Page 39: of Marine News Magazine (January 2015)

Passenger Vessels & Ferries

Read this page in Pdf, Flash or Html5 edition of January 2015 Marine News Magazine

BOATBUILDING

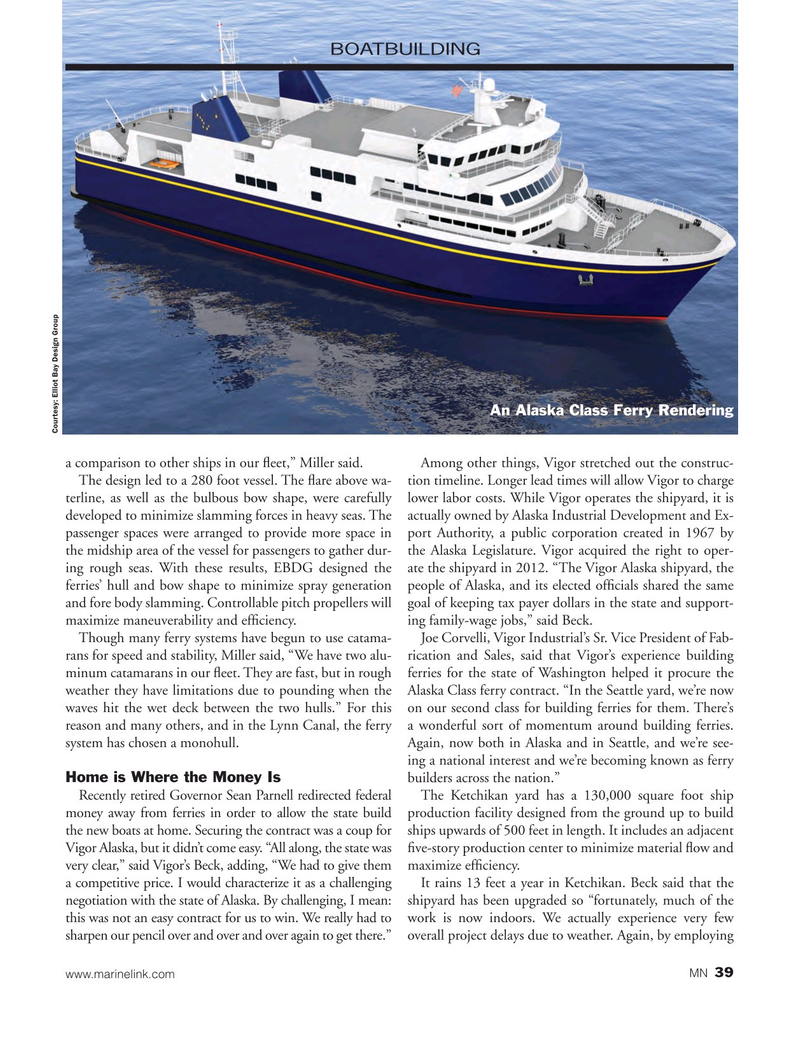

An Alaska Class Ferry Rendering

Courtesy: Elliot Bay Design Group a comparison to other ships in our ? eet,” Miller said. Among other things, Vigor stretched out the construc-

The design led to a 280 foot vessel. The ? are above wa- tion timeline. Longer lead times will allow Vigor to charge terline, as well as the bulbous bow shape, were carefully lower labor costs. While Vigor operates the shipyard, it is developed to minimize slamming forces in heavy seas. The actually owned by Alaska Industrial Development and Ex- passenger spaces were arranged to provide more space in port Authority, a public corporation created in 1967 by the midship area of the vessel for passengers to gather dur- the Alaska Legislature. Vigor acquired the right to oper- ing rough seas. With these results, EBDG designed the ate the shipyard in 2012. “The Vigor Alaska shipyard, the ferries’ hull and bow shape to minimize spray generation people of Alaska, and its elected of? cials shared the same and fore body slamming. Controllable pitch propellers will goal of keeping tax payer dollars in the state and support- maximize maneuverability and ef? ciency. ing family-wage jobs,” said Beck.

Though many ferry systems have begun to use catama- Joe Corvelli, Vigor Industrial’s Sr. Vice President of Fab- rans for speed and stability, Miller said, “We have two alu- rication and Sales, said that Vigor’s experience building minum catamarans in our ? eet. They are fast, but in rough ferries for the state of Washington helped it procure the weather they have limitations due to pounding when the Alaska Class ferry contract. “In the Seattle yard, we’re now waves hit the wet deck between the two hulls.” For this on our second class for building ferries for them. There’s reason and many others, and in the Lynn Canal, the ferry a wonderful sort of momentum around building ferries. system has chosen a monohull. Again, now both in Alaska and in Seattle, and we’re see- ing a national interest and we’re becoming known as ferry

Home is Where the Money Is builders across the nation.”

Recently retired Governor Sean Parnell redirected federal The Ketchikan yard has a 130,000 square foot ship money away from ferries in order to allow the state build production facility designed from the ground up to build the new boats at home. Securing the contract was a coup for ships upwards of 500 feet in length. It includes an adjacent

Vigor Alaska, but it didn’t come easy. “All along, the state was ? ve-story production center to minimize material ? ow and very clear,” said Vigor’s Beck, adding, “We had to give them maximize ef? ciency.

a competitive price. I would characterize it as a challenging It rains 13 feet a year in Ketchikan. Beck said that the negotiation with the state of Alaska. By challenging, I mean: shipyard has been upgraded so “fortunately, much of the this was not an easy contract for us to win. We really had to work is now indoors. We actually experience very few sharpen our pencil over and over and over again to get there.” overall project delays due to weather. Again, by employing 39 www.marinelink.com MN

MN Jan15 Layout 32-49.indd 39 MN Jan15 Layout 32-49.indd 39 12/22/2014 3:13:24 PM12/22/2014 3:13:24 PM

38

38

40

40