Page 48: of Marine News Magazine (October 2015)

Salvage & Spill Response

Read this page in Pdf, Flash or Html5 edition of October 2015 Marine News Magazine

ech file

T

Elastec’s Offshore Oil Spill

Recovery System

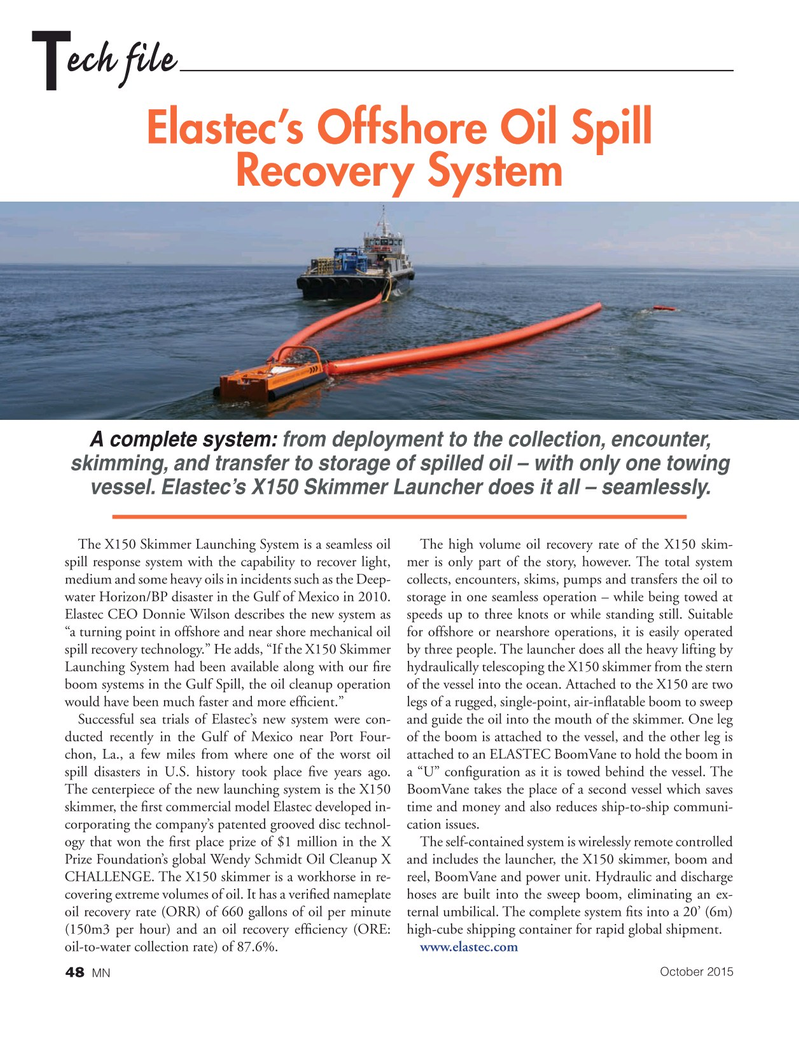

A complete system: from deployment to the collection, encounter, skimming, and transfer to storage of spilled oil – with only one towing vessel. Elastec’s X150 Skimmer Launcher does it all – seamlessly.

The X150 Skimmer Launching System is a seamless oil The high volume oil recovery rate of the X150 skim- spill response system with the capability to recover light, mer is only part of the story, however. The total system medium and some heavy oils in incidents such as the Deep- collects, encounters, skims, pumps and transfers the oil to water Horizon/BP disaster in the Gulf of Mexico in 2010. storage in one seamless operation – while being towed at

Elastec CEO Donnie Wilson describes the new system as speeds up to three knots or while standing still. Suitable “a turning point in offshore and near shore mechanical oil for offshore or nearshore operations, it is easily operated spill recovery technology.” He adds, “If the X150 Skimmer by three people. The launcher does all the heavy lifting by

Launching System had been available along with our ? re hydraulically telescoping the X150 skimmer from the stern boom systems in the Gulf Spill, the oil cleanup operation of the vessel into the ocean. Attached to the X150 are two would have been much faster and more ef? cient.” legs of a rugged, single-point, air-in? atable boom to sweep

Successful sea trials of Elastec’s new system were con- and guide the oil into the mouth of the skimmer. One leg ducted recently in the Gulf of Mexico near Port Four- of the boom is attached to the vessel, and the other leg is chon, La., a few miles from where one of the worst oil attached to an ELASTEC BoomVane to hold the boom in spill disasters in U.S. history took place ? ve years ago. a “U” con? guration as it is towed behind the vessel. The

The centerpiece of the new launching system is the X150 BoomVane takes the place of a second vessel which saves skimmer, the ? rst commercial model Elastec developed in- time and money and also reduces ship-to-ship communi- corporating the company’s patented grooved disc technol- cation issues.

ogy that won the ? rst place prize of $1 million in the X The self-contained system is wirelessly remote controlled

Prize Foundation’s global Wendy Schmidt Oil Cleanup X and includes the launcher, the X150 skimmer, boom and

CHALLENGE. The X150 skimmer is a workhorse in re- reel, BoomVane and power unit. Hydraulic and discharge covering extreme volumes of oil. It has a veri? ed nameplate hoses are built into the sweep boom, eliminating an ex- oil recovery rate (ORR) of 660 gallons of oil per minute ternal umbilical. The complete system ? ts into a 20’ (6m) (150m3 per hour) and an oil recovery ef? ciency (ORE: high-cube shipping container for rapid global shipment. oil-to-water collection rate) of 87.6%. www.elastec.com

October 2015 48 MN

MN Oct15 Layout 32-49.indd 48 9/21/2015 11:28:15 AM

47

47

49

49