Page 44: of Marine News Magazine (July 2011)

Workboat Power

Read this page in Pdf, Flash or Html5 edition of July 2011 Marine News Magazine

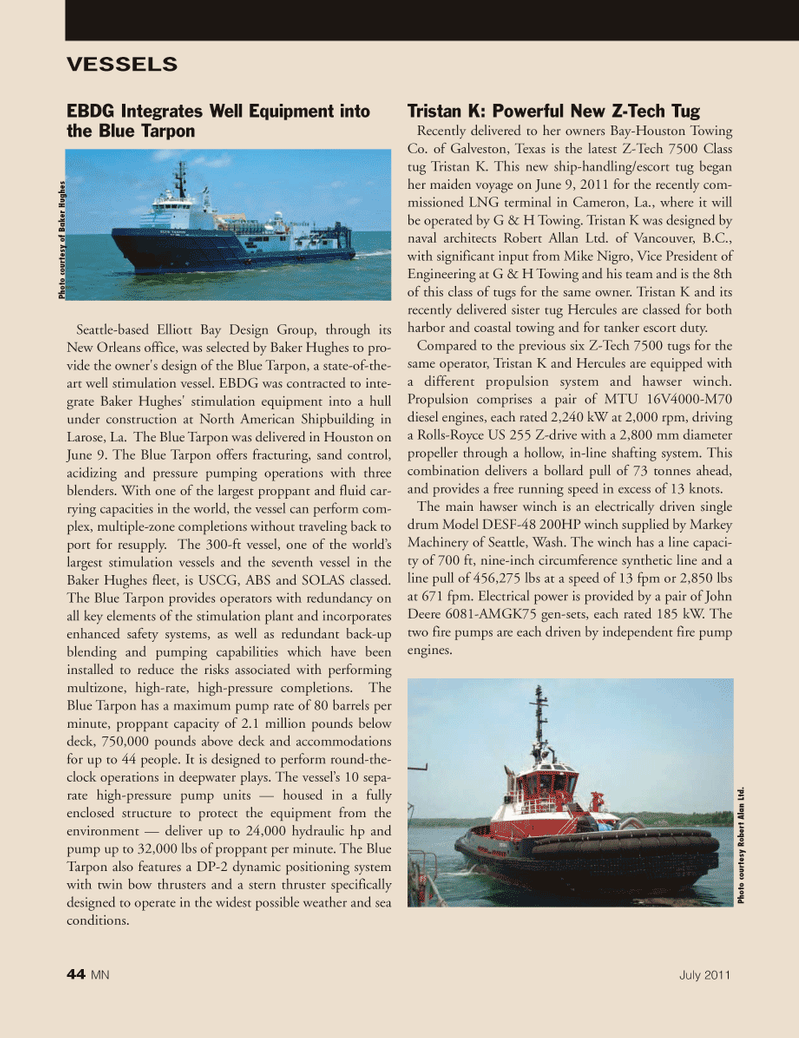

44MNJuly 2011EBDG Integrates Well Equipment into the Blue Tarpon Seattle-based Elliott Bay Design Group, through its New Orleans office, was selected by Baker Hughes to pro- vide the owner's design of the Blue Tarpon, a state-of-the- art well stimulation vessel. EBDG was contracted to inte- grate Baker Hughes' stimulation equipment into a hull under construction at North American Shipbuilding in Larose, La. The Blue Tarpon was delivered in Houston on June 9. The Blue Tarpon offers fracturing, sand control, acidizing and pressure pumping operations with three blenders. With one of the largest proppant and fluid car- rying capacities in the world, the vessel can perform com- plex, multiple-zone completions without traveling back to port for resupply. The 300-ft vessel, one of the worlds largest stimulation vessels and the seventh vessel in the Baker Hughes fleet, is USCG, ABS and SOLAS classed. The Blue Tarpon provides operators with redundancy on all key elements of the stimulation plant and incorporatesenhanced safety systems, as well as redundant back-up blending and pumping capabilities which have been installed to reduce the risks associated with performing multizone, high-rate, high-pressure completions. The Blue Tarpon has a maximum pump rate of 80 barrels per minute, proppant capacity of 2.1 million pounds below deck, 750,000 pounds above deck and accommodations for up to 44 people. It is designed to perform round-the- clock operations in deepwater plays. The vessels 10 sepa- rate high-pressure pump units ? housed in a fully enclosed structure to protect the equipment from the environment ? deliver up to 24,000 hydraulic hp and pump up to 32,000 lbs of proppant per minute. The Blue Tarpon also features a DP-2 dynamic positioning system with twin bow thrusters and a stern thruster specifically designed to operate in the widest possible weather and sea conditions.Tristan K: Powerful New Z-Tech Tug Recently delivered to her owners Bay-Houston Towing Co. of Galveston, Texas is the latest Z-Tech 7500 Class tug Tristan K. This new ship-handling/escort tug began her maiden voyage on June 9, 2011 for the recently com- missioned LNG terminal in Cameron, La., where it will be operated by G & H Towing. Tristan K was designed by naval architects Robert Allan Ltd. of Vancouver, B.C., with significant input from Mike Nigro, Vice President of Engineering at G & H Towing and his team and is the 8th of this class of tugs for the same owner. Tristan K and its recently delivered sister tug Hercules are classed for both harbor and coastal towing and for tanker escort duty. Compared to the previous six Z-Tech 7500 tugs for the same operator, Tristan K and Hercules are equipped with a different propulsion system and hawser winch. Propulsion comprises a pair of MTU 16V4000-M70 diesel engines, each rated 2,240 kW at 2,000 rpm, drivinga Rolls- Royce US 255 Z-drive with a 2,800 mm diameter propeller through a hollow, in-line shafting system. This combination delivers a bollard pull of 73 tonnes ahead, and provides a free running speed in excess of 13 knots. The main hawser winch is an electrically driven single drum Model DESF-48 200HP winch supplied by Markey Machinery of Seattle, Wash. The winch has a line capaci- ty of 700 ft, nine-inch circumference synthetic line and a line pull of 456,275 lbs at a speed of 13 fpm or 2,850 lbsat 671 fpm. Electrical power is provided by a pair of John Deere 6081-AMGK75 gen-sets, each rated 185 kW. The two fire pumps are each driven by independent fire pump engines.VESSELSPhoto courtesy of Baker HughesPhoto courtesy Robert Alan Ltd.

43

43

45

45