Page 42: of Marine News Magazine (June 2012)

Dredging & Marine Construction

Read this page in Pdf, Flash or Html5 edition of June 2012 Marine News Magazine

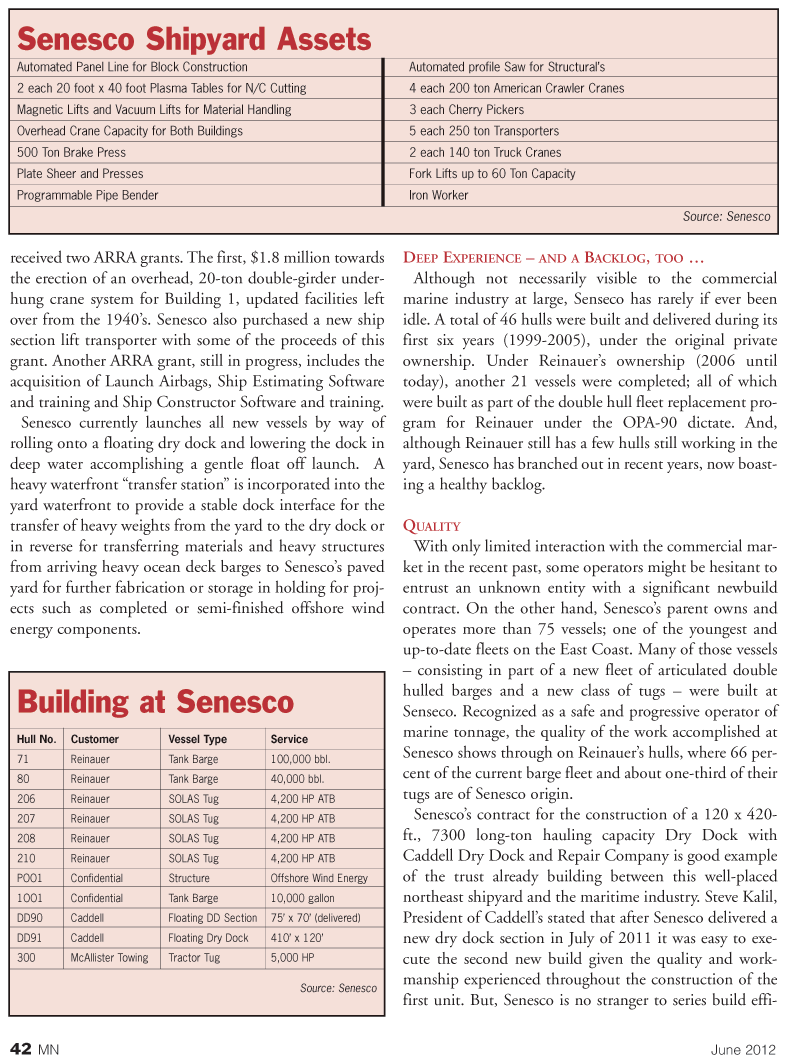

received two ARRA grants. The first, $1.8 million towards the erection of an overhead, 20-ton double-girder under- hung crane system for Building 1, updated facilities left over from the 1940s. Senesco also purchased a new ship section lift transporter with some of the proceeds of this grant. Another ARRA grant, still in progress, includes the acquisition of Launch Airbags, Ship Estimating Software and training and Ship Constructor Software and training. Senesco currently launches all new vessels by way of rolling onto a floating dry dock and lowering the dock in deep water accomplishing a gentle float off launch. A heavy waterfront transfer station? is incorporated into the yard waterfront to provide a stable dock interface for the transfer of heavy weights from the yard to the dry dock or in reverse for transferring materials and heavy structures from arriving heavy ocean deck barges to Senescos paved yard for further fabrication or storage in holding for proj- ects such as completed or semi-finished offshore wind energy components.DEEPEXPERIENCE ? ANDA BACKLOG , TOO ?Although not necessarily visible to the commercial marine industry at large, Senseco has rarely if ever been idle. A total of 46 hulls were built and delivered during its first six years (1999-2005), under the original private ownership. Under Reinauers ownership (2006 until today), another 21 vessels were completed; all of which were built as part of the double hull fleet replacement pro- gram for Reinauer under the OPA-90 dictate. And, although Reinauer still has a few hulls still working in the yard, Senesco has branched out in recent years, now boast- ing a healthy backlog.QUALITY With only limited interaction with the commercial mar- ket in the recent past, some operators might be hesitant to entrust an unknown entity with a significant newbuild contract. On the other hand, Senescos parent owns and operates more than 75 vessels; one of the youngest and up-to-date fleets on the East Coast. Many of those vessels ? consisting in part of a new fleet of articulated double hulled barges and a new class of tugs ? were built at Senseco. Recognized as a safe and progressive operator of marine tonnage, the quality of the work accomplished at Senesco shows through on Reinauers hulls, where 66 per- cent of the current barge fleet and about one-third of their tugs are of Senesco origin. Senescos contract for the construction of a 120 x 420- ft., 7300 long-ton hauling capacity Dry Dock with Caddell Dry Dock and Repair Company is good example of the trust already building between this well-placed northeast shipyard and the maritime industry. Steve Kalil, President of Caddells stated that after Senesco delivered a new dry dock section in July of 2011 it was easy to exe- cute the second new build given the quality and work- manship experienced throughout the construction of the first unit. But, Senesco is no stranger to series build effi- 42MNJune 2012Senesco Shipyard Assets Automated Panel Line for Block ConstructionAutomated profile Saw for Structurals 2 each 20 foot x 40 foot Plasma Tables for N/C Cutting4 each 200 ton American Crawler Cranes Magnetic Lifts and Vacuum Lifts for Material Handling3 each Cherry Pickers Overhead Crane Capacity for Both Buildings5 each 250 ton Transporters 500 Ton Brake Press2 each 140 ton Truck Cranes Plate Sheer and PressesFork Lifts up to 60 Ton Capacity Programmable Pipe BenderIron Worker Source: Senesco Building at SenescoHull No.CustomerVessel TypeService 71ReinauerTank Barge100,000 bbl. 80ReinauerTank Barge40,000 bbl. 206ReinauerSOLAS Tug4,200 HP ATB 207ReinauerSOLAS Tug4,200 HP ATB 208ReinauerSOLAS Tug4,200 HP ATB 210ReinauerSOLAS Tug4,200 HP ATB POO1ConfidentialStructureOffshore Wind Energy 1OO1ConfidentialTank Barge10,000 gallon DD90CaddellFloating DD Section75 x 70 (delivered) DD91CaddellFloating Dry Dock410 x 120 300McAllister TowingTractor Tug5,000 HP Source: Senesco

41

41

43

43