the floating platform are not transferred integrally to the rigid risers, reducing the damage because of the fatigue and guaranteeing their useful life even in severe meteoceanographic conditions. According to Ricardo Francis, consultant of the Management of Technology of Pipes and Risers at Cenpes, the buoys together are responsible for the production of 240,000 barrels of oil per day. “We studied a buoy system to take the dynamics of rigid lines because they internally have a coating that prevents corrosion of the steel due to the presence of gases such as H2S and CO2 and this coating has a more demanding calculation procedure, with the presence of the buoy, the useful life of these lines has increased considerably, making production feasible in the pre-salt fields. From there, flexible lines, called jumpers, are placed that connect the buoy to the production platform. In addition to bringing production to the PEUs, it is intended to absorb their dynamic movements. This is the main idea of the BSR,” he says.With the buoy holding the pipes that conduct the oil and gas from the well on the seabed to the FPSO, it relieves the load applied to the platform. Another advantage is to allow the installation of the risers even before the arrival of the production platform. “The economic advantage was the anticipation of production. If you prepare everything before you get to the production unit it simply connects the risers and you can anticipate 3 to 6 months of production,” says Ricardo. Although there were teething problems in the installation of the first BSR, which led to delays in this first installation, the operators are adamant that the system has been working smoothly and with no major problems since it started operations in 2014 and that similar systems may be used in other deepwater pre-salt plays in future.

A look at some of the Technological Challenges associated to the BSR system:

- An efficient method to install corrosion resistant alloy (CRA) mechanically lined BuBi pipe by the reeled-lay installation method;

- The development of the Angular Connection Module (ACM). This unique engineering capability greatly simplified buoy hardware by minimizing the number of connections and potential leak paths;

- A fit for purpose 400 ton tension capable riser installation tool, allowing for the reliable deployment of 27 SCRs;

- A state-of-the-art fracture mechanics engineering assessment for plastically strained pipe joints made of alloy 625 welds;

- A novel tethered tensioned mooring system, similar to that for Tension Leg Platforms (TLPs), but using spiral strand cables and chains for installation simplicity and to achieve the necessary dynamic performance;

- A tether based tensioning system capable of withstanding top angle variations associated with the buoys natural offsets and the potential length variations of the almost two kilometers long tethers;

- A bottom connector device to simplify connections to foundations. The combined result of all these innovations, some incremental and resulting from existing technologies, and others entirely new and breakthrough, gave rise to the complete BSR system, which has been vital in maintaining the production rates and low downtime for the two reservoirs.

-

- Brazil Offshore: Petrobras & Subsea Engineering Marine Technology, Nov 2013 #34

to date is the largest EPIC-SURF contract awarded in Brazil. The project scope includes the subsea engineering and the subsea installation of four decoupled riser systems featuring large submerged buoys supporting 27 steel catenary risers. The engineering and project management work is ongoing at Subsea 7’s

-

)

March 2024 - Marine Technology Reporter page: 4th Cover

)

March 2024 - Marine Technology Reporter page: 4th CoverGlow a little longer. Superior sensor performance on a rmance on a – – RBRtridentfraction of the power RBRtridente teee ackscatter or turbidity with hi i in n n t t th h h he e e s sa a am m m me Measure chlorophyll a, fDOM, and backscatter or turbidity within the same e e sensor package using the

-

)

March 2024 - Marine Technology Reporter page: 48

)

March 2024 - Marine Technology Reporter page: 48Index page MTR MarApr2024:MTR Layouts 4/4/2024 3:19 PM Page 1 Advertiser Index PageCompany Website Phone# 17 . . . . .Airmar Technology Corporation . . . . . . . . . .www.airmar.com . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .(603) 673-9570 9 . . . . . .Birns, Inc. . . . . . . . . . .

