Page 33: of Marine News Magazine (December 2012)

Innovative Products &

Read this page in Pdf, Flash or Html5 edition of December 2012 Marine News Magazine

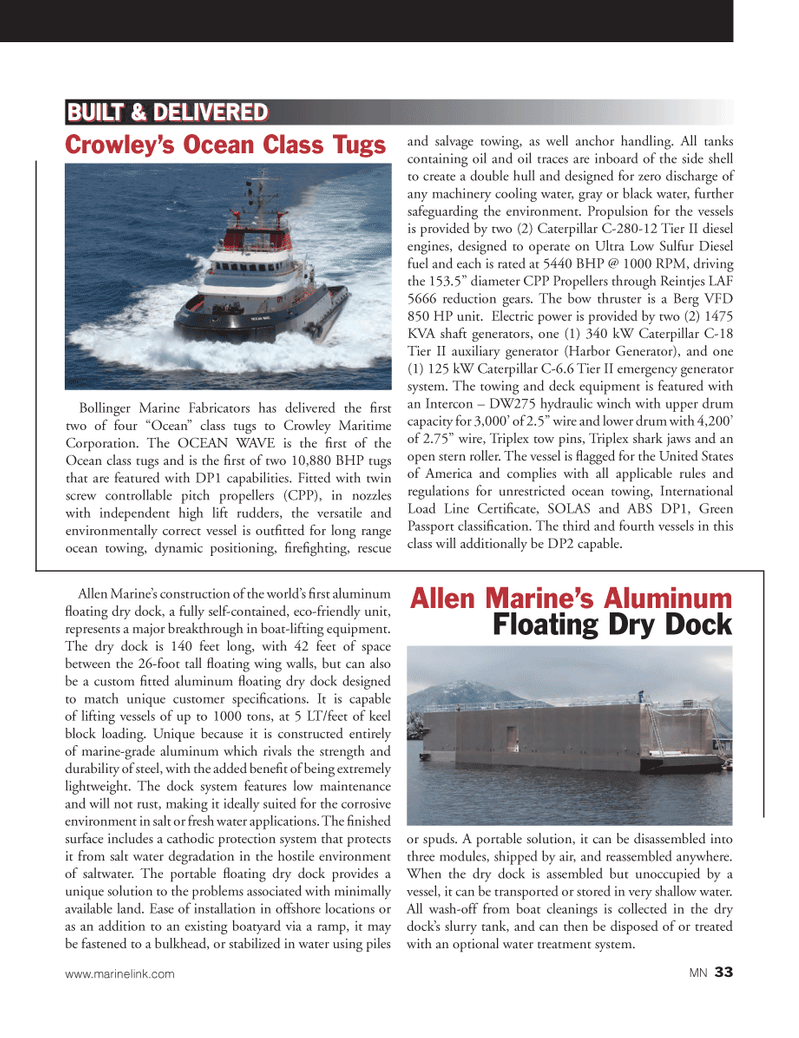

BUILT & DELIVERED BUILT & DELIVERED Bollinger Marine Fabricators has delivered the Þ rst two of four ÒOceanÓ class tugs to Crowley Maritime Corporation. The OCEAN WAVE is the Þ rst of the Ocean class tugs and is the Þ rst of two 10,880 BHP tugs that are featured with DP1 capabilities. Fitted with twin screw controllable pitch propellers (CPP), in nozzles with independent high lift rudders, the versatile and environmentally correct vessel is outÞ tted for long range ocean towing, dynamic positioning, Þ reÞ ghting, rescue and salvage towing, as well anchor handling. All tanks containing oil and oil traces are inboard of the side shell to create a double hull and designed for zero discharge of any machinery cooling water, gray or black water, further safeguarding the environment. Propulsion for the vessels is provided by two (2) Caterpillar C-280-12 Tier II diesel engines, designed to operate on Ultra Low Sulfur Diesel fuel and each is rated at 5440 BHP @ 1000 RPM, driving the 153.5Ó diameter CPP Propellers through Reintjes LAF 5666 reduction gears. The bow thruster is a Berg VFD 850 HP unit. Electric power is provided by two (2) 1475 KVA shaft generators, one (1) 340 kW Caterpillar C-18 Tier II auxiliary generator (Harbor Generator), and one (1) 125 kW Caterpillar C-6.6 Tier II emergency generator system. The towing and deck equipment is featured with an Intercon Ð DW275 hydraulic winch with upper drum capacity for 3,000Õ of 2.5Ó wire and lower drum with 4,200Õ of 2.75Ó wire, Triplex tow pins, Triplex shark jaws and an open stern roller. The vessel is ß agged for the United States of America and complies with all applicable rules and regulations for unrestricted ocean towing, International Load Line CertiÞ cate, SOLAS and ABS DP1, Green Passport classiÞ cation. The third and fourth vessels in this class will additionally be DP2 capable. Crowley?s Ocean Class Tugs Allen MarineÕs construction of the worldÕs Þ rst aluminum ß oating dry dock, a fully self-contained, eco-friendly unit, represents a major breakthrough in boat-lifting equipment. The dry dock is 140 feet long, with 42 feet of space between the 26-foot tall ß oating wing walls, but can also be a custom Þ tted aluminum ß oating dry dock designed to match unique customer speciÞ cations. It is capable of lifting vessels of up to 1000 tons, at 5 LT/feet of keel block loading. Unique because it is constructed entirely of marine-grade aluminum which rivals the strength and durability of steel, with the added beneÞ t of being extremely lightweight. The dock system features low maintenance and will not rust, making it ideally suited for the corrosive environment in salt or fresh water applications. The Þ nished surface includes a cathodic protection system that protects it from salt water degradation in the hostile environment of saltwater. The portable ß oating dry dock provides a unique solution to the problems associated with minimally available land. Ease of installation in offshore locations or as an addition to an existing boatyard via a ramp, it may be fastened to a bulkhead, or stabilized in water using piles or spuds. A portable solution, it can be disassembled into three modules, shipped by air, and reassembled anywhere. When the dry dock is assembled but unoccupied by a vessel, it can be transported or stored in very shallow water. All wash-off from boat cleanings is collected in the dry dockÕs slurry tank, and can then be disposed of or treated with an optional water treatment system. Allen Marine?s Aluminum Floating Dry Dockwww.marinelink.com MN 33

32

32

34

34