Page 26: of Marine News Magazine (July 2013)

Propulsion Technology

Read this page in Pdf, Flash or Html5 edition of July 2013 Marine News Magazine

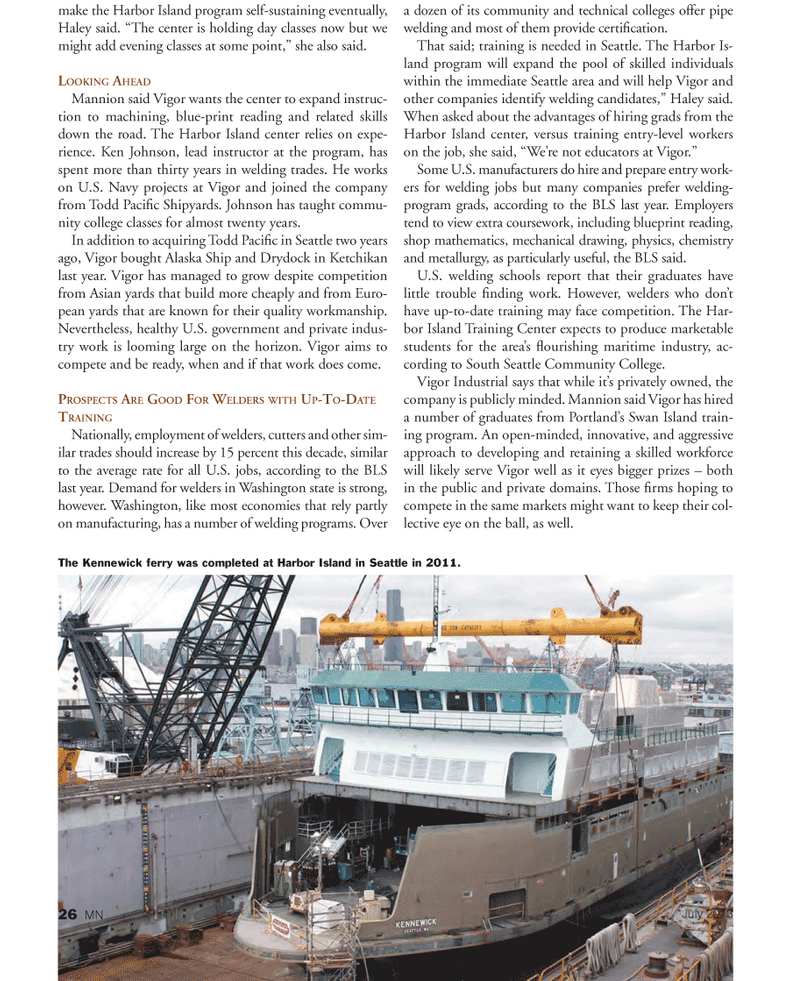

make the Harbor Island program self-sustaining eventually, Haley said. The center is holding day classes now but we might add evening classes at some point,? she also said. LOOKING AHEADMannion said Vigor wants the center to expand instruc- tion to machining, blue-print reading and related skills down the road. The Harbor Island center relies on expe- rience. Ken Johnson, lead instructor at the program, has spent more than thirty years in welding trades. He works on U.S. Navy projects at Vigor and joined the company from Todd Paci? c Shipyards. Johnson has taught commu- nity college classes for almost twenty years. In addition to acquiring Todd Paci? c in Seattle two years ago, Vigor bought Alaska Ship and Drydock in Ketchikan last year. Vigor has managed to grow despite competition from Asian yards that build more cheaply and from Euro- pean yards that are known for their quality workmanship. Nevertheless, healthy U.S. government and private indus- try work is looming large on the horizon. Vigor aims to compete and be ready, when and if that work does come. PROSPECTS ARE GOOD FOR WELDERS WITH UP-TO-DATE TRAININGNationally, employment of welders, cutters and other sim- ilar trades should increase by 15 percent this decade, similar to the average rate for all U.S. jobs, according to the BLS last year. Demand for welders in Washington state is strong, however. Washington, like most economies that rely partly on manufacturing, has a number of welding programs. Over a dozen of its community and technical colleges offer pipe welding and most of them provide certi? cation.That said; training is needed in Seattle. The Harbor Is- land program will expand the pool of skilled individuals within the immediate Seattle area and will help Vigor and other companies identify welding candidates,? Haley said. When asked about the advantages of hiring grads from the Harbor Island center, versus training entry-level workers on the job, she said, Were not educators at Vigor.? Some U.S. manufacturers do hire and prepare entry work- ers for welding jobs but many companies prefer welding- program grads, according to the BLS last year. Employers tend to view extra coursework, including blueprint reading, shop mathematics, mechanical drawing, physics, chemistry and metallurgy, as particularly useful, the BLS said. U.S. welding schools report that their graduates have little trouble ? nding work. However, welders who dont have up-to-date training may face competition. The Har- bor Island Training Center expects to produce marketable students for the areas ? ourishing maritime industry, ac- cording to South Seattle Community College. Vigor Industrial says that while its privately owned, the company is publicly minded. Mannion said Vigor has hired a number of graduates from Portlands Swan Island train- ing program. An open-minded, innovative, and aggressive approach to developing and retaining a skilled workforce will likely serve Vigor well as it eyes bigger prizes ? both in the public and private domains. Those ? rms hoping to compete in the same markets might want to keep their col- lective eye on the ball, as well. The Kennewick ferry was completed at Harbor Island in Seattle in 2011.26 MNJuly 2013MN July2013 Layout 18-31.indd 266/27/2013 1:02:08 PM

25

25

27

27