Page 52: of Marine News Magazine (December 2013)

Innovative Products & Boats of 2012

Read this page in Pdf, Flash or Html5 edition of December 2013 Marine News Magazine

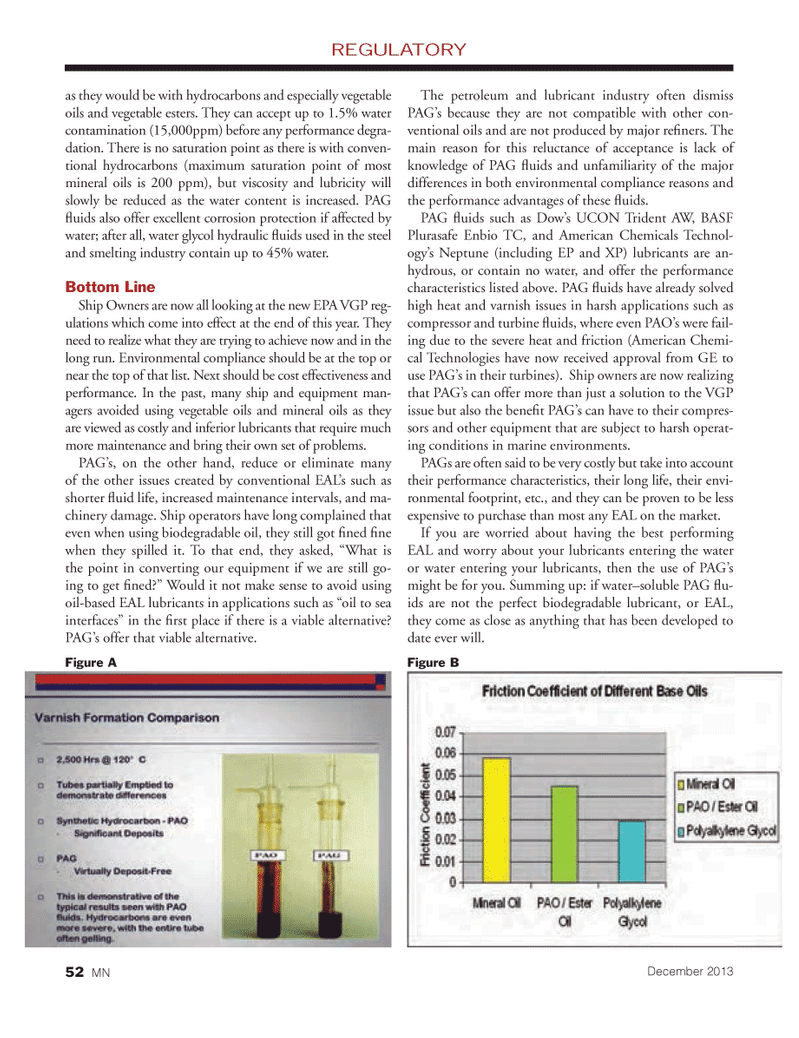

as they would be with hydrocarbons and especially vegetable oils and vegetable esters. They can accept up to 1.5% water contamination (15,000ppm) before any performance degra- dation. There is no saturation point as there is with conven- tional hydrocarbons (maximum saturation point of most mineral oils is 200 ppm), but viscosity and lubricity will slowly be reduced as the water content is increased. PAG ß uids also offer excellent corrosion protection if affected by water; after all, water glycol hydraulic ß uids used in the steel and smelting industry contain up to 45% water. Bottom LineShip Owners are now all looking at the new EPA VGP reg- ulations which come into effect at the end of this year . They need to realize what they are trying to achieve now and in the long run. Environmental compliance should be at the top or near the top of that list. Next should be cost effectiveness and performance. In the past, many ship and equipment man- agers avoided using vegetable oils and mineral oils as they are viewed as costly and inferior lubricants that require much more maintenance and bring their own set of problems. PAGÕs, on the other hand, reduce or eliminate many of the other issues created by conventional EALÕs such as shorter ß uid life, increased maintenance intervals, and ma- chinery damage. Ship operators have long complained that even when using biodegradable oil, they still got Þ ned Þ ne when they spilled it. To that end, they asked, ÒWhat is the point in converting our equipment if we are still go- ing to get Þ ned?Ó Would it not make sense to avoid using oil-based EAL lubricants in applications such as Òoil to sea interfacesÓ in the Þ rst place if there is a viable alternative? PAGÕs offer that viable alternative. The petroleum and lubricant industry often dismiss PAGÕs because they are not compatible with other con- ventional oils and are not produced by major reÞ ners. The main reason for this reluctance of acceptance is lack of knowledge of PAG ß uids and unfamiliarity of the major differences in both environmental compliance reasons and the performance advantages of these ß uids.PAG ß uids such as DowÕs UCON Trident AW, BASF Plurasafe Enbio TC, and American Chemicals Technol- ogyÕs Neptune (including EP and XP) lubricants are an- hydrous, or contain no water, and offer the performance characteristics listed above. PAG ß uids have already solved high heat and varnish issues in harsh applications such as compressor and turbine ß uids, where even PAOÕs were fail- ing due to the severe heat and friction (American Chemi- cal Technologies have now received approval from GE to use PAGÕs in their turbines). Ship owners are now realizing that PAGÕs can offer more than just a solution to the VGP issue but also the beneÞ t PAGÕs can have to their compres- sors and other equipment that are subject to harsh operat- ing conditions in marine environments. PAGs are often said to be very costly but take into account their performance characteristics, their long life, their envi- ronmental footprint, etc., and they can be proven to be less expensive to purchase than most any EAL on the market. If you are worried about having the best performing EAL and worry about your lubricants entering the water or water entering your lubricants, then the use of PAGÕs might be for you. Summing up: if waterÐsoluble PAG ß u-ids are not the perfect biodegradable lubricant, or EAL, they come as close as anything that has been developed to date ever will. REGULATORY Figure A Figure B December 201352 MNMN Dec2013 Layout 50-58.indd 52MN Dec2013 Layout 50-58.indd 5211/25/2013 1:23:46 PM11/25/2013 1:23:46 PM

51

51

53

53