Page 38: of Marine News Magazine (December 2015)

Innovative Products & Boats of 2015

Read this page in Pdf, Flash or Html5 edition of December 2015 Marine News Magazine

VESSELS tion, BCGP’s parent, does own Mercury. In an effort to ing; and high-energy absorption Schuyler fendering.

help customers maintain ? eet continuity, a wide range of engine options – from outboards to inboards – is available. Blount Boats Wind Farm Supply Vessels

Blount Boats earlier this year signed a contract with Rhode

Vigor-built State-of-the-Art Towboat for Tidewater Island Fast Ferry for the construction of a 21 meter crew

The Crown Point is an environmentally-friendly tug with transfer vessel (CTV) that will operate for Deepwater Wind reduced air emissions and improved fuel ef? ciency. Designed Block Island. The 21 meter aluminum vessel was designed by CT Marine, Naval Architects and Marine Engineers of by South Boats IOW (Isle of Wight). In 2011, Blount Boats

Edgecomb, Maine, the vessel features a wheelhouse with ex- signed a licensing agreement with South Boats to become ceptional all-round visibility through full height windows, the exclusive shipyard to manufacture U.S. Flagged alumi- leading edge navigation and communications equipment, num catamarans of South Boats IOW designs for the U.S. and enhanced accommodations for the captain and crew. wind farm industry. The South Boats’ designed stock 21m

The vessel has been deployed in Tidewater’s Columbia & wind farm vessel is a twin hulled, all aluminum catamaran.

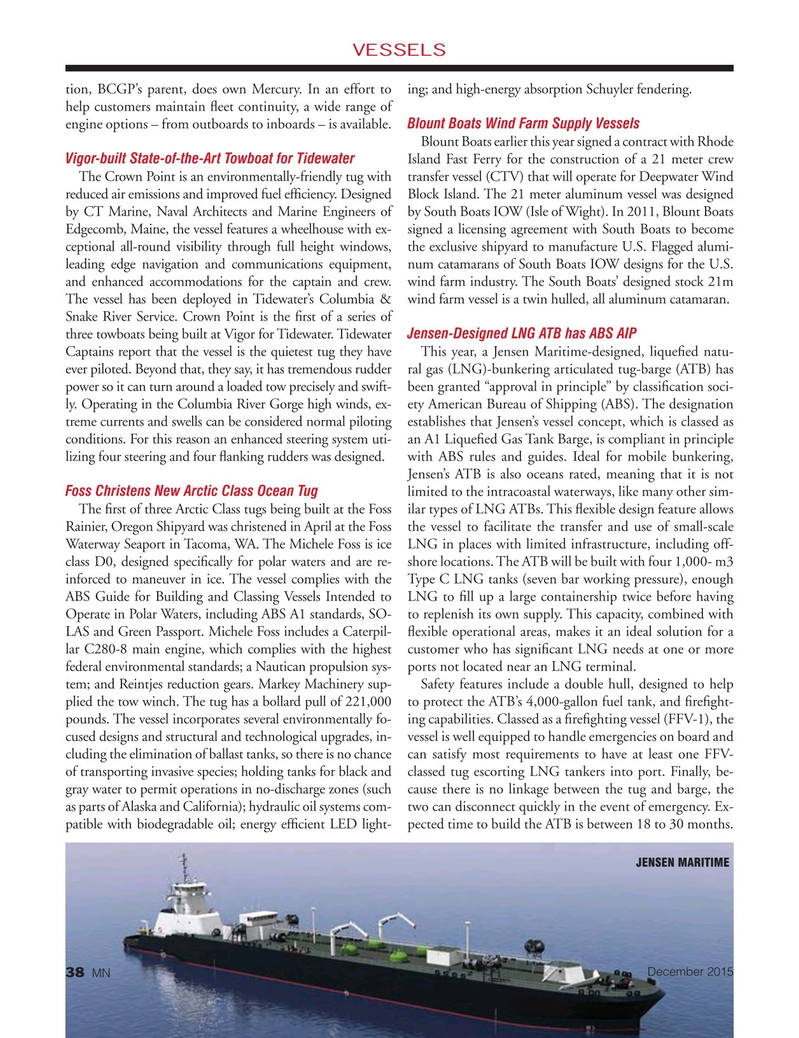

Snake River Service. Crown Point is the ? rst of a series of three towboats being built at Vigor for Tidewater. Tidewater Jensen-Designed LNG ATB has ABS AIP

Captains report that the vessel is the quietest tug they have This year, a Jensen Maritime-designed, lique? ed natu- ever piloted. Beyond that, they say, it has tremendous rudder ral gas (LNG)-bunkering articulated tug-barge (ATB) has power so it can turn around a loaded tow precisely and swift- been granted “approval in principle” by classi? cation soci- ly. Operating in the Columbia River Gorge high winds, ex- ety American Bureau of Shipping (ABS). The designation treme currents and swells can be considered normal piloting establishes that Jensen’s vessel concept, which is classed as conditions. For this reason an enhanced steering system uti- an A1 Lique? ed Gas Tank Barge, is compliant in principle lizing four steering and four ? anking rudders was designed. with ABS rules and guides. Ideal for mobile bunkering,

Jensen’s ATB is also oceans rated, meaning that it is not

Foss Christens New Arctic Class Ocean Tug limited to the intracoastal waterways, like many other sim-

The ? rst of three Arctic Class tugs being built at the Foss ilar types of LNG ATBs. This ? exible design feature allows

Rainier, Oregon Shipyard was christened in April at the Foss the vessel to facilitate the transfer and use of small-scale

Waterway Seaport in Tacoma, WA. The Michele Foss is ice LNG in places with limited infrastructure, including off- class D0, designed speci? cally for polar waters and are re- shore locations. The ATB will be built with four 1,000- m3 inforced to maneuver in ice. The vessel complies with the Type C LNG tanks (seven bar working pressure), enough

ABS Guide for Building and Classing Vessels Intended to LNG to ? ll up a large containership twice before having

Operate in Polar Waters, including ABS A1 standards, SO- to replenish its own supply. This capacity, combined with

LAS and Green Passport. Michele Foss includes a Caterpil- ? exible operational areas, makes it an ideal solution for a lar C280-8 main engine, which complies with the highest customer who has signi? cant LNG needs at one or more federal environmental standards; a Nautican propulsion sys- ports not located near an LNG terminal.

tem; and Reintjes reduction gears. Markey Machinery sup- Safety features include a double hull, designed to help plied the tow winch. The tug has a bollard pull of 221,000 to protect the ATB’s 4,000-gallon fuel tank, and ? re? ght- pounds. The vessel incorporates several environmentally fo- ing capabilities. Classed as a ? re? ghting vessel (FFV-1), the cused designs and structural and technological upgrades, in- vessel is well equipped to handle emergencies on board and cluding the elimination of ballast tanks, so there is no chance can satisfy most requirements to have at least one FFV- of transporting invasive species; holding tanks for black and classed tug escorting LNG tankers into port. Finally, be- gray water to permit operations in no-discharge zones (such cause there is no linkage between the tug and barge, the as parts of Alaska and California); hydraulic oil systems com- two can disconnect quickly in the event of emergency. Ex- patible with biodegradable oil; energy ef? cient LED light- pected time to build the ATB is between 18 to 30 months.

JENSEN MARITIME

December 2015 38

MN

MN Dec15 Layout 32-49.indd 38 11/24/2015 9:34:50 AM

37

37

39

39