Page 13: of Marine News Magazine (June 2005)

Read this page in Pdf, Flash or Html5 edition of June 2005 Marine News Magazine

June, 2005 • MarineNews 13

Circle 235 on Reader Service Card

NEWS

By Larry Pearson

There has been an interesting conver- gence of technology and market opportu- nity that is shaping the design of supply vessels serving the offshore drill rigs and platforms in the Gulf of Mexico (GOM).

Both of these forces spotlight the need for supply vessels to carry more liquid mud.

Liquid mud is essential in drilling bore holes in the earth. It is a liquid with con- siderable suspended solids and the liquids can be either oil or water based.

Drilling operations need so much more mud for basically two reasons: The increased drilling of wells in deepwater and the incentives offered by the Minerals

Management Service (MMS) to drill very deep wells (over 15,000 feet) in shallow water fields that already had their hydro- carbons extracted at lesser depths.

Faced with the demand for as much as 100,000 barrels of liquid mud per "spud- ded" well, the offshore vessel operators have been literally working overtime to develop a vessel capable of holding mas- sive amounts of liquid mud at a reason- able cost.

Hornbeck Offshore Services has devel- oped a plan for a high capacity mud ves- sel far exceeding what is currently avail- able. Their answer is to take a pair of existing sulfur tankers and convert them to haul at least twice as much mud as can be carried on any vessel serving the GOM at the present time.

Not only will these vessels haul large amount of mud they can support ROV operations as well as construction and other subsea tasks. Cost is expected to be $55-60 million per vessel.

In 2001, Hornbeck purchased the Ener- gy Service 9001 from Freeport-

McMoRan Sulphur. Recently they pur- chased a sister ship Benno C. Schmidt from a private owner.

Both vessels are 395 ft. by 72 ft. with a 25-ft. deep hull. The sulfur tankers make attractive conversion candidates since the specific gravity of the sulfur product they carried is similar to that of liquid mud.

Sulfur is mined on the top of salt domes in

GOM.

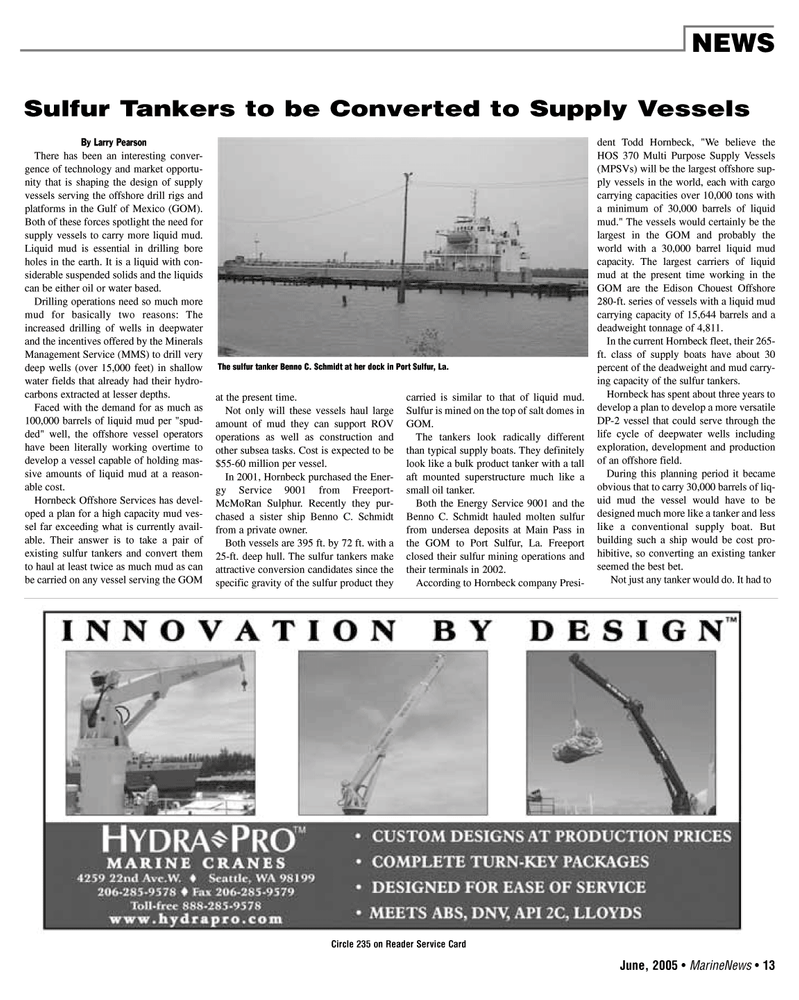

The tankers look radically different than typical supply boats. They definitely look like a bulk product tanker with a tall aft mounted superstructure much like a small oil tanker.

Both the Energy Service 9001 and the

Benno C. Schmidt hauled molten sulfur from undersea deposits at Main Pass in the GOM to Port Sulfur, La. Freeport closed their sulfur mining operations and their terminals in 2002.

According to Hornbeck company Presi- dent Todd Hornbeck, "We believe the

HOS 370 Multi Purpose Supply Vessels (MPSVs) will be the largest offshore sup- ply vessels in the world, each with cargo carrying capacities over 10,000 tons with a minimum of 30,000 barrels of liquid mud." The vessels would certainly be the largest in the GOM and probably the world with a 30,000 barrel liquid mud capacity. The largest carriers of liquid mud at the present time working in the

GOM are the Edison Chouest Offshore 280-ft. series of vessels with a liquid mud carrying capacity of 15,644 barrels and a deadweight tonnage of 4,811.

In the current Hornbeck fleet, their 265- ft. class of supply boats have about 30 percent of the deadweight and mud carry- ing capacity of the sulfur tankers.

Hornbeck has spent about three years to develop a plan to develop a more versatile

DP-2 vessel that could serve through the life cycle of deepwater wells including exploration, development and production of an offshore field.

During this planning period it became obvious that to carry 30,000 barrels of liq- uid mud the vessel would have to be designed much more like a tanker and less like a conventional supply boat. But building such a ship would be cost pro- hibitive, so converting an existing tanker seemed the best bet.

Not just any tanker would do. It had to

Sulfur Tankers to be Converted to Supply Vessels

The sulfur tanker Benno C. Schmidt at her dock in Port Sulfur, La.

JUNEMN2005 2(9-16).qxd 5/26/2005 9:04 AM Page 13

12

12

14

14