-

)

March 2024 - Marine Technology Reporter page: 45

)

March 2024 - Marine Technology Reporter page: 45ronments. The new agreement will address speci? c techni- cal gaps in the UUV defense and offshore energy markets especially for long duration, multi-payload mission opera- tions where communications are often denied or restricted. As part of the new alliance, Metron’s Resilient Mission Autonomy portfolio

-

)

March 2024 - Marine Technology Reporter page: 44

)

March 2024 - Marine Technology Reporter page: 44NEW TECH OCEANOLOGY INTERNATIONAL 2024 Image courtesy Metron/Cellula Teledyne Marine acquires Valeport: Matt Quartley, MD, Valeport and Ole Søe-Pedersen, VP & Image courtesy Teledyne Marine GM Teledyne Marine announce the deal in London. Pictured (L-R): Cellula Robotics, President, Eric Jackson, Metron

-

)

March 2024 - Marine Technology Reporter page: 43

)

March 2024 - Marine Technology Reporter page: 43Image courtesy Kongsberg Discovery Image courtesy Teledyne Marine New Products Teledyne Marine had its traditional mega-booth at Oi, busy start to ? nish. Image courtesy Greg Trauthwein offers quality sub-bottom pro? ling capability without the need tion of offshore windfarms. GeoPulse 2 introduces new

-

)

March 2024 - Marine Technology Reporter page: 42

)

March 2024 - Marine Technology Reporter page: 42NEW TECH OCEANOLOGY INTERNATIONAL 2024 Image courtesy Greg Trauthwein Image courtesy BIRNS MacArtney launches the new ultra-compact ø12.7 mm SubConn Nano connector. Innovative connectivity built on 45 years of ? eld-proven and market-trusted design. Image courtesy MacArtney Birns celebrated its 70th

-

)

March 2024 - Marine Technology Reporter page: 41

)

March 2024 - Marine Technology Reporter page: 41Image courtesy Outland Technology Image courtesy Exail Image courtesy Submaris and EvoLogics Vehicles The ROV-1500 from Outland Technology represents a leap forward in underwater robotics, a compact remotely operated vehicle (ROV) weighing in at less than 40 lbs (19kg) the ROV- 1500 is easy to transport

-

)

March 2024 - Marine Technology Reporter page: 40

)

March 2024 - Marine Technology Reporter page: 40NEW TECH OCEANOLOGY INTERNATIONAL 2024 All photos courtesy MTR unless otherwise noted NEW TECH, PARTNERSHIPS LAUNCH IN LONDON With Oceanology International now one month in the rear-view mirror, MTR takes a look at some of the interesting technologies launched before, during and after the London event.

-

)

March 2024 - Marine Technology Reporter page: 39

)

March 2024 - Marine Technology Reporter page: 39Photo courtesy Global Ocean Design Figure 7 A 35Ah AGM lead-acid battery is tested using the West Mountain Radio CBA to show the effect of simply ? lling the battery voids with mineral oil as a compensating ? uid. The CBA is programmed to cut-off at a voltage of 10.50v. The top line (red) shows the

-

)

March 2024 - Marine Technology Reporter page: 38

)

March 2024 - Marine Technology Reporter page: 38LANDER LAB #10 Photo courtesy West Mountain Radio Photo courtesy of Clarios/AutoBatteries.com Figure 6 The West Mountain Radio Computerized Battery Analyzer (CBA V) attaches to a Figure 5 laptop by a USB-B cable, and to a battery by Powerpole® Connectors. Exploded view of an AGM lead-acid battery.

-

)

March 2024 - Marine Technology Reporter page: 37

)

March 2024 - Marine Technology Reporter page: 37miscible barrier ? uid heavier than seawater (sg=1.026) and lighter than the battery electrolyte (sg=1.265). The original cell vent cap was screwed into the top of the riser pipe to vent the gases associated with charging. Wires were soldered to the lead (Pb) posts. The lead-acid battery was additionall

-

)

March 2024 - Marine Technology Reporter page: 36

)

March 2024 - Marine Technology Reporter page: 36LANDER LAB #10 Of special interest for marine applications, LiPo batteries are Shipping any kind of lithium battery can be a challenge, and offered in a “pouch” design, with a soft, ? at body. The pouch IATA regs vary with the batteries inside or outside an instru- is vacuum-sealed, with all voids ?

