Page 14: of Marine News Magazine (July 2005)

Read this page in Pdf, Flash or Html5 edition of July 2005 Marine News Magazine

By Larry Pearson

With few exceptions, marine power is diesel power and emissions levels from diesel engines are coming under increased scrutiny and regulations from the Envi- ronmental Protection Agency.

The levels of acceptable NOx, carbon monoxide and particulate matter for diesel engines in U.S. flagged vessels depends on the displacement of the engine. The

EPA has settled on a liters-per-cylinder measurement to determine the schedule to meet the emission requirements.

For example, marine diesel engines between 1.2 and 2.5 liters per cylinder have had to meet what is known as Tier

Two requirements since 2004. These are engines typically used to power small gensets, bow thrusters, fire pumps and other auxiliary engine requirements.

However, not all of the engines between 1.2 and 2.5 liters per cylinder have to meet Tier Two requirements. "Engines used for emergency generators and other standby power are exemption from these regulations," said Gary Aucoin, marine sales manager for Louisiana Machinery

Inc., Belle Chasse, La., a Caterpillar dis- tributor and major supplier of diesel engines for shipyards in Louisiana.

Larger engines, between 2.5 and 5.0 liters per cylinder must today meet less stringent emissions standards known as

Tier One. These engines are used for main power requirements of marine vessels. "However in 2007, these engines must also meet the tougher standards of Tier two emissions," said Eddie Brown, emis- sions specialist with Cummins Marine, a division of Cummins, Inc., Columbus,

Ind.

To meet these requirements the two largest suppliers of marine diesel engines,

Cummins and Caterpillar, have spent mil- lions on reducing NOx, CO and particu- late matter to comply with EPA regula- tions. "Cummins' approach has been to take their existing engine platforms and make in-cylinder improvements such as adjust- ment to static timing, higher injection pressures, more effective after cooling and optimization of the turbo air," added

Brown. "We have gotten the lower Tier Two numbers we needed on our 6BT and 6C engines lines with these in-cylinder improvements and we are working to do the same with our big engines, the KT

Series and the QSK-60 so they will meet

Tier Two standards in 2007.”

Cummins has also had to drop certain engines from its lineup that would not meet Tier Two requirements last year including the N-14 engine, often used as an auxiliary engine on commercial ves- sels.

In the real word of practical applica- tions, Cummins supplies both Tier One and Tier Two engines on many of the ves- sels it sells. On a typical crew/supply boat, Cummins might supply four Tier

One KT-50 engines for propulsion power and 2-4 of the 6BT or 6C series Tier Two engines for auxiliary power such as gensets, thrusters, pumps and other com- ponents needing diesel power.

Caterpillar has also invested heavily in reducing emissions from its line of diesel engines. Like Cummins, in-cylinder improvements have met Tier One and Tier

Two requirements for maritime engines.

Caterpillar has called these improve- ments ACERT technology. ACERT tech- nology, which reduces emissions at the point of combustion, is comprised of proven Caterpillar technologies in engine electronics, fuel injection systems, com- bustion and aftertreatment.

Caterpillar used this technology to develop a new line of engines for marine use to replace the 3000, 3100, 3200, 3300 and part of the 3400 line of diesel engines.

Now called the C Series engines, they meet Tier Two requirements of the EPA.

Also the ACERT technology will be a foundation upon which to meet future emissions regulations such as require- ments for Tier Two emission standards in their engines larger than 2.5 liters per cylinder.

For example, Master Boat Builders in

Bayou LaBatre, La., is using several of the C-series engines in the new supply boats under construction for several cus- tomers. "To offer our customer's the best values, our vessels are standardized to some extent," said Andre Dubroc, presi- dent of Master Boat Builders.

For example, his 145-ft. and 164-ft. supply boats use a pair of Caterpillar 3508 diesel engines for propulsion. "These engines offer a larger displacement than 2.5 liters per cylinder so they meet current

EPA regs as Tier One engines," Dubroc said. "However we have gone to Caterpillar

C-9 engines for our gensets that offer 150 kW of power. The old 3306 and 3406 engines are not used anymore since they do not meet the new emissions standards,"

Dubroc added.

Caterpillar C-12 engines, rated at 340 hp are used for higher horsepower appli- cations such as bow thrusters. Like the C- 9, these engines are Tier Two compliant as well.

