Page 51: of Marine News Magazine (June 2011)

CEO Six-Pack: The Leadership Edition

Read this page in Pdf, Flash or Html5 edition of June 2011 Marine News Magazine

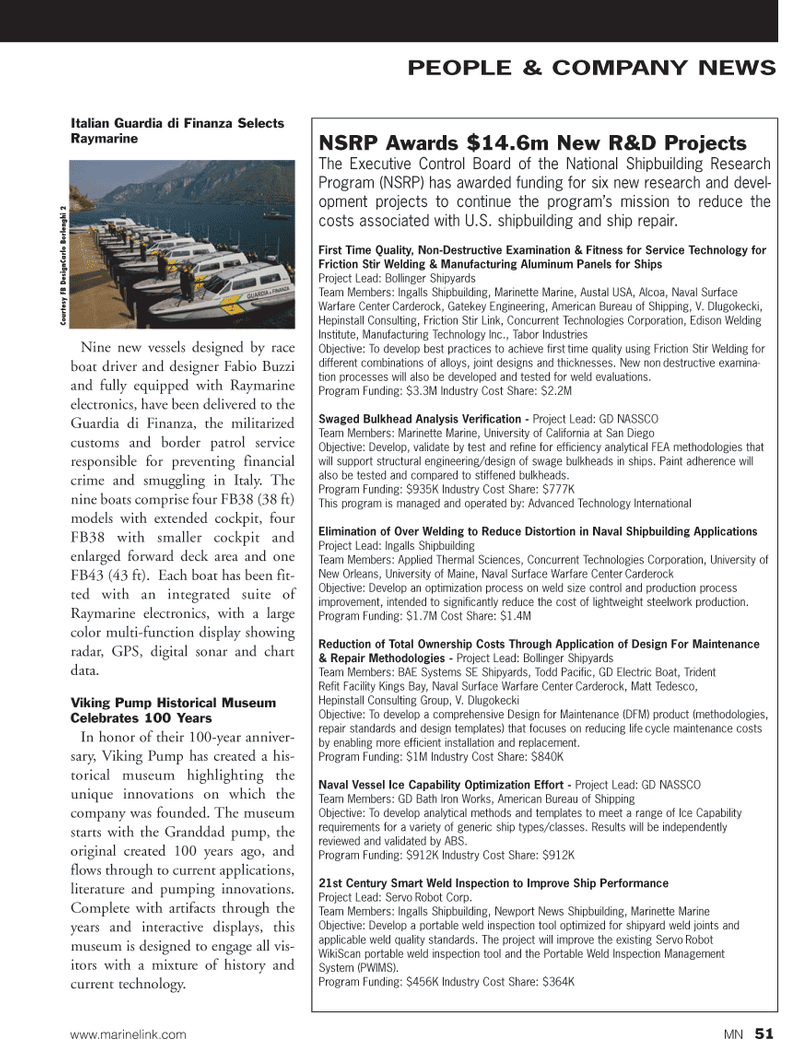

Italian Guardia di Finanza Selects

Raymarine

Nine new vessels designed by race boat driver and designer Fabio Buzzi and fully equipped with Raymarine electronics, have been delivered to the

Guardia di Finanza, the militarized customs and border patrol service responsible for preventing financial crime and smuggling in Italy. The nine boats comprise four FB38 (38 ft) models with extended cockpit, four

FB38 with smaller cockpit and enlarged forward deck area and one

FB43 (43 ft). Each boat has been fit- ted with an integrated suite of

Raymarine electronics, with a large color multi-function display showing radar, GPS, digital sonar and chart data.

Viking Pump Historical Museum

Celebrates 100 Years

In honor of their 100-year anniver- sary, Viking Pump has created a his- torical museum highlighting the unique innovations on which the company was founded. The museum starts with the Granddad pump, the original created 100 years ago, and flows through to current applications, literature and pumping innovations.

Complete with artifacts through the years and interactive displays, this museum is designed to engage all vis- itors with a mixture of history and current technology. www.marinelink.com MN 51

PEOPLE & COMPANY NEWS

Courtesy FB DesignCarlo Borlenghi 2

NSRP Awards $14.6m New R&D Projects

The Executive Control Board of the National Shipbuilding Research

Program (NSRP) has awarded funding for six new research and devel- opment projects to continue the program’s mission to reduce the costs associated with U.S. shipbuilding and ship repair.

First Time Quality, Non-Destructive Examination & Fitness for Service Technology for

Friction Stir Welding & Manufacturing Aluminum Panels for Ships

Project Lead: Bollinger Shipyards

Team Members: Ingalls Shipbuilding, Marinette Marine, Austal USA, Alcoa, Naval Surface

Warfare Center Carderock, Gatekey Engineering, American Bureau of Shipping, V. Dlugokecki,

Hepinstall Consulting, Friction Stir Link, Concurrent Technologies Corporation, Edison Welding

Institute, Manufacturing Technology Inc., Tabor Industries

Objective: To develop best practices to achieve first time quality using Friction Stir Welding for different combinations of alloys, joint designs and thicknesses. New non destructive examina- tion processes will also be developed and tested for weld evaluations.

Program Funding: $3.3M Industry Cost Share: $2.2M

Swaged Bulkhead Analysis Verification - Project Lead: GD NASSCO

Team Members: Marinette Marine, University of California at San Diego

Objective: Develop, validate by test and refine for efficiency analytical FEA methodologies that will support structural engineering/design of swage bulkheads in ships. Paint adherence will also be tested and compared to stiffened bulkheads.

Program Funding: $935K Industry Cost Share: $777K

This program is managed and operated by: Advanced Technology International

Elimination of Over Welding to Reduce Distortion in Naval Shipbuilding Applications

Project Lead: Ingalls Shipbuilding

Team Members: Applied Thermal Sciences, Concurrent Technologies Corporation, University of

New Orleans, University of Maine, Naval Surface Warfare Center Carderock

Objective: Develop an optimization process on weld size control and production process improvement, intended to significantly reduce the cost of lightweight steelwork production.

Program Funding: $1.7M Cost Share: $1.4M

Reduction of Total Ownership Costs Through Application of Design For Maintenance & Repair Methodologies - Project Lead: Bollinger Shipyards

Team Members: BAE Systems SE Shipyards, Todd Pacific, GD Electric Boat, Trident

Refit Facility Kings Bay, Naval Surface Warfare Center Carderock, Matt Tedesco,

Hepinstall Consulting Group, V. Dlugokecki

Objective: To develop a comprehensive Design for Maintenance (DFM) product (methodologies, repair standards and design templates) that focuses on reducing life cycle maintenance costs by enabling more efficient installation and replacement.

Program Funding: $1M Industry Cost Share: $840K

Naval Vessel Ice Capability Optimization Effort - Project Lead: GD NASSCO

Team Members: GD Bath Iron Works, American Bureau of Shipping

Objective: To develop analytical methods and templates to meet a range of Ice Capability requirements for a variety of generic ship types/classes. Results will be independently reviewed and validated by ABS.

Program Funding: $912K Industry Cost Share: $912K 21st Century Smart Weld Inspection to Improve Ship Performance

Project Lead: Servo Robot Corp.

Team Members: Ingalls Shipbuilding, Newport News Shipbuilding, Marinette Marine

Objective: Develop a portable weld inspection tool optimized for shipyard weld joints and applicable weld quality standards. The project will improve the existing Servo Robot

WikiScan portable weld inspection tool and the Portable Weld Inspection Management

System (PWIMS).

Program Funding: $456K Industry Cost Share: $364K

50

50

52

52