Page 47: of Marine News Magazine (March 2014)

Fleet & Vessel Optimization

Read this page in Pdf, Flash or Html5 edition of March 2014 Marine News Magazine

equipment, the sticker shock is tremendous. In our case, we’re looking at simple cryogenic tanks – cylindrical in construction typically – that is proven technology. That’s the easiest way to get regulatory approvals. And, even though it is new for marine applications, you can point somewhere and say that it works. We’ll incorporate this into our bunker barge designs.”

Jensen’s philosophy is that there is enough risk in these new ventures without introducing unknown variables. Sperling told MarineNews in February, “The Rule of thumb today:

LNG equipment is about double the price of non-LNG com- ponents. We’re talking about the equipment. Whoever moves fi rst takes the most risk because they are going to spend a lot of money and then the prices are going to drop. You don’t want to be fi rst and get it wrong. This has certainly changed but the exponential cost jump is still there for LNG equipment.”

Risk – and Reward

In the beginning, Jensen went forward with its LNG pio- neering efforts for several reasons. Sperling says, “It was a big risk – for a naval architect, time is money and we spent a lot of R&D time on this. In this case, we felt the risk was low enough because we think it’s real enough that someone will eventually pay for it and that’s exactly what has happened.”

Jensen’s LNG design for tugboats got started in 2008.

Since then, a lot of water has gone under the proverbial bridge. Sperling adds, “The engine manufacturers are just now ready to do something. And, as you can see, the fi rst

LNG tug has just been delivered out of a shipyard in Turkey for service in Norway oil fi elds. As you’ve probably seen in all those drawings – the LNG tanks were right underneath the house and accommodations. In the U.S. today, for safe- ty reasons, we are designing vessels that put the LNG tanks somewhere else that is not in the same vertical zone as the accommodations. We have some constraints here that make it trickier for us and U.S. operators in general.”

Design Aspects: uncharted waters

As design professionals move forward on the domestic

LNG front, they are fi nding that there are a lot of rules re- lating to containment that are both published and unpub- lished. Sperling says in regard to the process, “As of today, there’s nothing offi cial that really ties us down. We need to do various things, and yes, we’ll get the approvals. It’s a spe- cial case approval situation. Both DNV and ABS are going to have to work with the Coast Guard. And, we will need to work with them, too. All of us – and the operators, includ- ing Crowley – are leading the charge to defi ne what needs to be done, and that comes with a lot of responsibility. So, it’s important that we do everything possible, from the outset.”

Tug Propulsion: Dual Fuel or LNG?

Jensen’s tug designs are all pure LNG models. Sperling says there are very good reasons for that. “All of our harbor tug designs are gas only. That’s because we know we’ll have read- ily available fuel and the size of the engines currently avail- able are appropriate to that size vessel. As it stands now, with the rules and guidelines we’ve been given, we can’t put large tanks aboard a tugboat without making the tugboat twice as big the others. If that’s the case, the capital cost of the tugboat makes is uneconomical in comparison to conventional.”

Based on Jensen’s popular valor class design, their hard- working vessel will feature a 14-day endurance capability for harbor and escort work and will likely be outfi tted with an innovative LNG package, including two Rolls Royce model

US 255 Z-drives, driven by a pair of Bergen C26:33L6P gas engines. The storage tank will also be supplied by Rolls

Royce (via Cryomar) and the vessel will be fi tted with a hawser winch forward and a capstan aft for line handling.

Head of the Class: who is it?

Jensen’s Sperling hedged a little when it came to declar- ing who would be chosen to provide class on its designs.

Although deep in the heart of ABS country, it is also true that DNV has more LNG experience abroad. Because of that, he added, “ABS is doing a great job of catching up and they are doing their very best to make sure that they get to keep the market for small tugs, bunker barges and similar tonnages. I can’t tell you for sure that our designs or those of others are going to wind up being ABS. Right now, it’s a race between the two of them. In most things, whoever is fi rst stands a good chance of being the experts or they could be the goat. In this case, DNV is riding that

North Sea wave that they helped pioneer.”

Performance: Does LNG stack up to Diesel?

Jensen’s position on LNG tugs is that they have to make

LNG VESSEL DESIGN

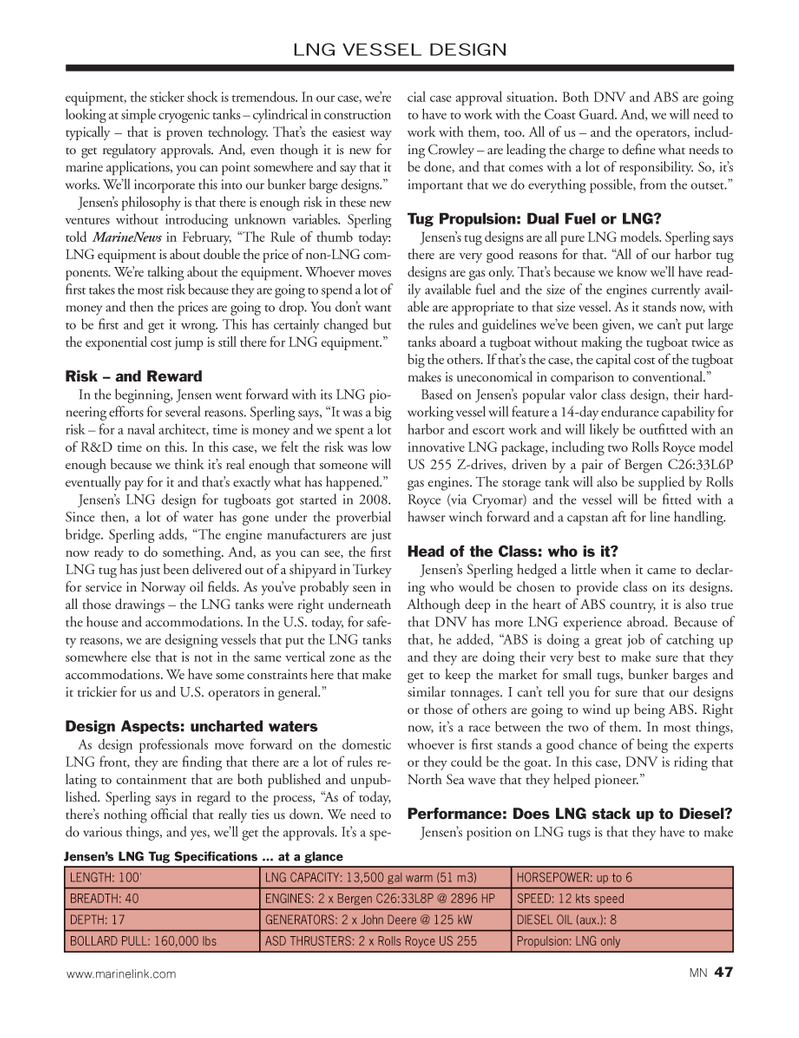

LENGTH: 100' LNG CAPACITY: 13,500 gal warm (51 m3) HORSEPOWER: up to 6

BREADTH: 40 ENGINES: 2 x Bergen C26:33L8P @ 2896 HP SPEED: 12 kts speed

DEPTH: 17 GENERATORS: 2 x John Deere @ 125 kW DIESEL OIL (aux.): 8

BOLLARD PULL: 160,000 lbs ASD THRUSTERS: 2 x Rolls Royce US 255 Propulsion: LNG only

Jensen’s LNG Tug Specifi cations … at a glance www.marinelink.com MN 47

MN MAR14 Layout 32-49.indd 47 2/21/2014 3:29:47 PM

46

46

48

48