On their larger 185-ft. supply vessels,

Master Boat uses Tier One Caterpillar 3512 engines for main propulsion and a pair of Caterpillar C-18 engines each sup- plying 550kW of electrical power and a smaller C-9 engine adds another 250 kW of electric power.

Master Boat Builders is currently build- ing supply boats for Abdon Callais Off- shore, Golden Meadow, La. and Seacor

Marine, Houston, Texas.

The future of EPA regulations for marine engines is sort of a moving target.

Moving Tier Two emission standards to the larger marine diesels in on track for 2007. Beyond that lies Tier Three and Tier

Four regulations. "No doubt we will have to move outside of the world of in-cylinder changes to meet stricter regulations," Brown believes. "We may be talking about better fuels that may not be available until 2011," Brown said. 14 • MarineNews • July, 2005

ENVIRONMENT

Engine Emissions

Playing the Tier Game

The 167-foot Mr. J.O. is an example of the application of Cummins engines. A quartet of KT-50's, with

Tier One emissions, propels this crew/supply boat while a pair of 6BT engines, rated at Tier Two drive generators. The Mr. J.O. was built by Neauville Boat Works, Loreauville, La.

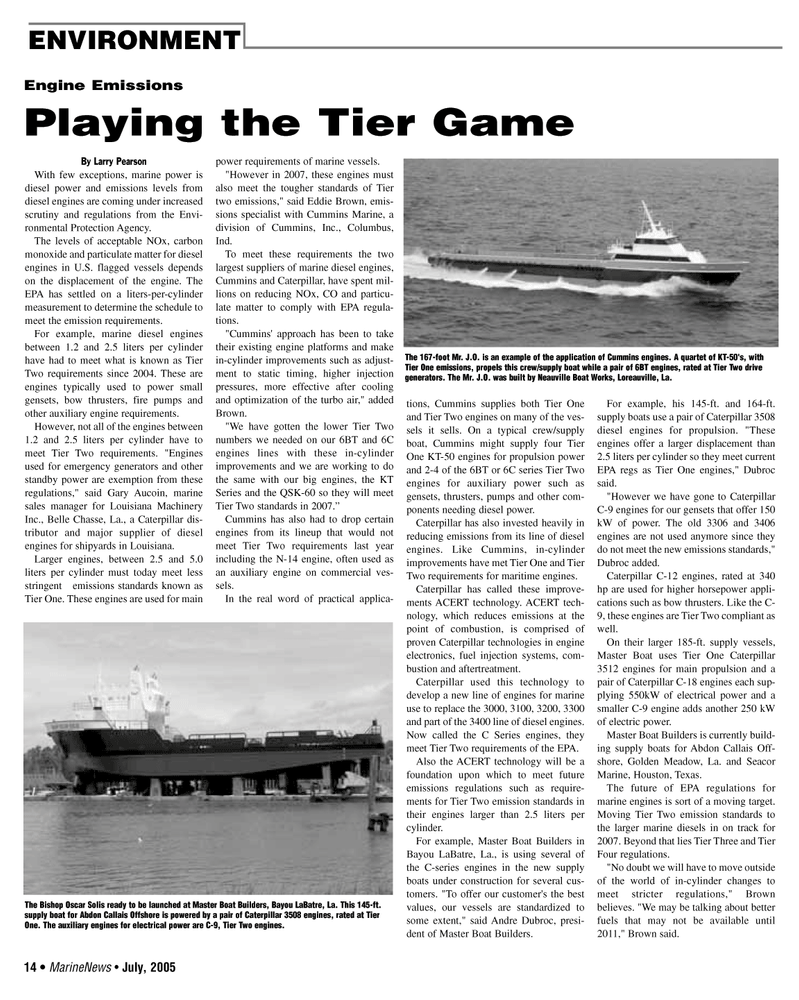

The Bishop Oscar Solis ready to be launched at Master Boat Builders, Bayou LaBatre, La. This 145-ft. supply boat for Abdon Callais Offshore is powered by a pair of Caterpillar 3508 engines, rated at Tier

One. The auxiliary engines for electrical power are C-9, Tier Two engines.

JUlyMN2005 2(9-16).qxd 6/30/2005 1:49 PM Page 14

13

13

15

15