Page 61: of Marine News Magazine (November 2012)

Workboat Annual

Read this page in Pdf, Flash or Html5 edition of November 2012 Marine News Magazine

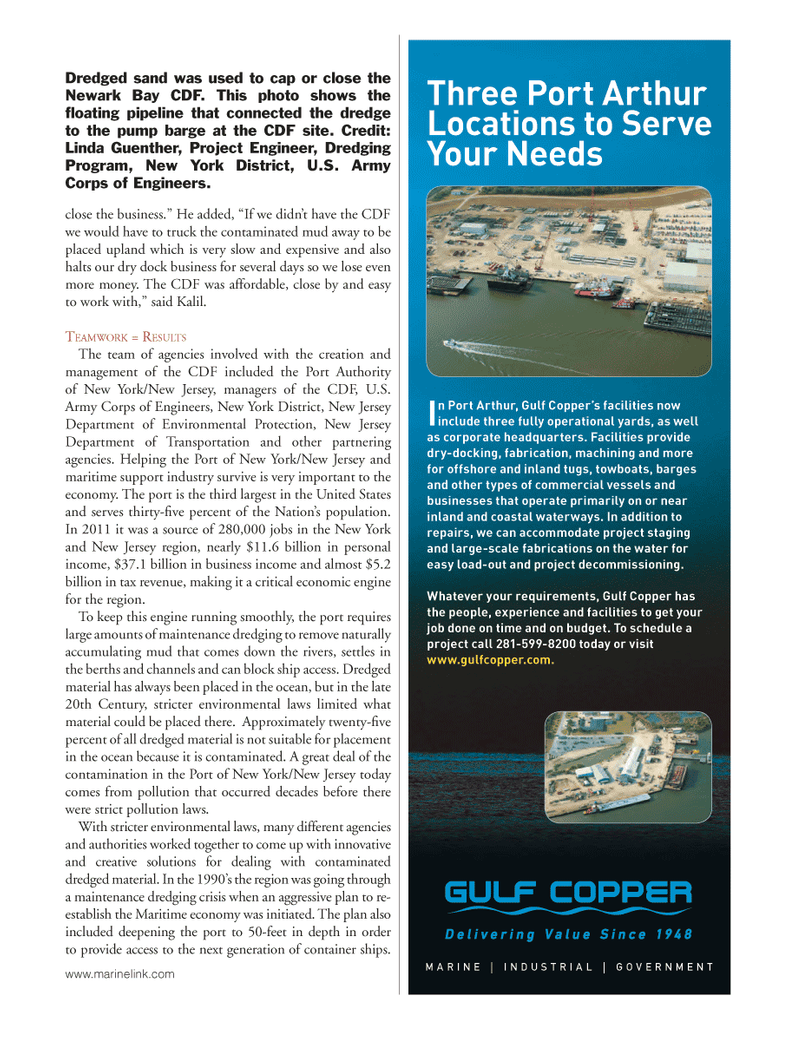

close the business.? He added, ?If we didn?t have the CDF we would have to truck the contaminated mud away to be placed upland which is very slow and expensive and also halts our dry dock business for several days so we lose even more money. The CDF was affordable, close by and easy to work with,? said Kalil. TEAMWORK = RESULTS The team of agencies involved with the creation and management of the CDF included the Port Authority of New York/New Jersey, managers of the CDF, U.S. Army Corps of Engineers, New York District, New Jersey Department of Environmental Protection, New Jersey Department of Transportation and other partnering agencies. Helping the Port of New York/New Jersey and maritime support industry survive is very important to the economy. The port is the third largest in the United States and serves thirty- ve percent of the Nation?s population. In 2011 it was a source of 280,000 jobs in the New York and New Jersey region, nearly $11.6 billion in personal income, $37.1 billion in business income and almost $5.2 billion in tax revenue, making it a critical economic engine for the region. To keep this engine running smoothly, the port requires large amounts of maintenance dredging to remove naturally accumulating mud that comes down the rivers, settles in the berths and channels and can block ship access. Dredged material has always been placed in the ocean, but in the late 20th Century, stricter environmental laws limited what material could be placed there. Approximately twenty- ve percent of all dredged material is not suitable for placement in the ocean because it is contaminated. A great deal of the contamination in the Port of New York/New Jersey today comes from pollution that occurred decades before there were strict pollution laws. With stricter environmental laws, many different agencies and authorities worked together to come up with innovative and creative solutions for dealing with contaminated dredged material. In the 1990?s the region was going through a maintenance dredging crisis when an aggressive plan to re- establish the Maritime economy was initiated. The plan also included deepening the port to 50-feet in depth in order to provide access to the next generation of container ships. Three Port Arthur Locations to Serve Your Needs In Port Arthur, Gulf Coppers facilities now include three fully operational yards, as well as corporate headquarters. Facilities provide dry-docking, fabrication, machining and more for offshore and inland tugs, towboats, barges and other types of commercial vessels and businesses that operate primarily on or near inland and coastal waterways. In addition to repairs, we can accommodate project staging and large-scale fabrications on the water for easy load-out and project decommissioning. Whatever your requirements, Gulf Copper has the people, experience and facilities to get your job done on time and on budget. To schedule a project call 281-599-8200 today or visit www.gulfcopper.com. MARINE | INDUSTRIAL | GOVERNMENT Dredged sand was used to cap or close the Newark Bay CDF. This photo shows the ß oating pipeline that connected the dredge to the pump barge at the CDF site. Credit: Linda Guenther, Project Engineer, Dredging Program, New York District, U.S. Army Corps of Engineers.www.marinelink.com MNNov2012 Layout 50-65.indd 61MNNov2012 Layout 50-65.indd 6111/6/2012 4:23:43 PM11/6/2012 4:23:43 PM

60

60

62

62