Page 36: of Marine News Magazine (June 1969)

Read this page in Pdf, Flash or Html5 edition of June 1969 Marine News Magazine

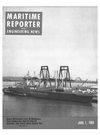

There Is More Than One Way To Do A Job A unique "teeter-totter" method, devised by the rigging department foreman at Beth-lehem Steel Corporation's San Francisco shipyard, was employed to unstep the 105-foot-long digging ladder on the hydraulic suction dredge Franciscan. The dredge is shown on drydock at the yard before the ladder was unhinged and sponsons welded to the hull. An ingenious "teeter-totter" method for unstepping a 360-ton digging ladder was developed at Bethlehem Steel Corporation's San Francisco shipyard during recent overhaul and modification work on the dredge Franciscan. The huge hydraulic suction dredge draws bottom sand or mud through a 30-inch-diameter pipe which runs from the end of the 105-foot-long digging ladder through the hull and out the stern. Owned by the Utah Construction and Min-ing Co. of San Francisco, the Fran-ciscan is one of the largest such vessels on the Pacific Coast. Two years ago, in preparation for an ex-tensive San Francisco bay bottom dredging job, the Bethlehem yard lengthened the ladder from 78 to 105 feet. When the dredge arrived at the yard for its latest overhaul in De-cember of last year, it was decided to unstep the ladder in order to inspect the trunnion (hinge) pins and bushings. Although removal of the cutter head and some of the suction pipe had reduced the weight of the lad-der to approximately 330 tons, it was still far too heavy to be lifted by the 50-ton dock crane that nor-mally serves the drydock. Use of a derrick barge was discarded as being too costly. The " teeter-totter solution to the problem was finally arrived at by E. A. Bergeron, foreman of the yard's rigging department. "Why not provide an off-center fulcrum so that if the forward end of the ladder were lowered, the other end would raise itself out of the trun-nion bearings?," Mr. Bergeron rea-soned. His proposal was accepted by the dredge owners as being the most efficient and economical. The ladder, cribbed on 12-inch by 12-inch timbers which rose from the drydock floor to its underside. was lifted by its own hoisting tack-le high enough to install a rotating steel pipe. The pipe was placed five feet nine inches inboard from the center of gravity to act as a ful-crum. The dockside crane was then used to lower the outboard end of the ladder within six feet of the dock floor. This raised the after, or inboard, end of the ladder six feet out of the trunnion bearings. The two, 34-inch-diameter, 6.000-pound trunnion pins were then re-moved. Both bearings and pins were replaced after inspection. As part of the modification work. Bethlehem fabricated and installed two 180-foot-long sponsons. seven feet wide and 12 feet deep, in order to increase the Franciscan's buoy-ancy. One of these was then welded to each side of the dredge's hull. Besides miscellaneous overhaul items of a general nature, the 30-inch-diameter suction piping in the digging ladder was replaced. Her overhaul and modification com-plete. the Franciscan is now ready for the next dredging assignment. Dillingham Transfers Wilgus To New York Dillingham Corporation, Hono-lulu, announced that A. Wilgus, Portland, Ore., has been transferred to New York to head a new office for the corporation's maritime ac-tivities. Mr. Wilgus, for 17 years mari-time sales manager for Albina En-gine & Machine Works, Portland, has been selected by Dillingham, new owner of Albina, to open an office for the corporation in New-York City. The office will be titled Dillingham Corporation, Maritime Services Division, and will be lo-cated at 299 Park Avenue, New York, N.Y. Mr. Wilgus, a steamship man be-fore joining Albina. has been active in the Portland Merchants Ex-change, World Trade Club. Pro-peller Club, and Portland Shipping Club. Replacing Mr. Wilgus as sales representative at Albina Engine & Machine Works will be William Wilson, veteran steamshipman, whose background includes Luck-enbach Steamship Co. and more recently, Calmar Steamship Cor-poration. Todd Reports Rise In Sales And Earnings Todd Shipyards Corporation, New York, N.Y., has reported for the year ended March 31, 1969, sales of $216,400,000 and net in-come of $5,265,000 equivalent to $3.56 per share. This compares with $194,100,000 sales and $4,930,000 net income or $3.38 per share in the previous year. Earnings for the cur-rent year are after providing $0.28 per share for the federal tax sur-charge. J. T. Gilbride, president, in re-leasing the figures attributed the increase in volume to several large conversion contracts completed during the year and to acceleration in new construction work. The board of directors declared a dividend of 30^ per share, payable June 16 to stockholders of record June 9, 1969. B&W Awards License To Chilean Shipyard For Diesel Repairs Burmeister & Wain of Copen-hagen, Denmark, entered into a service agreement with the Chilean shipyard Astilleros y Maestranzas de la Armada, ASMAR, in Valpa-raiso who have been conferred the rights to act as a B&W licensed repair shop and approved spare parts supplier. ASMAR is the thirteenth com-pany to join the Burmeister & Wain service organization, the aim of which is to offer the best pos-sible service throughout the world for ships equipped with B&W die-sel engines. ASMAR has three yards on the Chilean coast; the largest and most important is situ-ated at Talcahuano, the facilities at Valparaiso and Punta Arenas be-ing of minor importance. Talcahu-ano is one of the regular ports of call for shipping along the Pacific Coast of South America and is the terminal port for most shipping lines engaged in this trade. As there are also a number of vessels with B&W engines sailing under Chilean colors, the new B&W serv-ice station is well placed strate-gically. The agreement includes repair and service as well as the delivery of spare parts for B&W main and auxiliary engines installed in ships registered in Chile or those which dock for repairs in Chile. The spare parts will either be delivered from Burmeister & Wain in Copenhagen or be manufactured by ASMAR in its own workshops from B&W's drawings and in close cooperation with B&W's technical depart-ments. 47 Of 49 Nations Subsidize Shipping Andrew E. Gibson, Maritime Administrator, has released a com-prehensive study on "Maritime Subsidies" indicating that 47 out of 49 maritime nations give govern-ment assistance to their shipping and shipbuilding industries. Direct and indirect government aids granted by countries having fleets of 50,000 gross tons or more include operating and construc-tion subsidies, trade-in allowances, loans at low interest rates, interest subsidies, credit guarantees, ac-celerated depreciation, tax-free re-serve funds, duty-free imports on ship construction materials, cargo preference, and cabotage. "This study clearly indicates the type of competition with which the United States merchant marine must deal," Mr. Gibson commented, "and emphasizes the importance which maritime nations accord to the maintenance of their merchant fleets." > JEFFBOAT-BUILT FERRY for the state of Alaska was christened recently the E. L. Bart-lett in ceremonies in Jeffersonville, Ind. The oceangoing passenger and vehicle ferry is named for the late Senator E. L. Bartlett of Alaska. Mrs. E. L. Bortlett was the vessel's sponsor. In attendance for the christening were Governor and Mrs. Keith Miller from Alaska and Indiana Governor and Mrs. Edgar Whitcomb. After the ceremonies, the $2.5-million vessel was open to the public for inspection. 38 Maritime Reporter/Engineering News

35

35

37

37