Page 36: of Marine News Magazine (December 2015)

Innovative Products & Boats of 2015

Read this page in Pdf, Flash or Html5 edition of December 2015 Marine News Magazine

VESSELS erator engines, with less vibration and noise along with

EASTERN SHIPBUILDING power management and automation. This results in lower operating costs, system redundancy, increased safety, in- creased crew comfort and less crew fatigue.

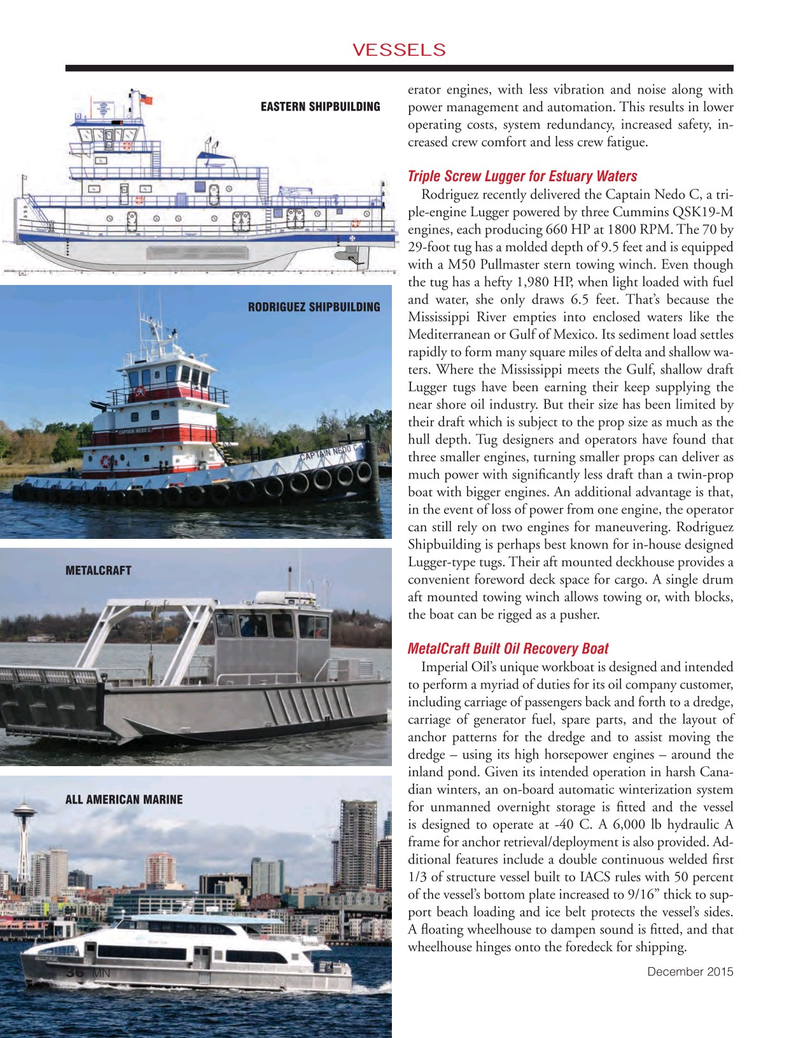

Triple Screw Lugger for Estuary Waters

Rodriguez recently delivered the Captain Nedo C, a tri- ple-engine Lugger powered by three Cummins QSK19-M engines, each producing 660 HP at 1800 RPM. The 70 by 29-foot tug has a molded depth of 9.5 feet and is equipped with a M50 Pullmaster stern towing winch. Even though the tug has a hefty 1,980 HP, when light loaded with fuel and water, she only draws 6.5 feet. That’s because the

RODRIGUEZ SHIPBUILDING

Mississippi River empties into enclosed waters like the

Mediterranean or Gulf of Mexico. Its sediment load settles rapidly to form many square miles of delta and shallow wa- ters. Where the Mississippi meets the Gulf, shallow draft

Lugger tugs have been earning their keep supplying the near shore oil industry. But their size has been limited by their draft which is subject to the prop size as much as the hull depth. Tug designers and operators have found that three smaller engines, turning smaller props can deliver as much power with signi? cantly less draft than a twin-prop boat with bigger engines. An additional advantage is that, in the event of loss of power from one engine, the operator can still rely on two engines for maneuvering. Rodriguez

Shipbuilding is perhaps best known for in-house designed

Lugger-type tugs. Their aft mounted deckhouse provides a

METALCRAFT convenient foreword deck space for cargo. A single drum aft mounted towing winch allows towing or, with blocks, the boat can be rigged as a pusher.

MetalCraft Built Oil Recovery Boat

Imperial Oil’s unique workboat is designed and intended to perform a myriad of duties for its oil company customer, including carriage of passengers back and forth to a dredge, carriage of generator fuel, spare parts, and the layout of anchor patterns for the dredge and to assist moving the dredge – using its high horsepower engines – around the inland pond. Given its intended operation in harsh Cana- dian winters, an on-board automatic winterization system

ALL AMERICAN MARINE for unmanned overnight storage is ? tted and the vessel is designed to operate at -40 C. A 6,000 lb hydraulic A frame for anchor retrieval/deployment is also provided. Ad- ditional features include a double continuous welded ? rst 1/3 of structure vessel built to IACS rules with 50 percent of the vessel’s bottom plate increased to 9/16” thick to sup- port beach loading and ice belt protects the vessel’s sides.

A ? oating wheelhouse to dampen sound is ? tted, and that wheelhouse hinges onto the foredeck for shipping.

December 2015

MN 36

MN Dec15 Layout 32-49.indd 36 11/24/2015 9:34:16 AM

35

35

37

37