-

)

March 2024 - Marine Technology Reporter page: 33

)

March 2024 - Marine Technology Reporter page: 33regulated industry in the world.” How- ever, commercial success depends on many factors, not least a predictable OPEX. Over the past four years, SMD has worked with Oil States Industries to calculate cost per tonne ? gures for prospective customers. Patania II uses jet water pumps to Oil States’

-

)

March 2024 - Marine Technology Reporter page: 32

)

March 2024 - Marine Technology Reporter page: 32FEATURE SEABED MINING by a sea? oor plume from its pilot collection system test. pact, nodule collection system that utilizes mechanical and The Metals Company recently signed a binding MoU with hydraulic technology. Paci? c Metals Corporation of Japan for a feasibility study on The company’s SMD

-

)

March 2024 - Marine Technology Reporter page: 31

)

March 2024 - Marine Technology Reporter page: 31The Allseas-designed production system consists of the Hidden Gem production vessel at the surface, an airlift riser system and jumper hose, and the pilot nodule collector vehicle at the sea? oor. Image courtesy of Allseas www.marinetechnologynews.com 31 MTR #3 (18-33).indd 31 4/4/2024 2:12:41

-

)

March 2024 - Marine Technology Reporter page: 30

)

March 2024 - Marine Technology Reporter page: 30FEATURE SEABED MINING bilical. It has passive heave compensation which nulli? es the necott. “The focus since then has been on scaling while en- wave, current and vessel motions that in? uence loads in the suring the lightest environmental impact,” says The Metals power umbilical. The LARS can

-

)

March 2024 - Marine Technology Reporter page: 29

)

March 2024 - Marine Technology Reporter page: 29n January, Norway said “yes” to sea- bed mining, adding its weight to the momentum that is likely to override the calls for a moratorium by over 20 countries and companies such as I Google, BMW, Volvo and Samsung. Those against mining aim to protect the unique and largely unknown ecology of the sea?

-

)

March 2024 - Marine Technology Reporter page: 25

)

March 2024 - Marine Technology Reporter page: 25Auerbach explained that ideally, “one ? ed layers of geothermal activity,” noted changes over an area of 8,000 km2. They would have both instruments: seismom- Skett, “and the change in salinity and dis- found up to seven km3 of displaced ma- eters to detect and locate subsurface ac- solved particles for

-

)

March 2024 - Marine Technology Reporter page: 19

)

March 2024 - Marine Technology Reporter page: 19About the Author vey with the pipe tracker is not required, resulting in signi? - Svenn Magen Wigen is a Cathodic Protection and corrosion control cant cost savings, mainly related to vessel charter. expert having worked across The major advantage of using FiGS on any type of subsea engineering, design

-

)

March 2024 - Marine Technology Reporter page: 18

)

March 2024 - Marine Technology Reporter page: 18TECH FEATURE IMR There are also weaknesses in terms of accuracy because of FiGS Operations and Bene? ts signal noise and the ability to detect small ? eld gradients. In Conventional approaches to evaluating cathodic protection this process there is a risk that possible issues like coating (CP)

-

)

March 2024 - Marine Technology Reporter page: 17

)

March 2024 - Marine Technology Reporter page: 17• Integrity assessment, and otherwise covered, e.g., by rock dump. As for depletion of • Mitigation, intervention and repair. sacri? cial anodes, this can be dif? cult or even impossible to Selecting the best method for collecting the data these work- estimate due to poor visibility, the presence of

-

)

March 2024 - Marine Technology Reporter page: 15

)

March 2024 - Marine Technology Reporter page: 15sensor options for longer mission periods. About the Author For glider users working in ? sheries and conservation, Shea Quinn is the Product Line Manager the Sentinel can run several high-energy passive and active of the Slocum Glider at Teledyne Webb acoustic sensors, on-board processing, and imaging

-

)

March 2024 - Marine Technology Reporter page: 11

)

March 2024 - Marine Technology Reporter page: 11assist in identifying mines and act as a neutralization device. About the Author Bottom mines pose even greater chal- David R. Strachan is a defense analyst and founder of lenges. Unlike contact mines, bottom Strikepod Systems, a research and strategic advisory mines utilize a range of sensors to

-

)

March 2024 - Marine Technology Reporter page: 9

)

March 2024 - Marine Technology Reporter page: 9from marinas along the western coast. The exact number of lizing laser detection systems can detect mines just below the mines, as well as their locations, remains largely a mystery, surface, even those hiding in murky water. The Airborne Laser although reports suggest that over three hundred have been