Page 36: of Marine News Magazine (January 2012)

Vessel Construction & Repair

Read this page in Pdf, Flash or Html5 edition of January 2012 Marine News Magazine

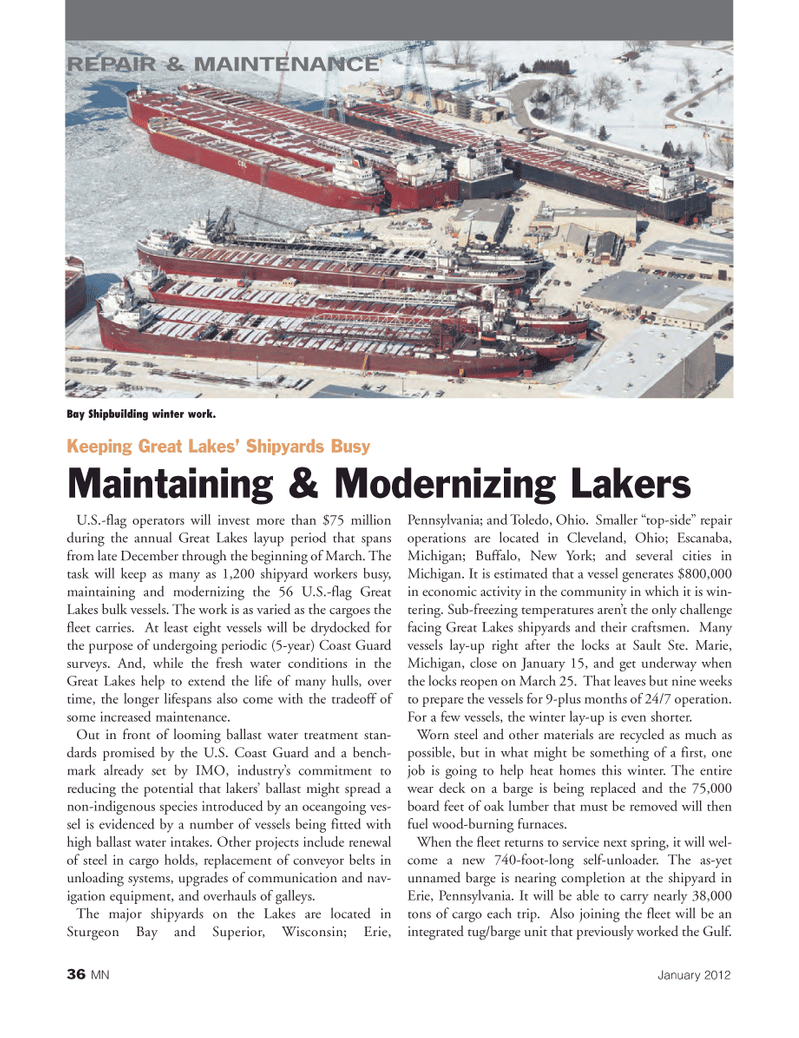

36MNJanuary 2012 REPAIR & MAINTENANCE Keeping Great Lakes? Shipyards Busy Maintaining & Modernizing Lakers U.S.-flag operators will invest more than $75 million during the annual Great Lakes layup period that spans from late December through the beginning of March. The task will keep as many as 1,200 shipyard workers busy, maintaining and modernizing the 56 U.S.-flag Great Lakes bulk vessels. The work is as varied as the cargoes the fleet carries. At least eight vessels will be drydocked for the purpose of undergoing periodic (5-year) Coast Guard surveys. And, while the fresh water conditions in the Great Lakes help to extend the life of many hulls, over time, the longer lifespans also come with the tradeoff ofsome increased maintenance. Out in front of looming ballast water treatment stan- dards promised by the U.S. Coast Guard and a bench- mark already set by IMO, industry?s commitment to reducing the potential that lakers? ballast might spread a non-indigenous species introduced by an oceangoing ves- sel is evidenced by a number of vessels being fitted with high ballast water intakes. Other projects include renewal of steel in cargo holds, replacement of conveyor belts in unloading systems, upgrades of communication and nav-igation equipment, and overhauls of galleys. The major shipyards on the Lakes are located in Sturgeon Bay and Superior, Wisconsin; Erie, Pennsylvania; and Toledo, Ohio. Smaller ?top-side? repair operations are located in Cleveland, Ohio; Escanaba, Michigan; Buffalo, New York; and several cities in Michigan. It is estimated that a vessel generates $800,000 in economic activity in the community in which it is win-tering. Sub-freezing temperatures aren?t the only challenge facing Great Lakes shipyards and their craftsmen. Many vessels lay-up right after the locks at Sault Ste. Marie, Michigan, close on January 15, and get underway when the locks reopen on March 25. That leaves but nine weeks to prepare the vessels for 9-plus months of 24/7 operation. For a few vessels, the winter lay-up is even shorter. Worn steel and other materials are recycled as much as possible, but in what might be something of a first, onejob is going to help heat homes this winter. The entire wear deck on a barge is being replaced and the 75,000 board feet of oak lumber that must be removed will then fuel wood-burning furnaces.When the fleet returns to service next spring, it will wel- come a new 740-foot-long self-unloader. The as-yet unnamed barge is nearing completion at the shipyard in Erie, Pennsylvania. It will be able to carry nearly 38,000 tons of cargo each trip. Also joining the fleet will be an integrated tug/barge unit that previously worked the Gulf. Bay Shipbuilding winter work.MN#1 (32-42):MN 2011 Layouts 1/5/2012 1:37 PM Page 36

35

35

37

37