Page 48: of Marine News Magazine (September 2014)

Inland Waterways

Read this page in Pdf, Flash or Html5 edition of September 2014 Marine News Magazine

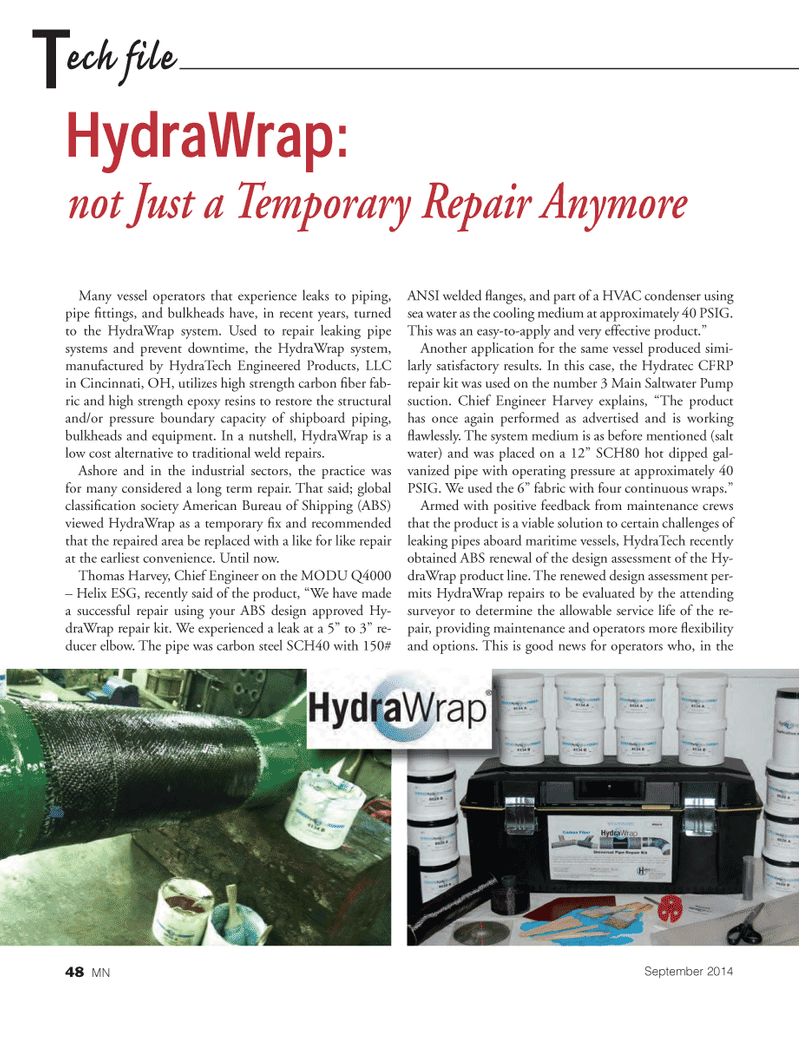

Many vessel operators that experience leaks to piping, pipe Þ ttings, and bulkheads have, in recent years, turned to the HydraWrap system. Used to repair leaking pipe systems and prevent downtime, the HydraWrap system, manufactured by HydraTech Engineered Products, LLC in Cincinnati, OH, utilizes high strength carbon Þ ber fab- ric and high strength epoxy resins to restore the structural and/or pressure boundary capacity of shipboard piping, bulkheads and equipment. In a nutshell, HydraWrap is a low cost alternative to traditional weld repairs. Ashore and in the industrial sectors, the practice was for many considered a long term repair. That said; global classiÞ cation society American Bureau of Shipping (ABS) viewed HydraWrap as a temporary Þ x and recommended that the repaired area be replaced with a like for like repair at the earliest convenience. Until now. Thomas Harvey, Chief Engineer on the MODU Q4000 Ð Helix ESG, recently said of the product, ÒWe have made a successful repair using your ABS design approved Hy- draWrap repair kit. We experienced a leak at a 5Ó to 3Ó re- ducer elbow. The pipe was carbon steel SCH40 with 150# ANSI welded ß anges, and part of a HVAC condenser using sea water as the cooling medium at approximately 40 PSIG. This was an easy-to-apply and very effective product.Ó Another application for the same vessel produced simi- larly satisfactory results. In this case, the Hydratec CFRP repair kit was used on the number 3 Main Saltwater Pump suction. Chief Engineer Harvey explains, ÒThe product has once again performed as advertised and is working ß awlessly. The system medium is as before mentioned (salt water) and was placed on a 12Ó SCH80 hot dipped gal-vanized pipe with operating pressure at approximately 40 PSIG. We used the 6Ó fabric with four continuous wraps.Ó Armed with positive feedback from maintenance crews that the product is a viable solution to certain challenges of leaking pipes aboard maritime vessels, HydraTech recently obtained ABS renewal of the design assessment of the Hy- draWrap product line. The renewed design assessment per- mits HydraWrap repairs to be evaluated by the attending surveyor to determine the allowable service life of the re- pair, providing maintenance and operators more ß exibility and options. This is good news for operators who, in the HydraWrap: not Just a Temporary Repair Anymore Tech file 48 MNSeptember 2014MN Sept14 Layout 32-49.indd 48MN Sept14 Layout 32-49.indd 488/20/2014 11:40:32 AM8/20/2014 11:40:32 AM

47

47

49

49