Page 62: of Marine News Magazine (September 2013)

Workboat Annual

Read this page in Pdf, Flash or Html5 edition of September 2013 Marine News Magazine

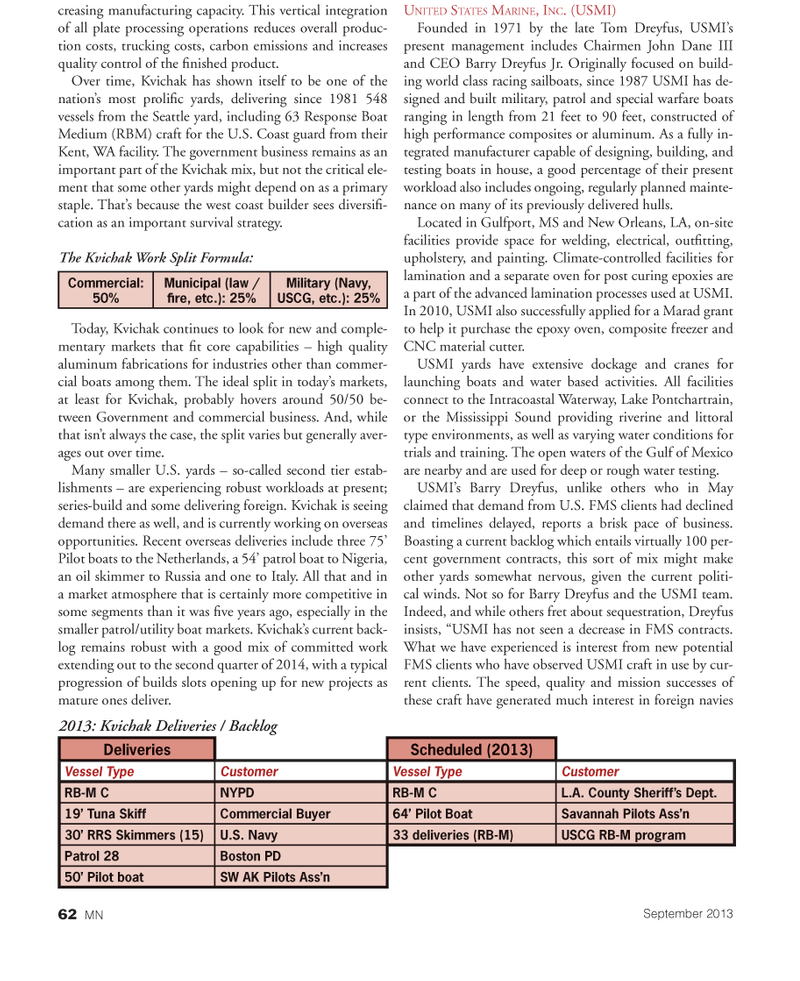

creasing manufacturing capacity. This vertical integration of all plate processing operations reduces overall produc- tion costs, trucking costs, carbon emissions and increases quality control of the ? nished product. Over time, Kvichak has shown itself to be one of the nations most proli? c yards, delivering since 1981 548 vessels from the Seattle yard, including 63 Response Boat Medium (RBM) craft for the U.S. Coast guard from their Kent, WA facility. The government business remains as an important part of the Kvichak mix, but not the critical ele- ment that some other yards might depend on as a primary staple. Thats because the west coast builder sees diversi? -cation as an important survival strategy. The Kvichak Work Split Formula: Today, Kvichak continues to look for new and comple- mentary markets that ? t core capabilities ? high quality aluminum fabrications for industries other than commer-cial boats among them. The ideal split in todays markets, at least for Kvichak, probably hovers around 50/50 be- tween Government and commercial business. And, while that isnt always the case, the split varies but generally aver- ages out over time. Many smaller U.S. yards ? so-called second tier estab- lishments ? are experiencing robust workloads at present; series-build and some delivering foreign. Kvichak is seeing demand there as well, and is currently working on overseas opportunities. Recent overseas deliveries include three 75 Pilot boats to the Netherlands, a 54 patrol boat to Nigeria, an oil skimmer to Russia and one to Italy. All that and in a market atmosphere that is certainly more competitive in some segments than it was ? ve years ago, especially in the smaller patrol/utility boat markets. Kvichaks current back- log remains robust with a good mix of committed work extending out to the second quarter of 2014, with a typical progression of builds slots opening up for new projects as mature ones deliver. UNITED STATES MARINE, INC. (USMI)Founded in 1971 by the late Tom Dreyfus, USMIs present management includes Chairmen John Dane III and CEO Barry Dreyfus Jr. Originally focused on build- ing world class racing sailboats, since 1987 USMI has de-signed and built military, patrol and special warfare boats ranging in length from 21 feet to 90 feet, constructed of high performance composites or aluminum. As a fully in- tegrated manufacturer capable of designing, building, and testing boats in house, a good percentage of their present workload also includes ongoing, regularly planned mainte- nance on many of its previously delivered hulls. Located in Gulfport, MS and New Orleans, LA, on-site facilities provide space for welding, electrical, out? tting, upholstery, and painting. Climate-controlled facilities for lamination and a separate oven for post curing epoxies are a part of the advanced lamination processes used at USMI. In 2010, USMI also successfully applied for a Marad grant to help it purchase the epoxy oven, composite freezer and CNC material cutter. USMI yards have extensive dockage and cranes for launching boats and water based activities. All facilities connect to the Intracoastal Waterway, Lake Pontchartrain, or the Mississippi Sound providing riverine and littoral type environments, as well as varying water conditions for trials and training. The open waters of the Gulf of Mexico are nearby and are used for deep or rough water testing. USMIs Barry Dreyfus, unlike others who in May claimed that demand from U.S. FMS clients had declined and timelines delayed, reports a brisk pace of business. Boasting a current backlog which entails virtually 100 per- cent government contracts, this sort of mix might make other yards somewhat nervous, given the current politi- cal winds. Not so for Barry Dreyfus and the USMI team. Indeed, and while others fret about sequestration, Dreyfus insists, USMI has not seen a decrease in FMS contracts. What we have experienced is interest from new potential FMS clients who have observed USMI craft in use by cur- rent clients. The speed, quality and mission successes of these craft have generated much interest in foreign navies Commercial: 50%Municipal (law / ? re, etc.): 25% Military (Navy, USCG, etc.): 25%DeliveriesScheduled (2013) Vessel TypeCustomerVessel TypeCustomer RB-M CNYPDRB-M CL.A. County Sheriffs Dept. 19 Tuna SkiffCommercial Buyer64 Pilot BoatSavannah Pilots Assn 30 RRS Skimmers (15)U.S. Navy33 deliveries (RB-M)USCG RB-M program Patrol 28Boston PD 50 Pilot boatSW AK Pilots Assn 2013: Kvichak Deliveries / Backlog September 201362 MNMN Sept2013 Layout 50-65.indd 628/29/2013 4:56:39 PM

61

61

63

63